EN • 16

ENGLISHFRANCAISNEDERLANDSESpAñoLITALIANoDEuTSCH

664Y0200.C

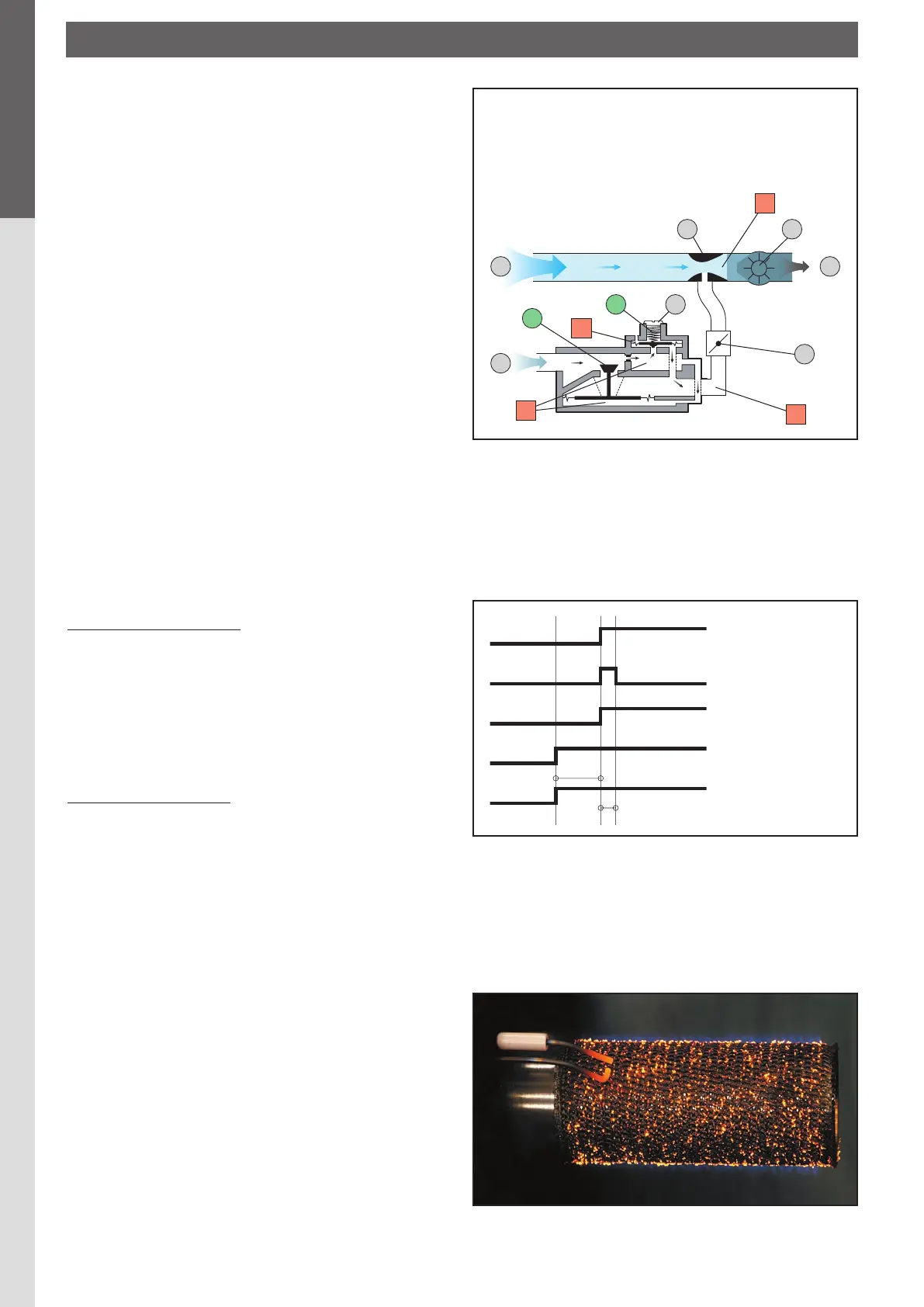

OPERATING PRINCIPLE OF THE BURNER

AIR/GASmixturecontrol(fig.12)

The fan draws air in across the venturi. This creates a vacuum

P1 at the venturi neck. The gas valve regulator now reacts to

maintain a difference equal to the amount of the offset between

the pressure at the gas valve outlet P2 and atmospheric

pressure P3 : P2–P3=offset.

If the air flow decreases, P1 rises; the same applies to P2;

now P2>P3; the regulator R moves upwards and restores the

equilibrium P2 – offset = P3; pressure P4 falls and valve C

moves down: the gas flow decreases.

Whatever the speed of the fan therefore, the Air/Gas ratio is

maintained equal to 1 to within the amount of the offset.

The difference in pressure between the neck of the venturi and the

outlet from the gas valve now draws gas through the venturi.

The gas flow adjuster screw is used to adjust the amount of gas

that

is to be injected for a given air flow, and this will determine the

%CO

2 in the flue gas. It is now a very simple matter to control

the burner's power by adjusting the fan speed and the %CO2 to

predefined settings.

Ignitionandflamemonitoring

The control and monitoring relay has a dual function: it ignites

the burner by producing sparks at the ignition electrode, and it

monitors the actual presence of a flame when the gas valve is

open (it measures the ionisation current).

