GATE OPERATOR INSTALLATION

PREINSTALLATION GUIDELINES:

Before starting any installation, consider the following guidelines:

• Install the gate system and gate in accordance with ASTM F220-02: Standard Specification for Automated Vehicular Gate

Construction. Install the gate system and gate in accordance with UL325 standards.

• Be sure the gate is properly installed and moves freely. Repair or replace worn or damaged gate hardware before installing the gate

operator.

• Install over-travel stops at both ends of the gate rail or track for all types of installations to help prevent the gate from derailing.

• Add safety devices such as warning signs, photo eyes, and reverse edges to help prevent injuries or death. Reduce all pinch points

and protect all entrapment positions.

• If pedestrian traffic will be present, provide a separate pedestrian walk gate clear from the path of the automatic gate.

• Loops and loop detectors are required to help prevent the gate from closing on vehicles. Loops do not protect pedestrian traffic.

• Select the proper gate operator for the installation. Consider the usage, capacity, gate size, gate weight, and needed features and

safety accessories.

GATE OPERATOR LOCATION:

Select a location for the gate operator to be installed prior to pouring the concrete pad. There are two ways to mount a slide

gate operator: the traditional front mount, or the rear mount method. Both methods have their advantages and will reliably

open the gate.

WARNING: Install over-travel stops at both ends of the gate rail or track for all types

of installations to help prevent the gate from derailing.

!

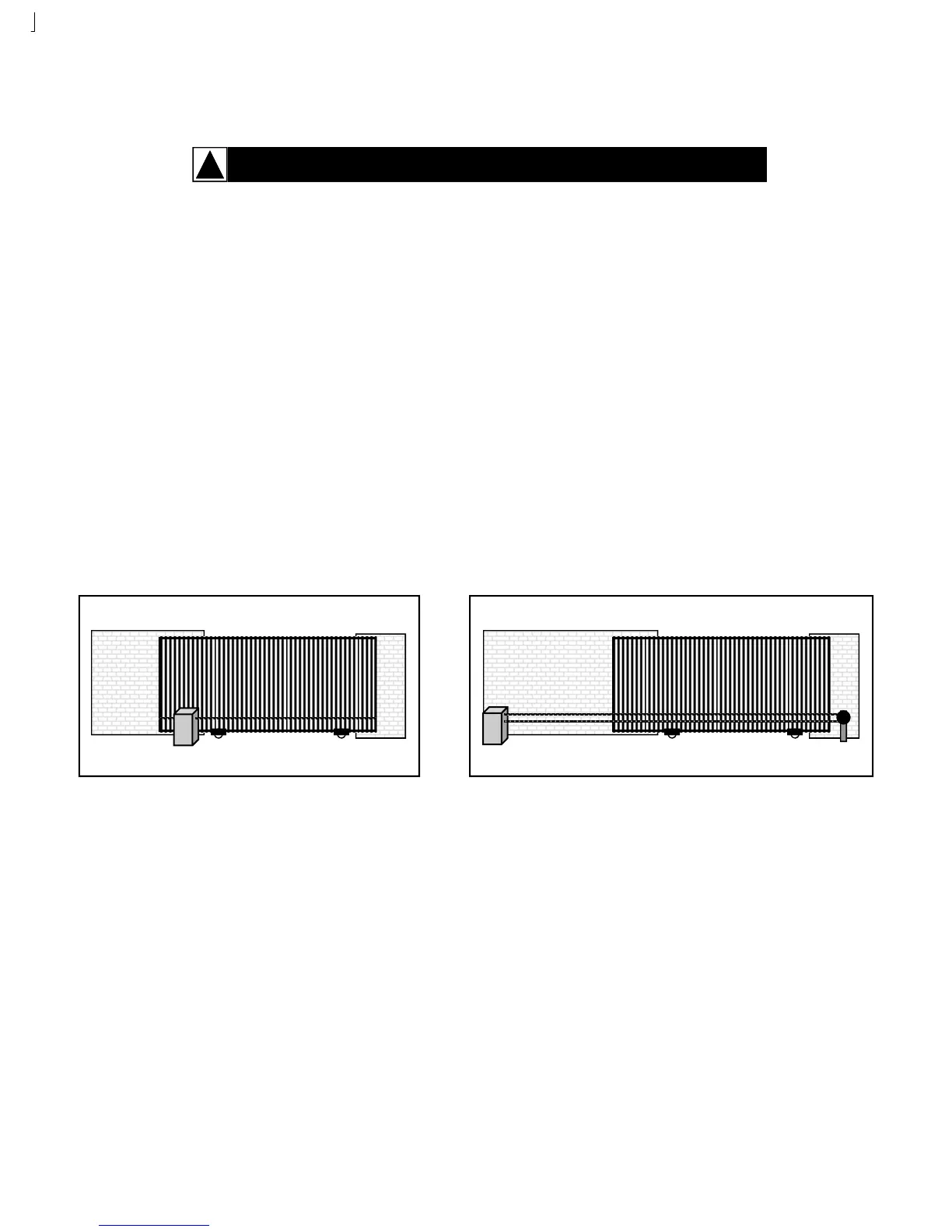

REAR MOUNT METHOD:

A rear mount installation places the operator at the back of the

gate and uses a double chain with an additional idler sprocket.

