Page 19 of 30 AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, New York 10913 • Phone: 800-526-0288 PR1 04/08/2014

Application Guide

3. CONNECTIONS

3.1. PRIMARY-SECONDARY PIPING

Primary-secondary piping must be utilized. This can be accomplished by using a common pipe (see

Figures 11, 13, 15, 17) or a hydraulic separator. Primary – secondary piping decouples the boiler loop

from the system loop, making it independent from system loop pressure fluctuations associated with

opening/closing of zone valves or 3-way valves.

3.2. SYSTEM FILLING AND DRAINING

The boiler is equipped with its own header drains (see Figures 6a and 6b for the drain locations).

NEVER USE IT TO DRAIN THE ENTIRE SYSTEM, since the system dirt could gather in the boiler

and compromise its operation. The system itself shall be equipped with its own drain, whose size will

depend on the system capacity.

• For filling the system, a filling tap has to be inserted on the system return pipe.

• The filling can also be done through the draining tap on the boiler return manifold

(see drain valve locations in Figure 6a and Figure 6b).

• In both cases, an approved hydraulic disconnection system has to be fitted.

• Before connecting the boiler, carefully rinse out the whole system, as specified in Section 2.3 or

by local code and best practices.

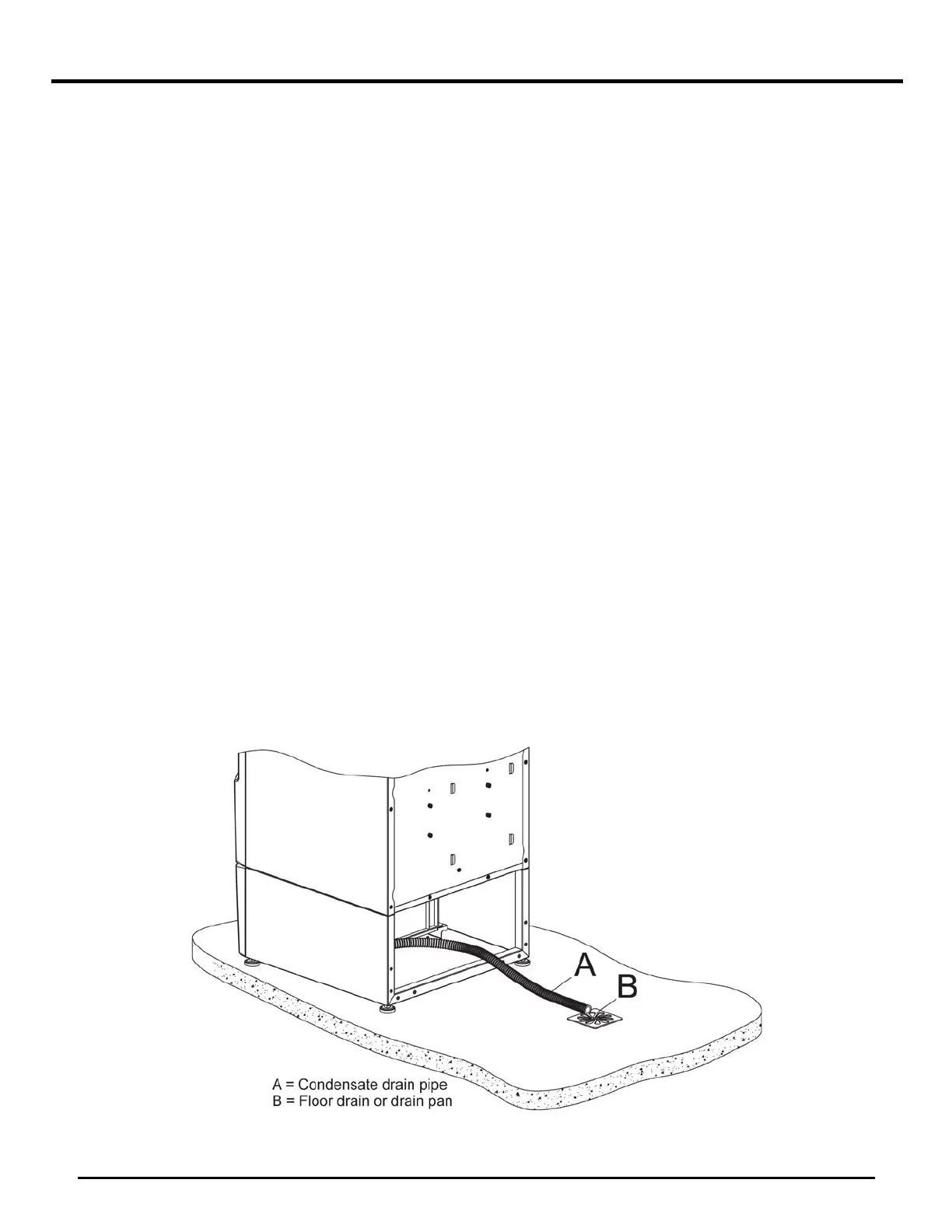

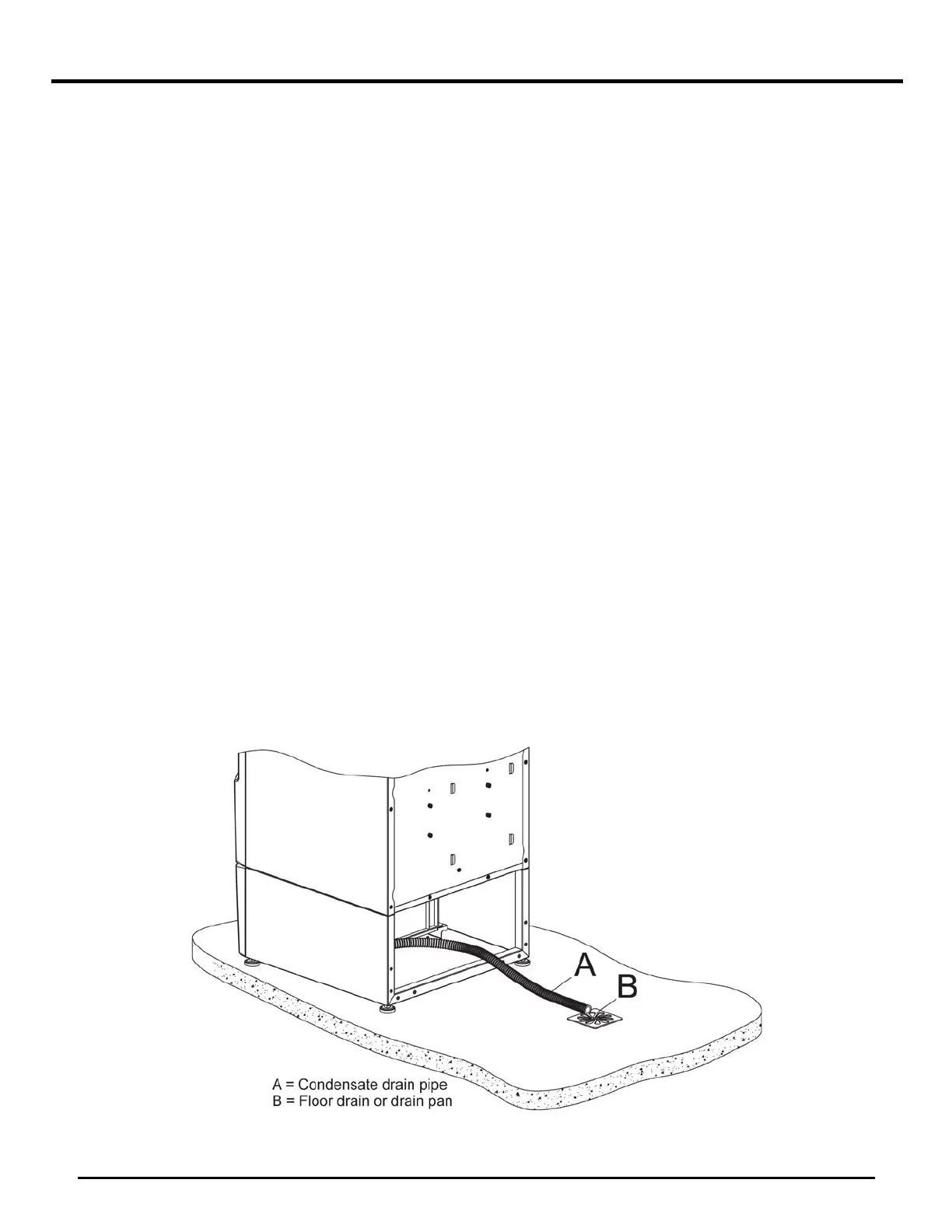

3.3. CONDENSATE DRAIN

To maintain proper flow of condensate the drain pipe must have a slope toward the drain of at least

3/8 in./ft. (30 mm/m). In order to prevent ice from forming, the condensate piping must be well

insulated.

Figure 9: Typical Condensate Drain Installation

Loading...

Loading...