EN

11_11. 6755532_02

over device

connect the device contact to the

clamps 3 and 5 of the 13 POLE terminal board.

24.3.2.

To prepare an ON/OFF remote switch-over

device

connect the device contact to clamps 4 and 5

of the 13 POLE terminal board.

24.3.3.

If the necessity occurs to display the machine

block in a remote point

anomaly,

this is possible using

clamps 6 and 7 of

the 13 POLE terminal

board,

or visual alarm signal

device.

24.3.4.

To prepare a summer/winter switch-over

device, connect the device contact to clamps 8

and 9 of the 13 POLE terminal board.

24.3.5. CONTACT FOR THERMOSTATION

device, connect to clamps 10 and 11 of the 13

POLE terminal board.

24.3.6. CONTACT FOR BOILER CONTROL

To prepare a boiler control, connect to clamps

12 and 13 of the 13 POLE terminal board.

24.3.7.

If you should have the PR3 accessory, always

connect it to the 13 POLE terminal board as

shown below. Remember that the maximum

distance accepted is 150 mt. REMEMBER

THAT THE PR3 AS WELL AS BEING CONNECTED

Please note that, on request by the Aermec cus-

units in this series can be started up by the AERMEC

for the system. Prior to the work to be carried out by

the AERMEC service personnel, all other works (elec-

trical and hydraulic hook-ups, priming and bleeding

1.

2.

surface

3. The minimum technical spaces have been

respected;

4.

5. The hydraulic plant has been loaded and

bled.

6. The hydraulic circuit cocks are open

7.

correctly

8. The voltage is within the tolerance of 10% of

the unit nominal value

9. Earthing is correctly made. All electric

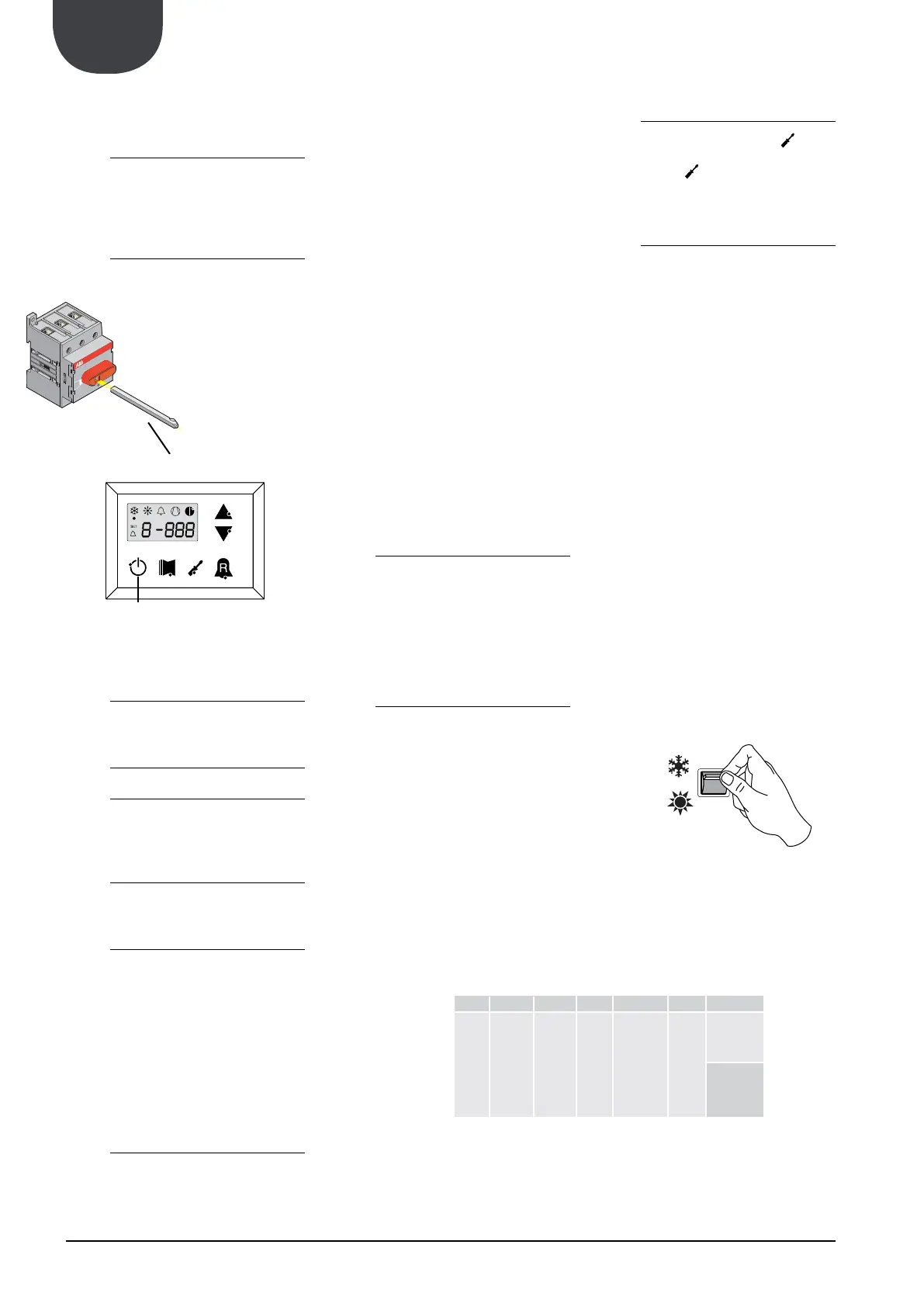

Close the electric control board hatch.

