9

18.03. 5719210_03

ANL / 290-650

EN

5

10

1

4

4

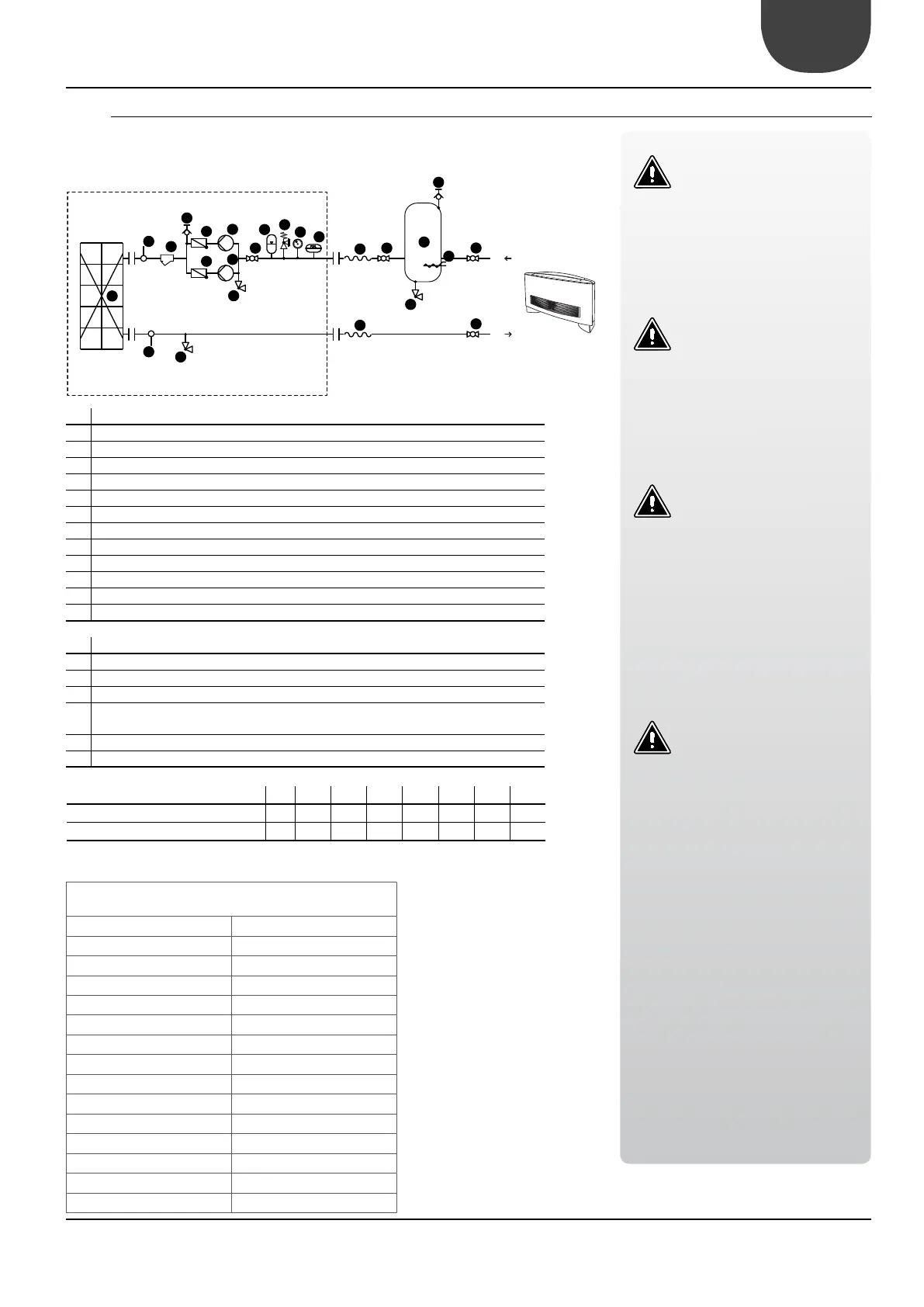

290 300 340 400 580 620 650

Numberofcompressors n° 2 2 2 2 2 2 2

Minimumrecommendedwatercontent l/kW 4 4 4 4 4 4 4

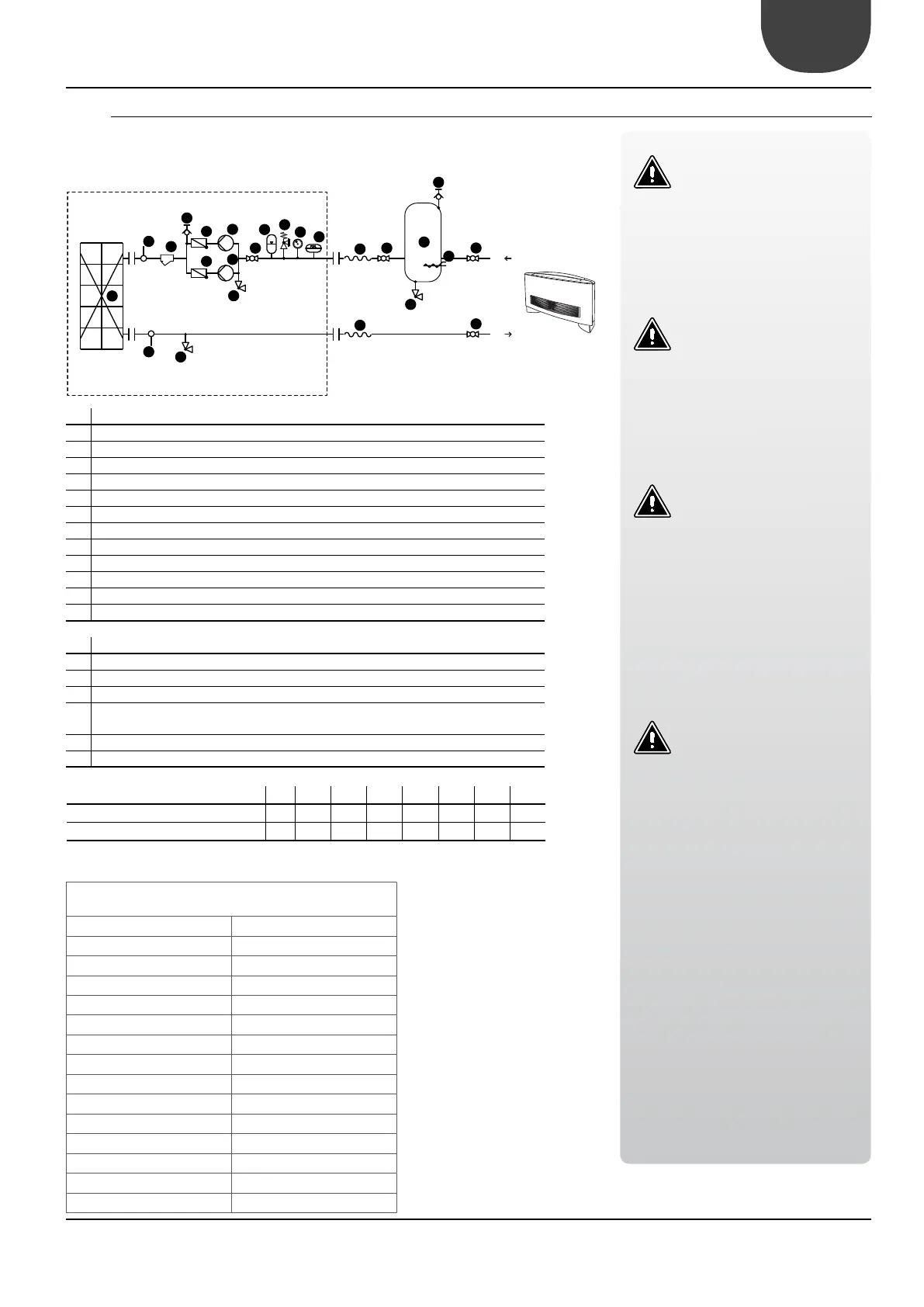

1. Plateheatexchanger

2. Waterfilter

3. Flowswitch

4. Airvent

5. Watertemperaturesensors(IN/OUT)

7. Isolatingvalve

8. Safetyvalve

9. Expansiontank

11. Gauge

12. Pump

14. Drainvalve

15. Non-returnvalve

4. Airvent

6. Anti-vibrationjoints

7. Isolatingvalve

10.

Systembuffertank(installationrecommendedifthetotalsystemwatercontentislessthanthat

indicatedinthetablebelow)

13. Electricanti-freezeheater

14. Drainvalve

WARNING

Theselectionandinstallation

ofcomponentsexternaltothe

unitaretheresponsibilityofthe

installerandmustbecarriedout

inaccordancewithgoodworking

practicesandapplicablestandards

ofthecountryofdestination.

WARNING

Thehydraulicpipingtotheunit

mustbeadequatelysizedforthe

requiredflowrate.Thewaterflow

ratethroughtheheatexchanger

mustalwaysbeconstant.

WARNING

Carefullycleanthesystempriorto

connectiontotheunit.Thisclean-

