Page 46 of 84

261

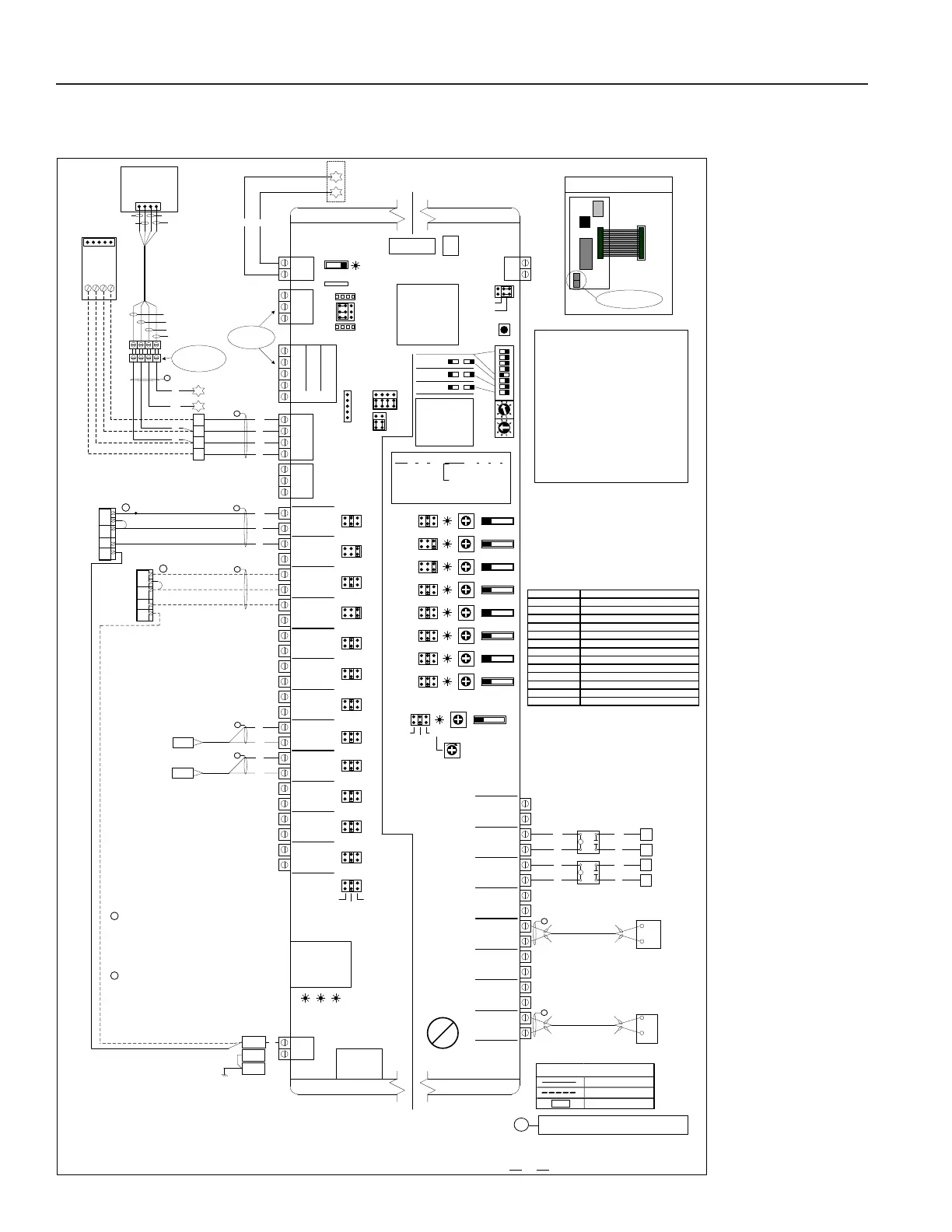

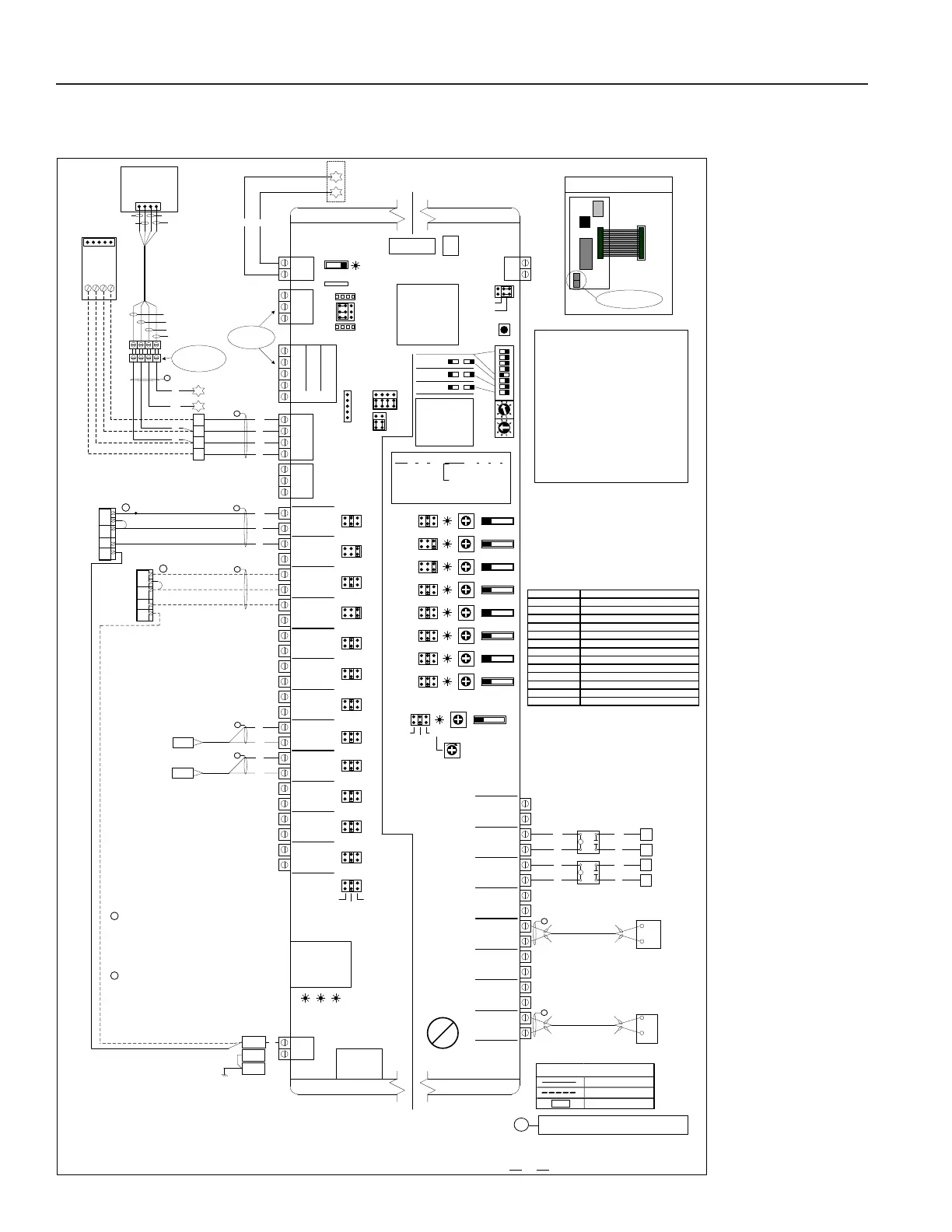

WIRINGDIAGRAM#PrelimWD|PROA180B2A3DEBDBB2B|230‐3‐60|SHEET5OF7|12/10/19DWNCHK.

