52 microAeth

®

MA Series MA200, MA300, MA350 Operating Manual microAeth

®

MA Series MA200, MA300, MA350 Operating Manual 53

AethLabsAethLabs

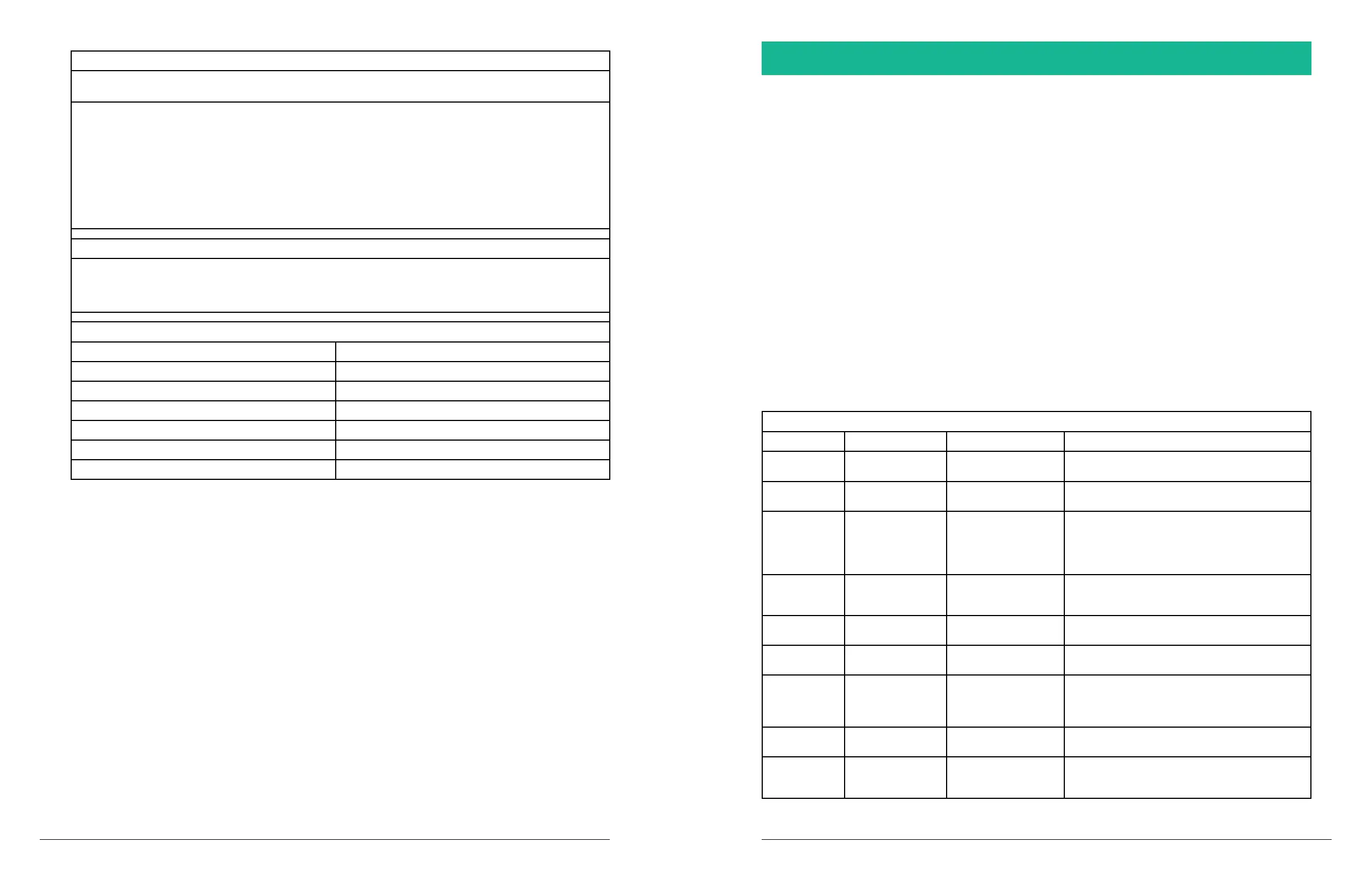

Example Response Message for AethLabs Implementation of Bayern-Hessen Protocol

The following hypothetical dataline (DualSpot) that might be available on the instrument at the time

the 'DA' command message is issued:

MA200-0011,25157,18,1,1.08,2018-12-06T20:29:01.00,-480,37.746172547,-122.

