EN

11_11. 6755532_02

High efficient scroll on anti-vibration mounts, acti-

vated by a 2-pole electric motor with internal heat

protection. They are supplied, as standard, with an

electric heater resistance, powered automatically

when the unit stops as long as the unit is power on.

Made with copper pipes and aluminium louvered

fins blocked by mechanical expansion of the pipes,

equipped with protection grid.

Unit with heat plate, insulated externally

with closed cell material to reduce heat loss.

Positioned at compressor inlet to protect from

refrigerant return.

evaporator, depending on the heat load, in order to

Mechanical dehydrator filter realised in ceramics

and hygroscopic material, able to withhold impuri

-

ties and any traces of humidity present in the cool-

ing circuit.

Used to check the refrigerant gas load and any pres-

ence of humidity in the cooling circuit.

-

cycles.

Used to keep the refrigerant gas in the liquid state

when the machine accumulates it excessively during

functioning.

Made in hot galvanised sheet steel with suitable

thickness and painted with polyester powders able

electric fans are protected electrically by magnet-

metal grids, according to the IEC EN 60335-2-40

Standard.

Equipped with steel filtering mesh; prevents the

heat exchangers from clogging.

It checks that there is circulation of water.If

this is not the case, it blocks the unit

Set at 6 bar and the discharge conveyor, discharging

the excess pressure occurs in the event of abnormal

pressures

assembled on the upper part of the hydraulic sy-

stem; it releases any air bubbles that may be present

in the system.

Positioned above evaporator, it has the task of

controlling that there is water circulation.

Adversary, it blocks the unit.

Calibrated at 6 BAR and with piped discharger,

dischargers if abnormal pressure occurs.

mesh with holes that do not exceed one millimetre.

It is indispensable in order to prevent serious damage

to the plate exchanger.

With nitrogen pre-load membrane

pressure drops

In stainless steel, with a 100-litre capacity. In

order to reduce the thermal dispersion and

-

of a suitable thickness.

Allows discharge of water

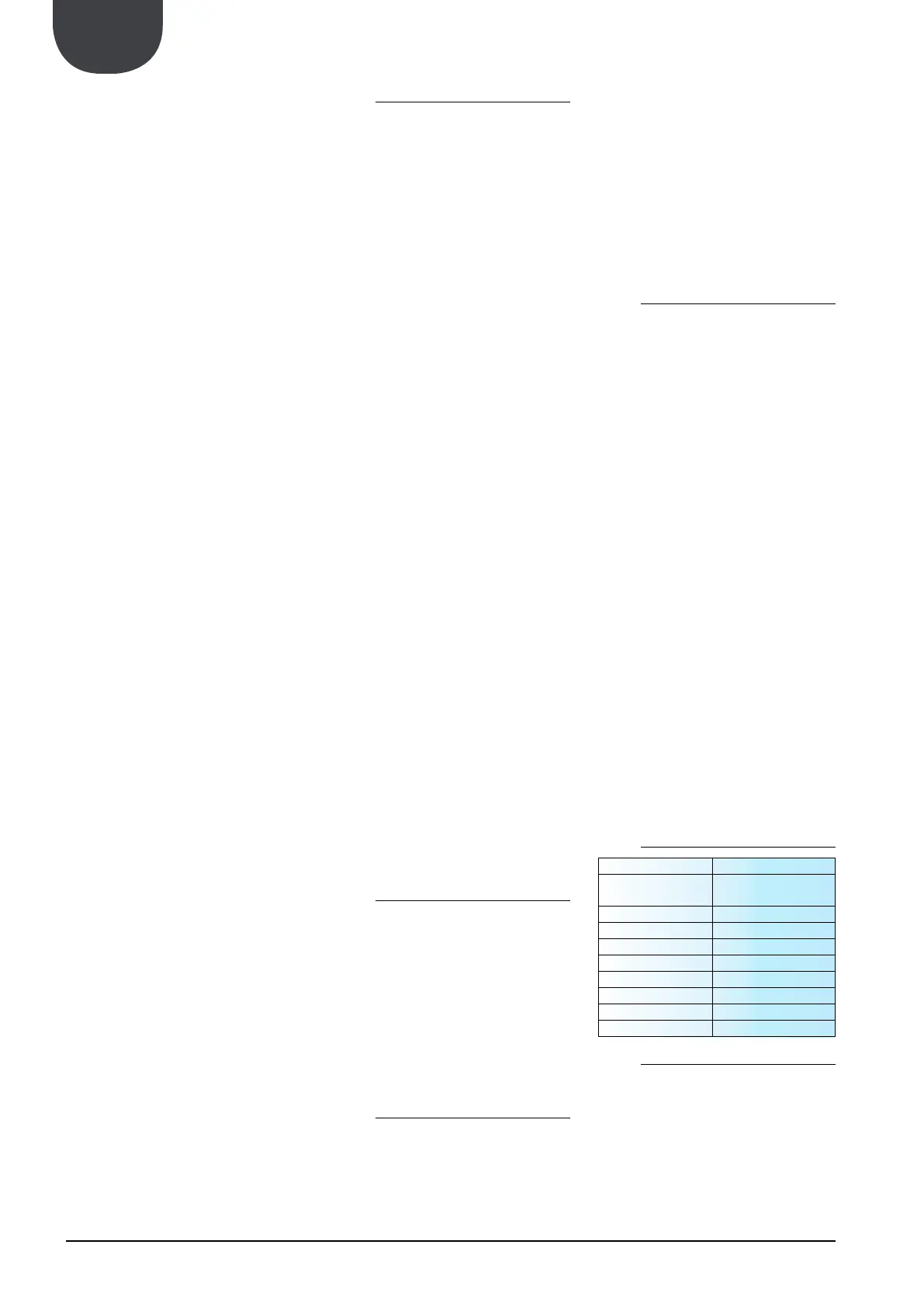

WATER FEATURES

PH 6-8

less than 200 mV/cm

less than 50 ppm

less than 50 ppm

less than 0.3 ppm

less than 50 ppm

less than 50 ppm

none

none

less than 30 ppm

With fixed calibration, placed on high pressure side

of cooling circuit, inhibits functioning of compressor

if abnormal work pressure occurs.

Placed on low pressure side of cooling circuit, signals

the work pressure to control board, generating a pre-

warning in case abnormal pressure occurs.

Loading...

Loading...