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

Temp/RH

ZSRoom

Sensor

Off OnAuto

UniversalInput

ModeSelect

AuxPowerOut

Power

Off On

Port1

Rnet

Gnd

RNET+

RNET‐

+12V

UO‐8

UO‐7

UO‐6

UO‐5

Gnd8

UO‐4

+7

Gnd6

UO‐3

+5

Gnd4

UO‐2

+3

Gnd2

UO‐1

+1

Gnd8

+7

Gnd6

+5

Gnd4

+3

Gnd2

+1

UI‐8

UI‐7

UI‐6

UI‐5

8Gnd

UI‐4

7+

6Gnd

UI‐3

5+

4Gnd

UI‐2

3+

2Gnd

UI‐1

1+

UI‐12

UI‐11

UI‐10

UI‐9

RnetLocal

Access

Gnd

Rnet+

Rnet‐

+12V

Sense

8Gnd

7+

6Gnd

5+

4Gnd

3+

2Gnd

1+

8Gnd

7+

6Gnd

5+

4Gnd

3+

2Gnd

1+

Gnd

24VAC

0

5

0

5

12345678

10's

1's

Module

Address

NET+

NET‐

Shield

Port1BT485

Port2aBT485

485Port1

ARC‐

156

2Wire

EIA‐

485

4Wire

EIA‐

232

Port2a

XNET+

XNET‐

Gnd

Port2a

NET+

NET‐

n/c

n/c

SignalGround

Tx+

Tx‐

Rx+

Rx‐

Tx

Rx

DTR

DCD

2wire 4wire EIA‐232

mA

Thermistor/

DryContact/

RTD

Volts

Off

21

Assigned Default

On Off

BASPort

IPAddr

Enhanced

AccessPort2a

BACnet

BASPortSettings

BAUD 4 5 Protocols 6 7 8

9600 Off Off MSTP(m) Off Off Off

19.2K Off On MSTP(s) On Off Off

38.4K On Off PTP Off On Off

76.8K On On N2 On On Off

Modbus Off Off On

LonSLTA On Of f On

LonOption Off On On

Fuse

24VDC

200mAmaximum

100 LAN LINK

10/100BaseT

EthernetPortE1

Xnet

Expansion

SeeBASTableBelow

+3V

Gnd

External

Battery

Ext.Batt.

Int.Batt.

0‐10Vdc

0‐20mA Relay

Pot

UO‐1

UO‐2

UO‐3

UO‐4

UO‐5

UO‐6

UO‐7

UO‐8

SetPotFullCW

Port2b

Format

I/OPRO812u

CONTROLLER

SEETB4ONUNIT

WIRINGDIAGRAM

R

TB4

BL

FA CTORYWIRING

FIELDWIRING

TERMINALBOARD

SYMBOLLEGEND

USE18AWGWIREMINIMUM.TOMINIMIZE

INTERFERENCEPROBLEMS:

USESHIELDEDWIREON ALLANALOGINPUTS

ANDOUPUTS.DONOTRUN0‐10VOLTDC

SIGNALWIRINGINTHESAMECONDUITAS

LINEVOLTAGEWIRINGORWITHWIRING

THATSWITCHESHIGHLYINDUCTIVELOADS

SUCHASCONTACTORANDRELAYCOILS.

GROUNDONEENDOFTHEDRAIN(SHIELD)

WIRE.

WHEN0‐10VOLTDCSIGNALWIRINGMUST

CROSSCLOSETOCABLEORNONMETALLIC

CONDUITCONTAININGLINEVOLTAGE

WIRINGORWIRINGTHATSWITCHESHIGHLY

INDUCTIVELOADS,ITMUSTCROSS

PERPENDICULAR(90DEGREES)TOIT.

KEEPTHE0‐10VOLTDCSIGNALWIRINGAS

SHORTASPOSSIBLE.

LON

1

2

Port2b

ECHELON

LonWorksCard(optional )

FORFIELD:BASOREMS

CONNECTION

3VLitiumBattery

CR‐123A

‐ +

ErrorCodes:

Chase=OK

0=DownloadRequired

1=ControlProgramError

2=RAMfull

3=Commset‐uperror

4=Systemerror

8=Formatting

BlinkingDot=‘Run’

8

.

DONOTAPPLY24VAC

TOUNIVERSALOUTPUTS

External24VDCrelaycoilonly

24VAC

R

TB‐A

GND

GND

24VDC

USESHIELDEDWIREFORALL

ANOLOGINPUTS

WIREALLSHIELDWIRESTOCLOSESTTB‐AorTB‐D

“GND”TERMINALATTHECONTROLPANEL

4

24VDC

4

R

BKBK

R

SF1VFD

AI1

0V

7

6

SupplyFanVFD,

0‐10vdc

4

R

BKBK

R

5

9

HSSR

R

BK

2

nd

StageHeat

W2

R

TB1

GY

BK

4

2

temp

sensor

V

out

com

Vin

pwr

OA‐T/RH

BK

InstallOA‐T/RHunderthe

OAhood,sensingthe

ambienttemp/humidity.