Press the ON key for 3 sec to switch the ma-

chine on.

- For every season change, check that the function-

ing limits lie within the limits.

- Check that the compressor input current is lower

than the maximum indicated in the technical data

table.

- Check, that in models with three-phase power

supply, that the compressor noise level is not

abnormal. If this is the case, invert a phase.

- Make sure that the voltage value lies within the

pre-fixed limits and that unbalance between the

above 3%.

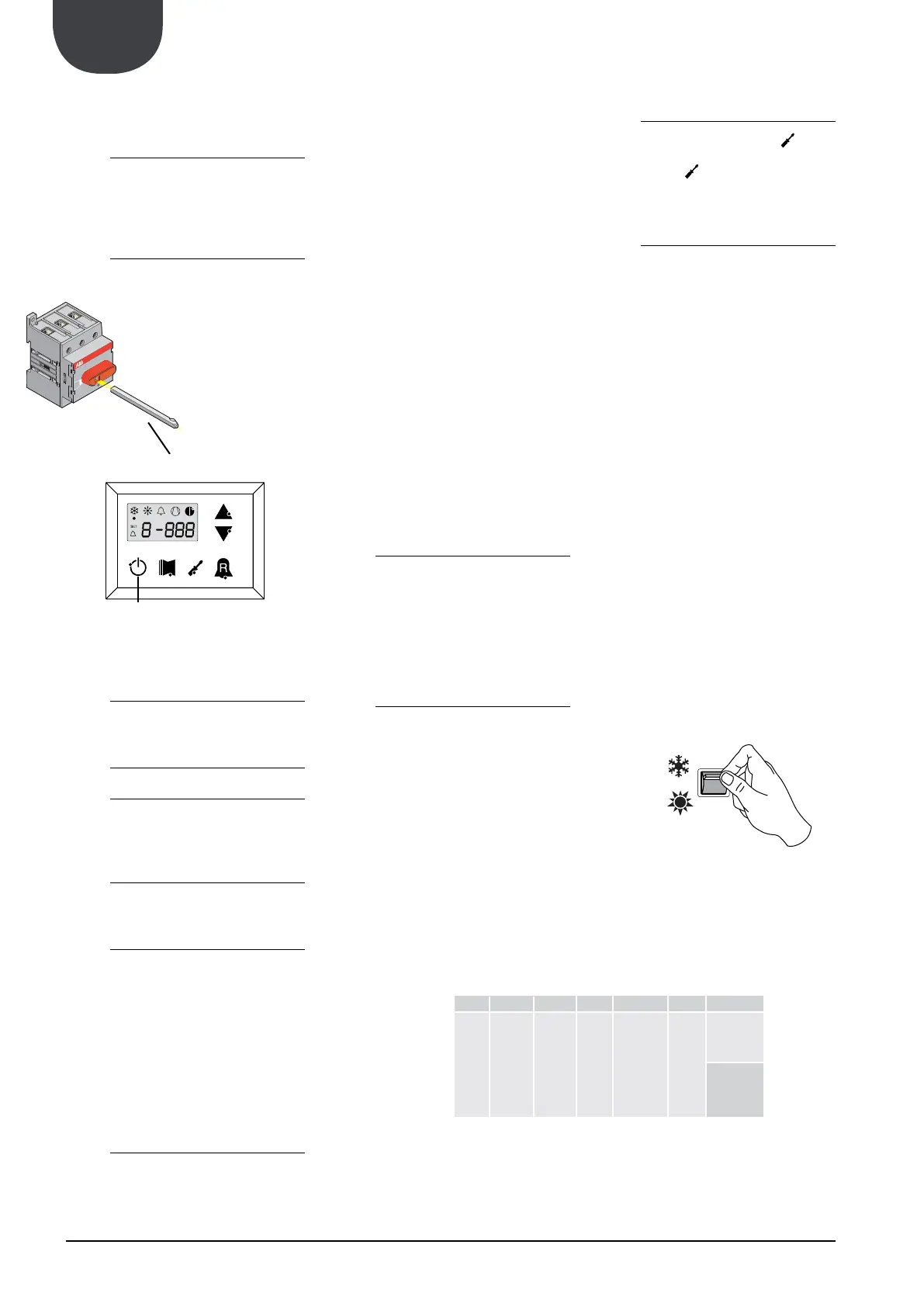

25.3.1. SEASON CHANGEOVER FROM PANEL ON

MACHINE

Access the USER SET list by touching the insert

password key 000 (already displayed; just confirm by

re-pressing the key .

The parameter affected is the 0.

For further information refer to the USER MANUAL

25.3.2. SEASON CHANGEOVER FROM PR3

Just act directly on the switch

and switches back-on with the selected

advance based on the

system. Prior to the work to be carried out by

the AERMEC service personnel, all other works

(electrical and hydraulic hook-ups, priming and

been completed.

ON/OFF

N CODE NAME

Sta Season

0 0 1

-

ing in cool-

ing mode

-

ing in heat-

ing mode

Loading...

Loading...