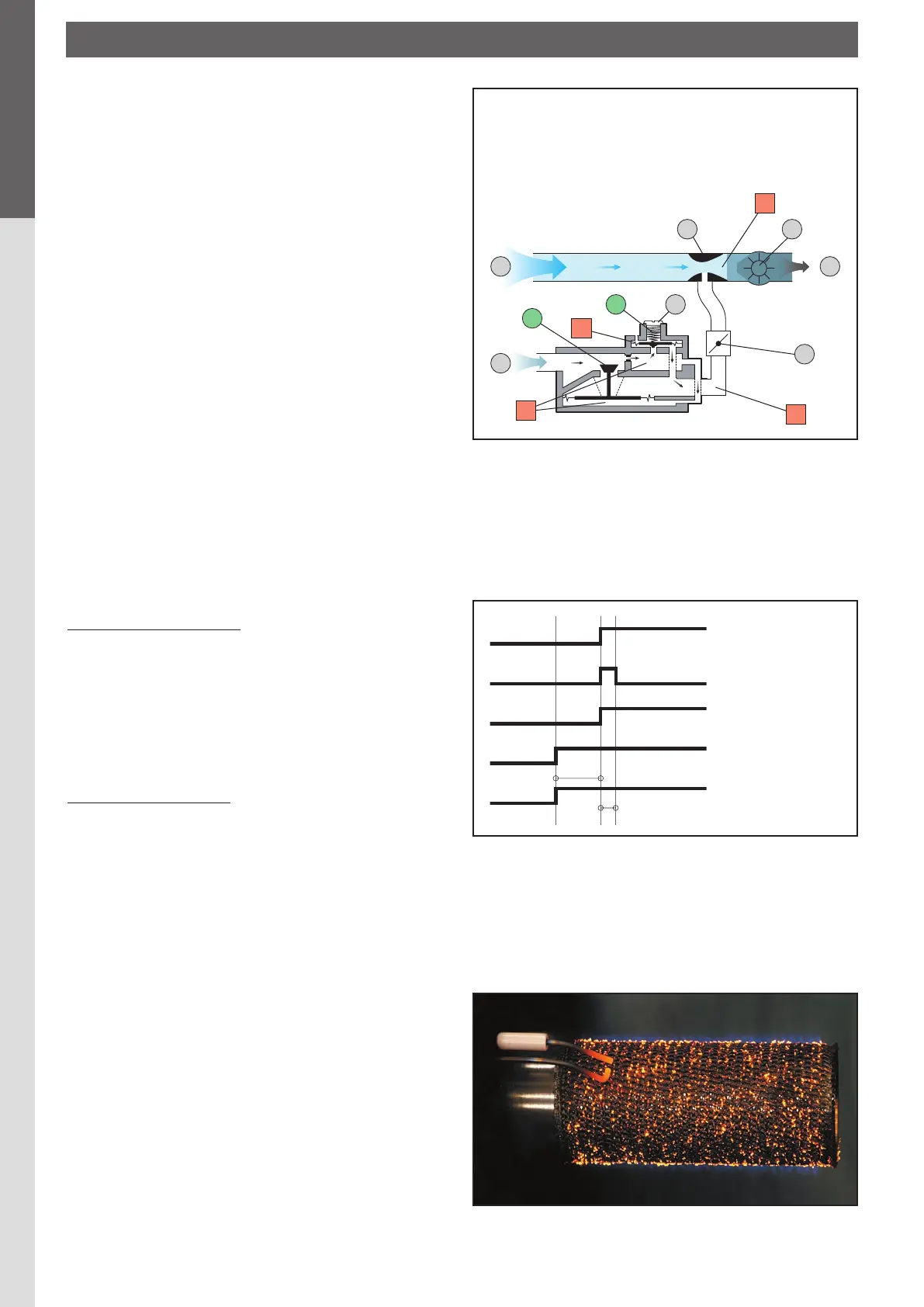

Startingsequence:(fig.13)

The fan starts up when the boiler thermostat/potentiometer

detects a demand for heat. After a 15 second pre-purge the

gas valve opens simultaneously with the ignition. Provided

an ionisation current is detected inside the first 5 seconds,

combustion continues normally until heat is no longer called for.

Otherwise, the gas valve closes and the fan stops; the burner is

now shut down.

Iftheburnershutsdown:

1. The burner indicator lamp lights up on the control panel and

on the burner.

2. Press the burner reset button on the control panel. Turn the

boiler off for several seconds at the main switch, then restart

the the boiler.

Gastube(fig.14)

The air/gas mixture leaving the gas valve/venturi assembly is

propelled into the burner tube.

For Alfa Sprint models M/MV, this tube is covered with metal

fibres (NIT). This enhances the distribution of the flame,

increasing its life and significantly reducing pollutant emissions.

Combustion of the air/gas mixture is also spread uniformly

around the circumference of the tube. The tube is also designed

to withstand propane combustion.

fig. 13 : Starting sequence

Ionisation

Thermostat

Fan

Gas valve opens

Ignition

15s

5s

1. Air

2. Gas

3. Venturi

4. Fan

5. Offset adjuster screw

6. Gas flow adjuster screw (CO2)

7. Air/gas mixture

fig. 12 : Air/gas mixture control

1

7

2

5

R

3

4

6

P1

P2

P3

P4

C

fig. 14 : The NIT gas tube in operation

BuRNER CHARACTERISTICS

Loading...

Loading...