EN • 11

ENGLISHFRANCAISNEDERLANDSESpAñoLITALIANoDEuTSCH

664Y0200.C

CircuitdiagramofACVcontrolkits

B2. Temperature sensor

B9. Outdoor sensor

B5. Analog/digital room sensor

P1. Pump

Y1/Y2/N. Servomotor (SSY 319 or SQY 349)

bl. Blue N

n/z. Black Y2

br. Brown Y1

20 19 18 17 16 15 14 13 12 11 10 98765432 1

20 19 18 17 16 15 14 13 12 11 10 98765432 1

bl

bk br

SSY 319 / SQK 349

QAAD50

(QAAD70)

QAC32 QAD22

P1 B5 B9 B3 B2

P1Y1Y2NB5B9B3B2

Pleasecontactyourinstallerforfurtherdetailsabout

this.

GAS CONNECTION

- The boiler is fitted with a 3/4” M connector. It is possible to

connect it to the gas tap.

- The gas connection must be made in accordance with standard

NBN D51-003 and, where applicable, other standards in force

at the place of connection.

- If there is a risk of dirt near the network, fit a gas filter

upstream of the connection.

- Vent the gas pipe and carefully check that all external and

internal boiler pipes are gas tight.

- Check the installation’s gas pressure.

- Check the gas pressure and consumption when commissioning

the appliance.

INSTALLATIoN

CONTROL KIT

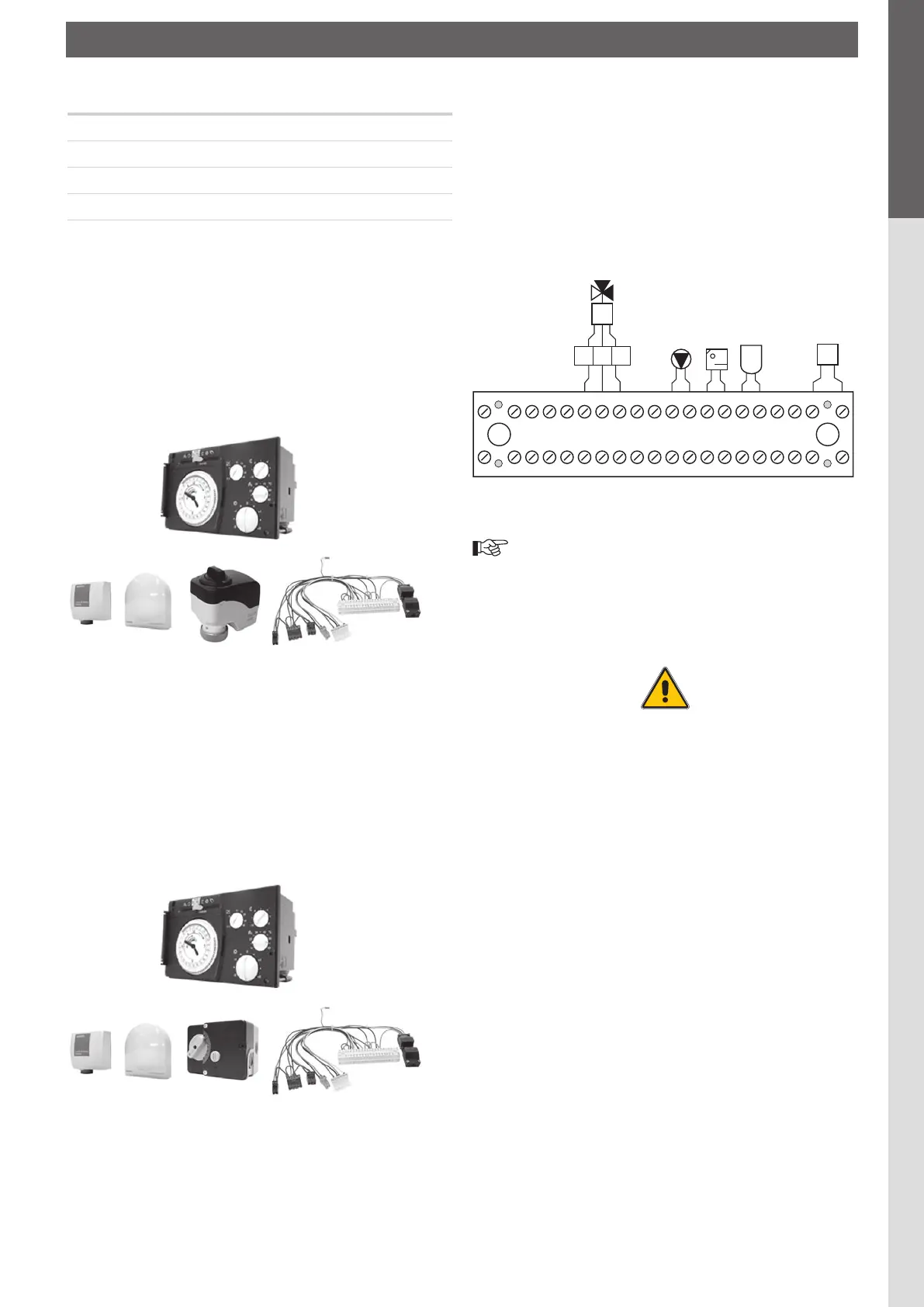

KIT1:ACV13.00/Basic

This basic kit is used to control the hot water circuit outlet

temperature as a function of ambient conditions.

