45

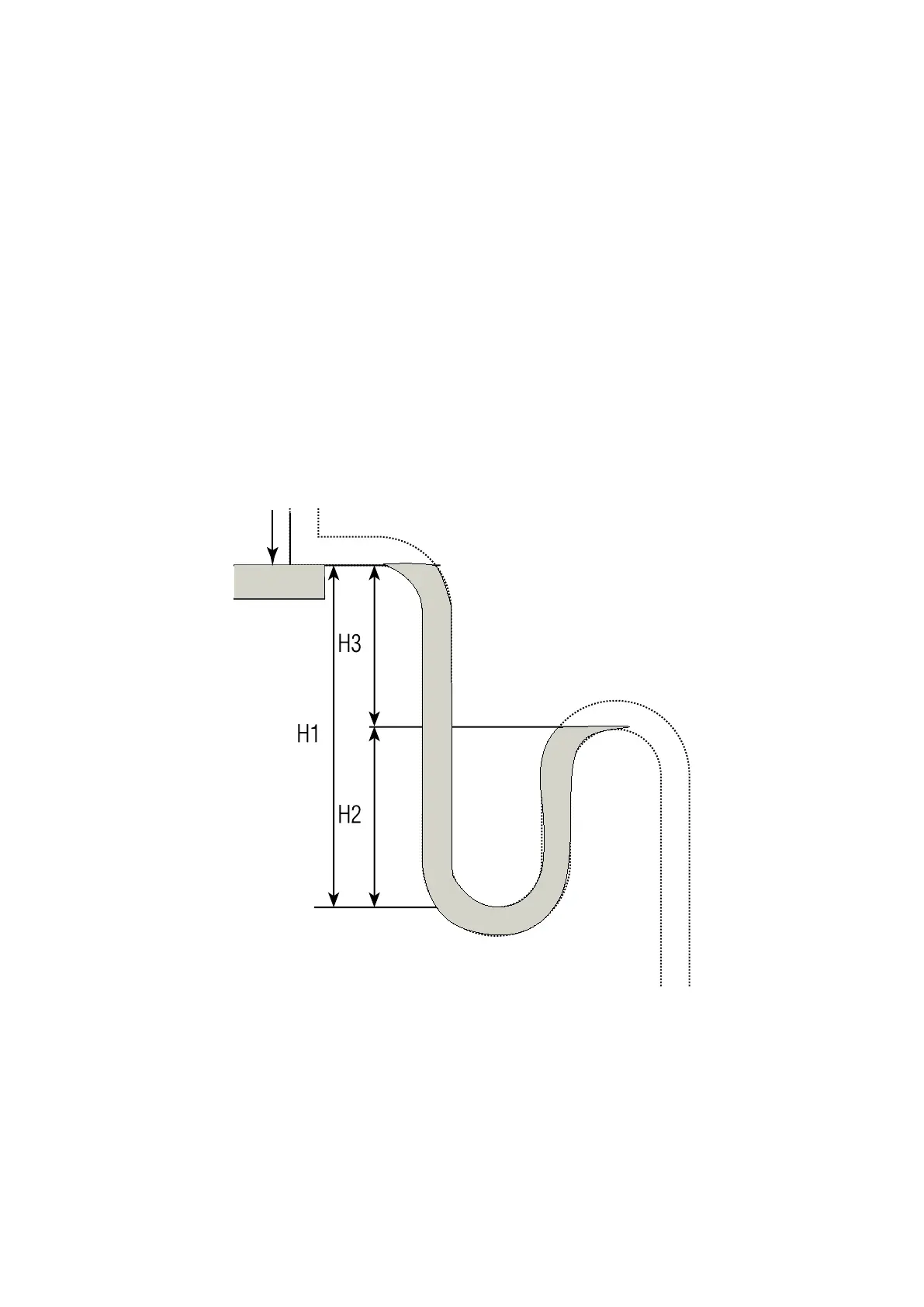

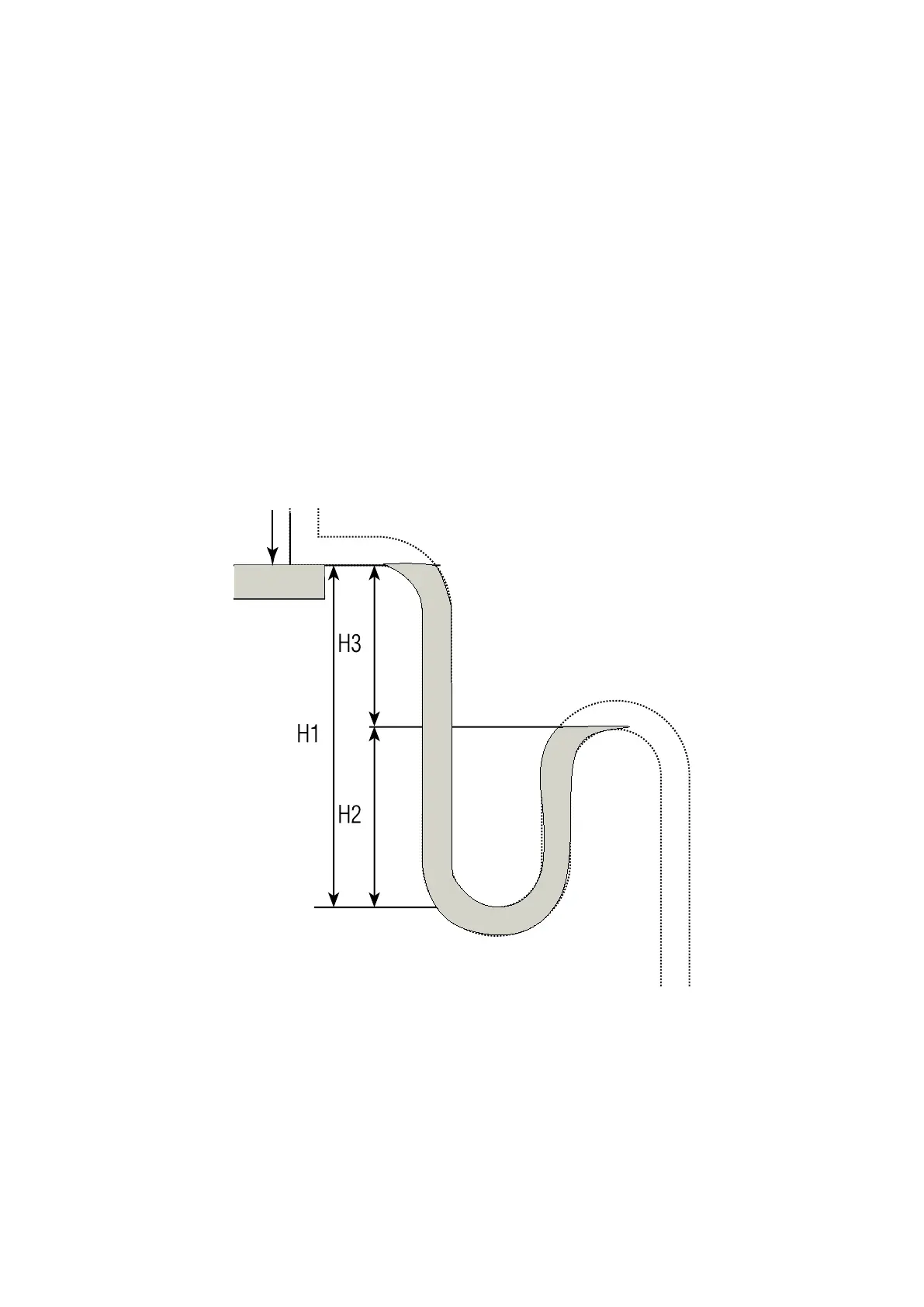

Siphon dimensioning layout

P

POS

CONNECTION INSTALLATION

AERAULIC CONNECTIONS

ATTENTION!

It is prohibited to start the machine if the fan vents are not ducted or

protected using an accident-prevention net.

To install the ducts, it is recommended to:

• prepare adequate bracketing to support the ducts so that the

recovery unit does not bear their weight;

• connect the ow and return vents to the ducts placing anti-

vibration joints in between (duck). The anti-vibration joint must be

screwed to the panel with self-threading screws avoiding that the

duck joints are taut during operation;

• provide an earth cable as a bridge on the anti-vibration joint to

guarantee equipotentiality between the ducks and the recovery

unit;

• prepare (before curves, branches, etc.) the ow duct with a straight

tract measuring at least 2.5 times the smallest side of the duct, A,

to prevent the ducting from having inclinations in the branching

tracts that exceed 7° so that the fan does not lose eciency.

Hydraulic connections: condensate draining

The condensate drip tray is equipped with a 1/2” -G UNI 338 threaded

outlet.

A drain system must envision a suitable siphon to:

• allow free draining of the condensate;

• prevent the undesired entry of air into the depression systems;

• prevent the inltration of smells or insects.

The siphon must have a bleed plug on the bottom or must however

allow quick disassembly for cleaning.

The following rules must be followed to dimension and execute the

siphon (see gure 21):

H1 = 2P

H2= H1 / 2

where P is the pressure expressed in mm of a column of water (1 mm c.w. =

9.81 Pa).

Loading...

Loading...