ingeliminatesweldingslag,dirt,

rustoranyotherimpuritiesfrom

thepiping.Theseimpuritiesmay

otherwisebedepositedwithin

theunitandcauseamalfunction

Theconnectingpipingmustbe

adequatelysupportedsoasnotto

imposeanyweightontotheunit.

WARNING

Duringthewinterperiodthewater

intheheatexchangermayfreeze

whenthesystemisoff,causing

irreversibledamagetotheheat

exchanger.

Therearethreesolutionstoavoid

theriskoffreezing

theunit.

2. Operatingwith

apercentageofglycolse-

lectedinaccordancewiththe

minimumanticipatedexternal

temperature.

.

Insuchcasestheelectricheat-

ersmustalwayshavepower

availableforthewholeperiod

ofpossiblefreezing(unitin

stand-by)

System: Chiller with plate heat exchanger

PH 7,5-9

Electric conductivity 100-500μS/cm

Total hardness 4,5-8,5 dH

Temperature < 65°C

Oxygen content < 0,1 ppm

Max. glycol amount 50%

Phosphates (PO4) < 2ppm

Manganese (Mn) < 0,05 ppm

Iron (Fe) < 0,3 ppm

Alkalinity (HCO3) 70 - 300 ppm

Chloride ions (Cl-) < 50 ppm

Sulphate ions (SO4) < 50 ppm

Sulphide ion (S) none

Ammonium ions (NH4) none

Silica (SiO2) < 30ppm

Loading...

Loading...