It comprises: a temperature controller with analog clock, a

surfacemounted primary water temperature sensor (-30/130°C),

an outdoor sensor (-30/50°C), a servomotor SSY 319 230 V -

3-pin and intermediate socket.

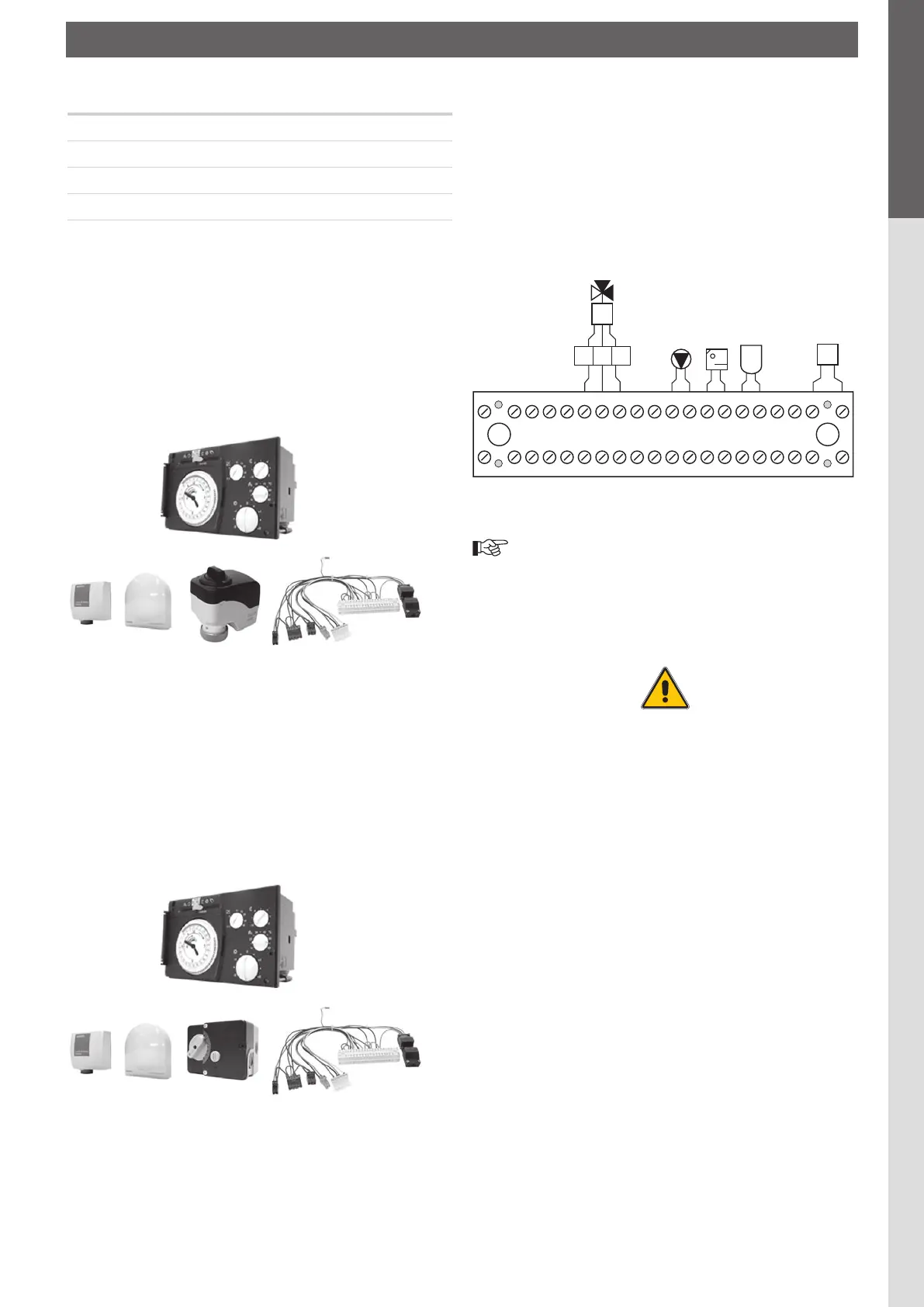

KIT2:ACV13.00/Standard

This Standard kit is used to control the hot water circuit outlet

temperature as a function of ambient conditions.

It comprises: a temperature controller with analog clock, a

surfacemounted primary water temperature sensor (-30/130°C),

an outdoor sensor (-30/50°C), a servomotor SQY 349 230 V -

3-pin and an intermediate socket.

Optionalaccessories

Safety group

Ø 3/4"

Pressure reducing valve

Ø 3/4"

Thermostatic mixer

Ø 3/4"

Expansion vessel

5 litres

Loading...

Loading...