420371919,0.146,60,64,100,342,-611,

-24357,1,100.00,99.99,58.56,41.43,32.95,23.97,9.69,100596.00,33.62,DS-UV-B-G-R-IR,

681907,622183,917573,25.9730,18.4158,-0.0198,780829,620878,736176,19.5300,13.7320,

-0.0103,781964,625168,706936,16.6708,11.6571,0.0168,806763,690497,782392,13.4350,9.3264,

-0.0353,675814,773992,951767,9.4010,6.3921,

-0.1671,415,374,274,396,376,330,427,478,594,377,340,255,510,410,198,5D91

Expected response message:

MD07 001 +2740+02 00 00 011 000000 002 +3300+02 00 00 011 000000 003 +5940+02 00 00 011

000000 004 +2550+02 00 00 011 000000 005 +1980+02 00 00 011 000000 006 +1000+02 00 00 011

000000 007 +1000+00 00 00 011 000000

Expected response message values:

UV BCc 274

Blue BCc 330

Green BCc 594

Red BCc 255

IR BCc 198

FlowTotal 100

Tape Position 1

5.10. Filter Media

The sample collection and analysis is performed on a roll of polytetrauoroethylene (PTFE) lter tape that is

housed in the lter tape cartridge. As the aerosol sample is drawn through the lter media by the instrument’s

integrated, internal sample pump, the aerosol sample collects gradually on the lter medium to create a

gray spot 3mm in diameter. The microAeth determines the optical attenuation as the accumulated particles

increase the optical density of the lter spot. After the optical density reaches a certain level, which is set by

the ATN Tape Trigger setting, the lter spot must be replaced to maintain measurement integrity. The lter

tape roll is automatically advanced to provide a new clean spot location for sampling. IMPORTANT: Do not

rewind the lter tape cartridge, or use previously sampled lter tape sampling locations.

The tape position counter counts each time the lter tape cartridge advances. This counter is reset every time

the tape clamp mechanism is released and then reclamped. The instrument does not specically know the

position of the lter tape in the lter tape cartridge in relation to the beginning or end of a lter tape cartridge.

The user is responsible for keeping track of this process using the counter as a guide. The instrument is able

to know and notify the user when a lter tape cartridge has reached the end of the tape.

5.11. Data Safety

AethLabs highly recommends keeping a prestine backup of the original data collected on the instrument in an

exported le.

6. Viewing and Analyzing Measurement Data

6.1. Data File Structure

The data les exported through the microAeth Manager are plain text with the extension .csv. Each data

le consists of a header containing descriptive information; a line identifying the data columns; and then a

number of data lines with each item separated by a comma. As the microAeth is starting a new sampling and

measurement session, the rst few minutes of data do not contain the BC calculation; all subsequent lines of

data show this value except during an automatic tape advance.

Exported Data File Structure:

Serial number, Datum ID, Session ID, Data format version, Firmware version, App version, Date / time local,

Timezone offset (mins), Date local (yyyy/MM/dd), Time local (hh:mm:ss), GPS lat (ddmm.mmmmm), GPS long

(dddmm.mmmmm), GPS speed (km/h), GPS sat count, Timebase (s), Status, Battery remaining (%), Accel

X, Accel Y, Accel Z, Tape position, Flow setpoint (mL/min), Flow total (mL/min), Flow1 (mL/min), Flow2 (mL/

min), Sample temp (C), Sample RH (%), Sample dewpoint (C), Internal pressure (Pa), Internal temp (C), Optical

cong, UV Sen1, UV Sen2, UV Ref, UV ATN1, UV ATN2, UV K, Blue Sen1, Blue Sen2, Blue Ref, Blue ATN1,

Blue ATN2, Blue K, Green Sen1, Green Sen2, Green Ref, Green ATN1, Green ATN2, Green K, Red Sen1, Red

Sen2, Red Ref, Red ATN1, Red ATN2, Red K, IR Sen1, IR Sen2, IR Ref, IR ATN1, IR ATN2, IR K, UV BC1, UV

BC2, UV BCc, Blue BC1, Blue BC2, Blue BCc, Green BC1, Green BC2, Green BCc, Red BC1, Red BC2, Red