2

G

DxLAT2:INSTALLAFTERDXCOIL

#2UPSTREAMOFREHEATCOIL

DxLAT1

R

BK

DxLAT1:INSTALLAFTERDXCOIL

#1UPSTREAMOFREHEATCOIL

SA‐T/RH

Fieldinstall

andwire

1

temp

sensor

V

out

com

Vin

pwr

4

Note:THESUPPLY/DISCHARGEAIRTEMPERATURE/RELITIVEHUMIDITY

(SA‐T/RH)ISFACTORYSUPPLIEDFORFIELDINSTALLATIONINSUPPLYAIR

DUCT.SENSORMUSTBEINSTALLEDDOWNSTREAMOFHEATERWHERE

ITCANNOT“SEE”ANYHEATINGELEMENTSANDWHERESUFFICIENT

MIXINGOFDISCHARGEAIROCCURS.USE18AWGSHIELDEDWIRE.DO

NOTRUNSENSORWIRINGINTHESAMECONDUITASLINEVOLTAGE

WIRINGORWITHWIRINGTHATSWITCHESHIGHLYINDUCTIVELOADS

SUCHASCONTACTORANDRELAYCOILS.

1

W

4

DxLAT2

R

BK

4

SENSORS DESCRIPTION

CFI Clo

edFilterIndicator

DPT‐260 DifferentialPressureTransmitter

SA

Su

l

AirTem

eratureSensor

OA‐T

R

OutdoorAirTem

RelativeHumidit

Sensor

SA‐R

Su

l

AirRelativeHumidit

ZS ZoneTem

eratureSensor‐Standar

CC1‐CS

CC2‐CS Com

ressor#1CurrentSensor

DxLAT DxLeavin

AirTem

er at ureSensor

WM‐CS WheelMotorCurrentSensor

SF‐APS

EF‐APS Su

l

Fan

Exhaust FanAirPress.Swit c

WFR WaterFlowRela

LP1

LP2 LowPressureSwitch

Ckt.#1

S

SmokeDetector

K3

K4

14

13

5

9

UnloaderRelay#1

R

PR

Unloader#1

U1

R

TB1

GY

PR

14

13

WARNING!!!

DONOTleavedip

switch#1“ON”.This

willresultinlossof

BACviewandnetwork

communications.

MRC

+S

‐S

Modulating

Reheat,0‐10vdc

Gnd

RNET+

RNET‐

+12V

Gnd

Rnet+

Rnet‐

+12V

Sense

Black

Red

G

W

Green

EQUIPMENT

TOUCH

Gnd

Rnet+

Rnet‐

+24VAC

Red

Black

White

FIELDINSTALL

4

K3

K4

‐12V

Rnet

+

Rnet

‐

+12V

TB4

TB5

ToWallMountthe

EquipmentTouchremove

thefactoryinstalledcable

andwire+24VACtoTB4“K3”

andwireGndtoTB4“K4”.If

thereisaZSsensorinstalled

wireRnet+andRnet‐tothe

ZSsensorRnet+andRnet–

terminals,otherwisewireto

TB5Rnet+andRnet‐

BK

G

W

R

4

BK

R

EquipmentTouch

Connector

(Blue)

White

Green

FORFIELD:

BACNET

CONNECTION

ALLFIELDINSTALLEDSENSORSSHOULDBEWIREDTOTHE

CONTROLLERFORFACTORYTESTINGWITHTEMPORARY

WIRINGANDLEFTINTHEUNITAFTERTEST.TEMPORARY

WIRINGSHOULDBEREMOVEDFORPERMANENT

INSTALLATIONDURINGUNITINSTALLATION.LABEL

SENSORSPERTHEWIRINGDIAGRAM.

Figure 17e: Typical Electrical Wiring Diagram

PR Series Installation, Operation, and Maintenance Manual

Loading...

Loading...