MC2: 10/03/12 Page 40 of 90

AERCO International, Inc. • 100 Oritani Dr. • Blauvelt, NY 10913 • Ph: 800-526-0288

Modulex MLX Series Gas Fired Boiler System

Operation and Maintenance Manual

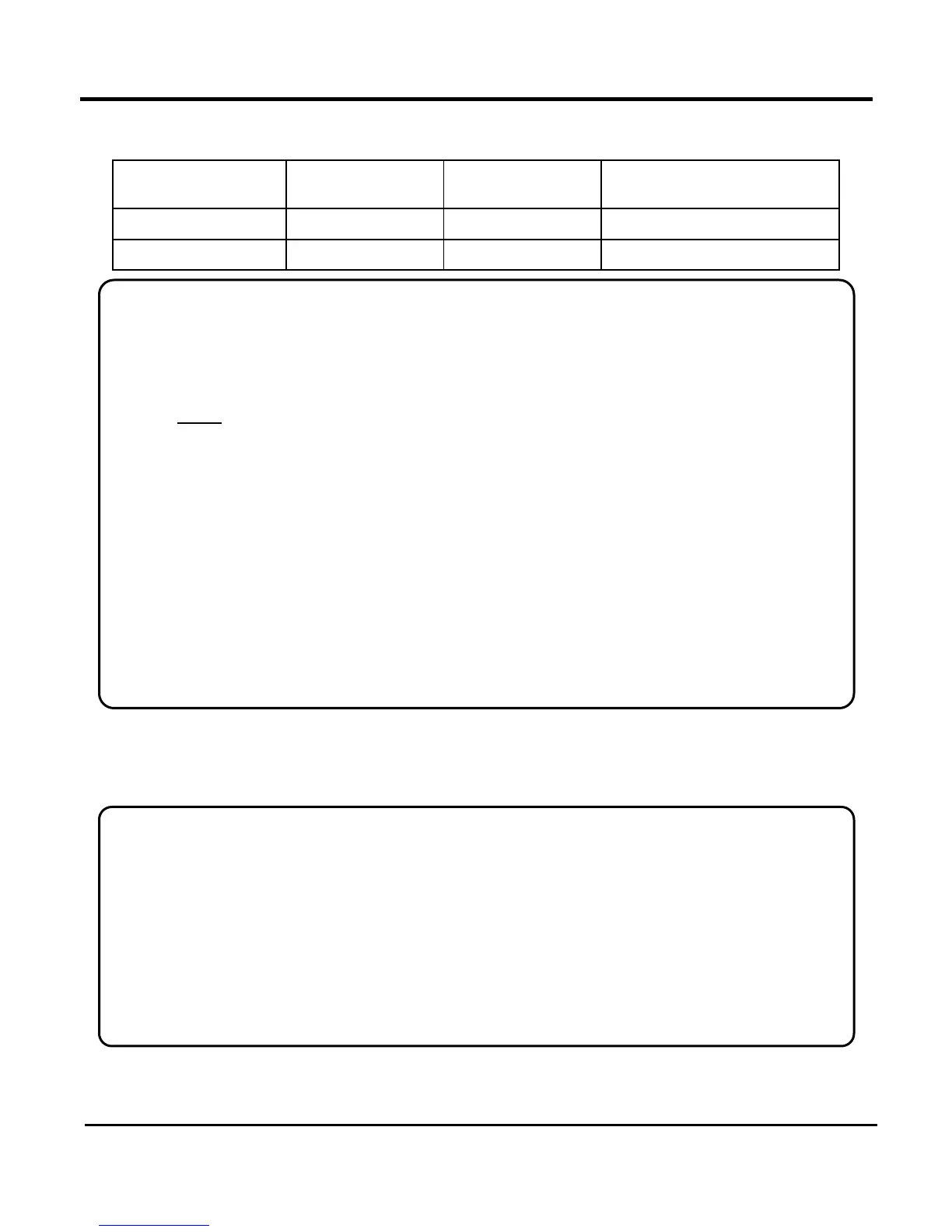

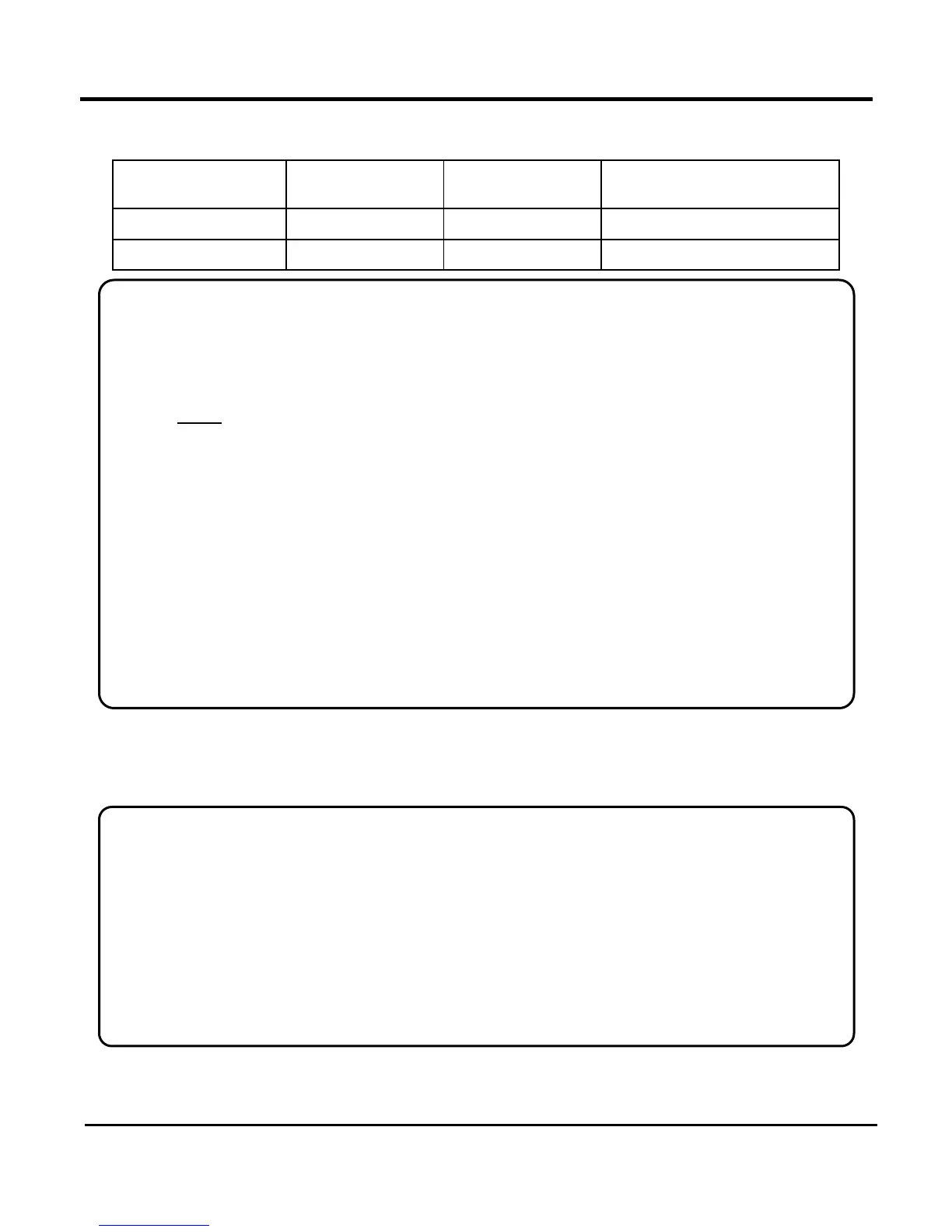

GAS SUPPLY OXYGEN (O

2

)

CARBON

DIOXIDE (CO

2

)

CARBON

MONOXIDE (CO)

NATURAL GAS 4.7% to 5.3% 9.1% to 8.8% <100 ppm

PROPANE 4.4% to 5.0% 10.7% to 10.4% <100 ppm

Combustion Calibration Procedure (Continued)

19. Verify that the oxygen (O

2

) level is within the range shown in Table 7-1 above. Also, ensure that the

carbon dioxide (CO

2

) and carbon monoxide (CO) are within the ranges shown.

20. If the oxygen level is not within the required tolerance, the gas valve for the boiler stage must be

adjusted. Remove the cap screw with a T40 Torx tool to access the Offset Adjustment Screw (Figure

7-3). Slowly rotate the Offset Adjustment Screw (in approximately 1/4 turn increments) in the desired

direction. Clockwise rotation reduces the oxygen level, while counterclockwise rotation increases the

oxygen level. Allow time for the combustion analyser to stabilize following each gas valve adjustment.

21. Once the oxygen level is within the required range for the first boiler stage, measure the gas pressure

at the outlet pressure tap. The pressure should be approximately 0.50” W.C. at the 10% fire rate.

22. Press the Program Key.

23. Using the Rotary Knob, set the displayed fire rate to zero (0). Press the Program key and wait until

the boiler stage turns off.

24. This completes the combustion calibration procedure for the first boiler stage.

25. Disconnect the manometer connected in step 3 and close the Outlet Pressure Tap by turning the

screw fully clockwise to its stop in preparation for the next boiler stage test.

On the controller, turn the Rotary Knob clockwise to the next Boiler stage. Repeat steps 16 through 25

for each remaining boiler stage (up to seven stages, depending on boiler size).

7.6 Unit Reassembly

Once the combustion calibration procedures have been completed for each boiler stage, the unit can

be reassembled for service operation per the instructions below.

Unit Reassembly

1. If it is still attached, remove the manometer from the gas valve outlet pressure tap. Close the tap by

rotating the screw fully clockwise to its stop.

2. Set the ON/OFF switch on the front of the Modulex boiler to the OFF position.

3. Turn off the gas supply to the boiler by closing the external shut-off valve.

4. Disconnect AC power.

5. Cover the hole drilled in the PVC flue pipe with foil tape.

Replace the top and side panels on the Modulex Boiler.

Table 7-1: Acceptable Combustion Gas Ratios at Boiler Input

Loading...

Loading...