The advantages and disadvantages include:

Advantages:

• The chain is attached to the rear of the gate and is not

visible when the gate is closed.

• The operator is in the back away from the flow of traffic for

added safety.

• The operator is in the back allowing more room for tight

parking conditions.

Disadvantages:

• Twice as much chain is required for this type of application

= added expense.

• The application requires the use of an additional idler

sprocket = added expense.

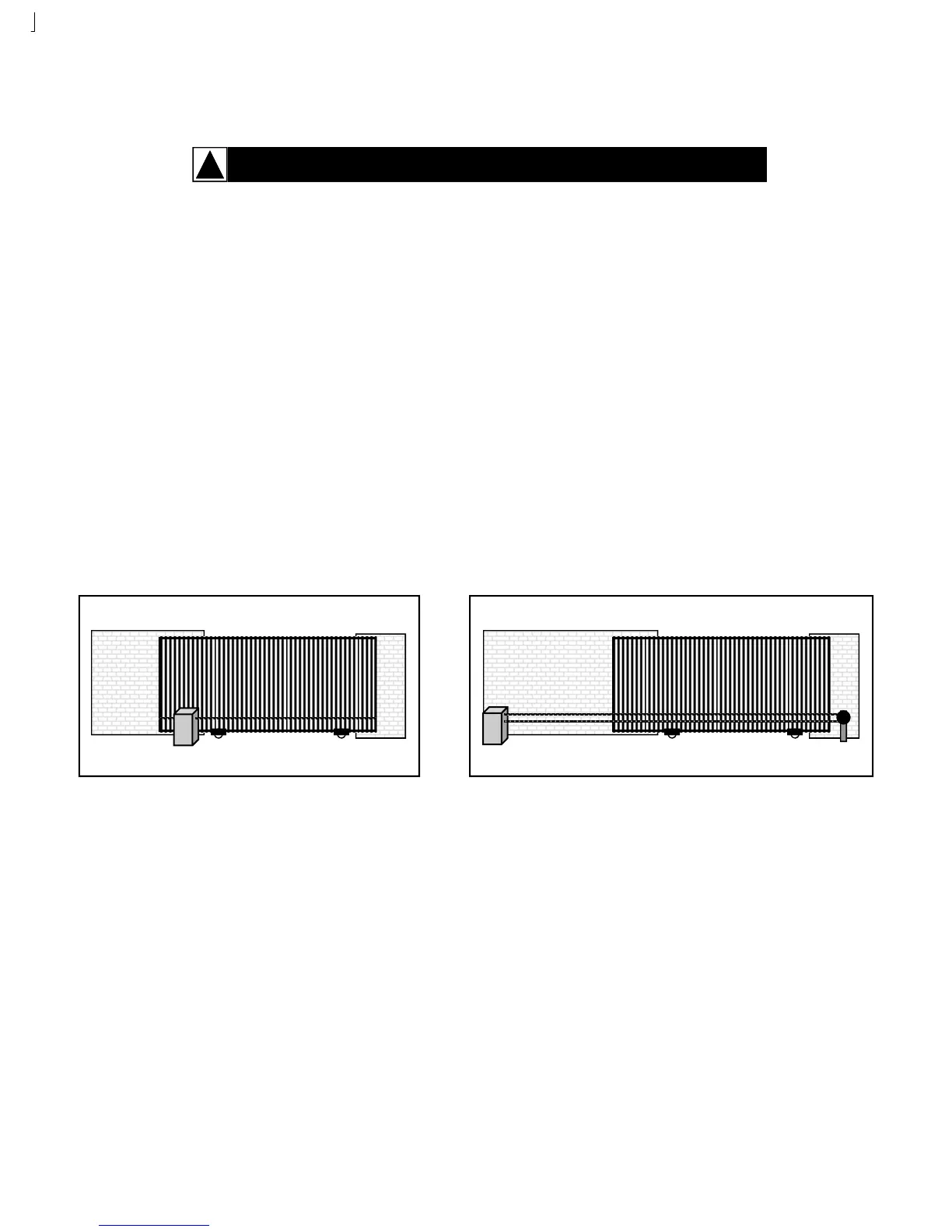

FRONT MOUNT METHOD:

The front mount method places the operator up front near

the flow of traffic and uses a single chain across the length

of the gate. The advantages and disadvantages include:

Advantages:

• Less chain is required for the application saving money

and time.

• Does not require the use of an additional idler sprocket

saving money and time.

• Less room is needed for the application and allowing the

operator to be more accessible for service.

Disadvantages:

• The operator is up front near the flow of traffic allowing

for a vehicle to damage the operator more easily.

• The chain runs across the length of the gate allowing

visitors to see and possible tamper with it.

Loading...

Loading...