BCc, IR BC1, IR BC2, IR BCc

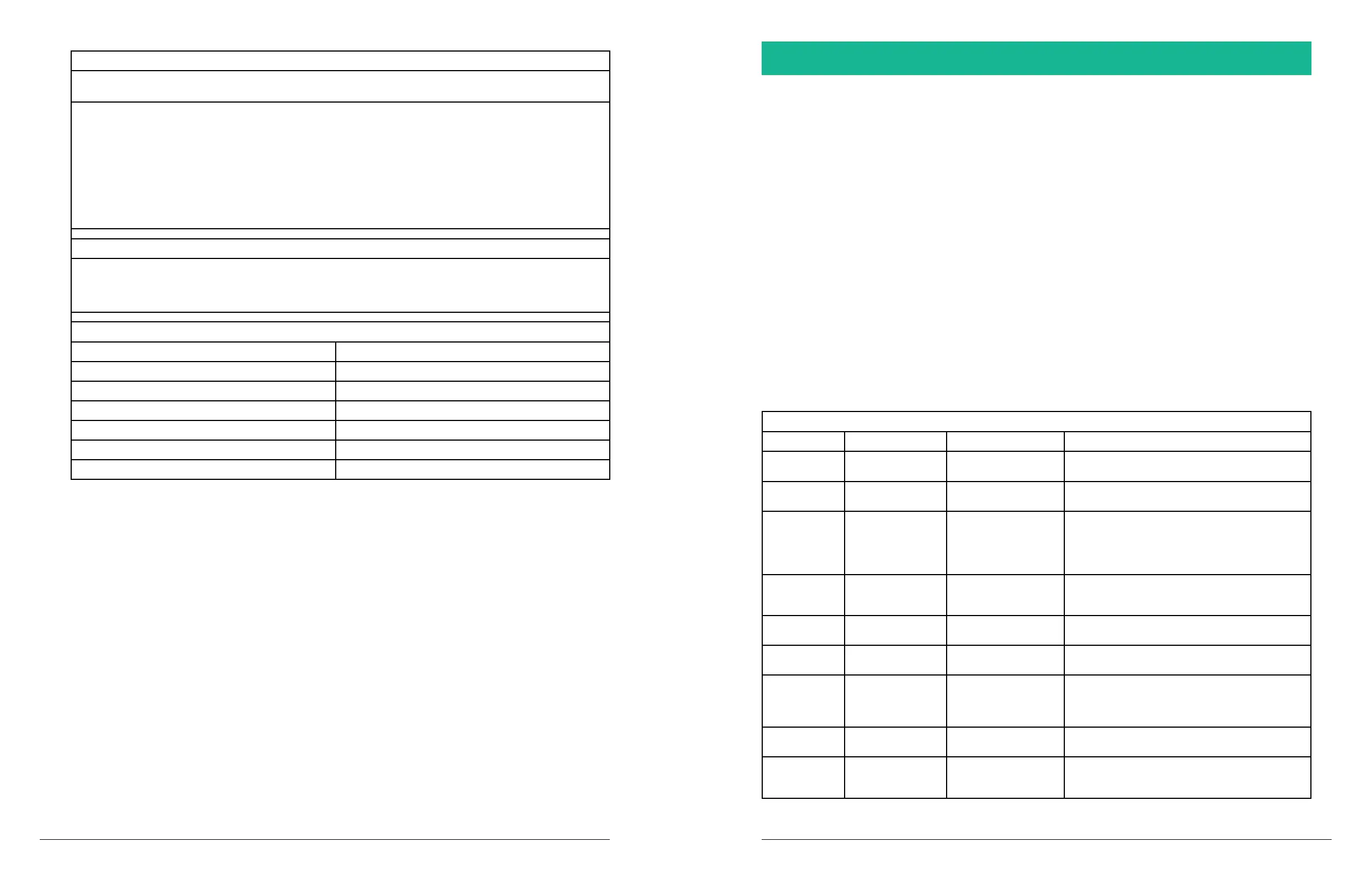

Exported Data File Structure Details

Header Units / Format Example Data Description

Serial number

Model and number

(MAxxx-xxxx)

MA200-0001 Unique identication number for the Instrument.

Datum ID Whole number 1

Identication number assigned to each line of

recorded data.

Session ID Whole number 1

Identication number assigned to each sampling

and measurement session. This value is incremented

each time a new sampling and measurement

session is started (changes from STOPPED to

SAMPLING mode).

Data format

version

Natural number 1

Unique identication number for exported data le

structure used when exporting data from microAeth

Manager software.

Firmware

version

Decimal number 1.08

Unique identication number for rmware running on

instrument when measurement was recorded.

App version Decimal number 1.03

Unique identication number for microAeth Manager

software that was used to export data le.

Date / time local

Year, month, day,

hours, minutes,

seconds (yyyy-MM-

ddTxx:xx:xx)

2018-03-21T14:17:00

Local date and time calculated from instrument's

internal clock using Coordinated Universal Time

(UTC) and Timezone offset.

Timezone offset

(mins)

Minutes (Integer) -420

Timezone offset from Coordinated Universal Time

(UTC) in minutes.

Date local

(yyyy/MM/dd)

Year, month, day

(yyyy/MM/dd)

2018/03/21

Local date calculated from instrument's internal

clock using Coordinated Universal Time (UTC) and

Timezone offset.

Loading...

Loading...