64 microAeth

®

MA Series MA200, MA300, MA350 Operating Manual microAeth

®

MA Series MA200, MA300, MA350 Operating Manual 65

AethLabsAethLabs

6.2.2. Minimal Structure

SingleSpot™ sampling mode:

Preamble, Date / Time GMT, Timezone offset, Status, Battery, Tape position, Flow total, UV BC, IR BC,

CKSUM

DualSpot® sampling mode:

Preamble, Date / Time GMT, Timezone offset, Status, Battery, Tape position, Flow total, Flow1, Flow2, UV

BC1, UV BC2, IR BC1, IR BC2, CKSUM

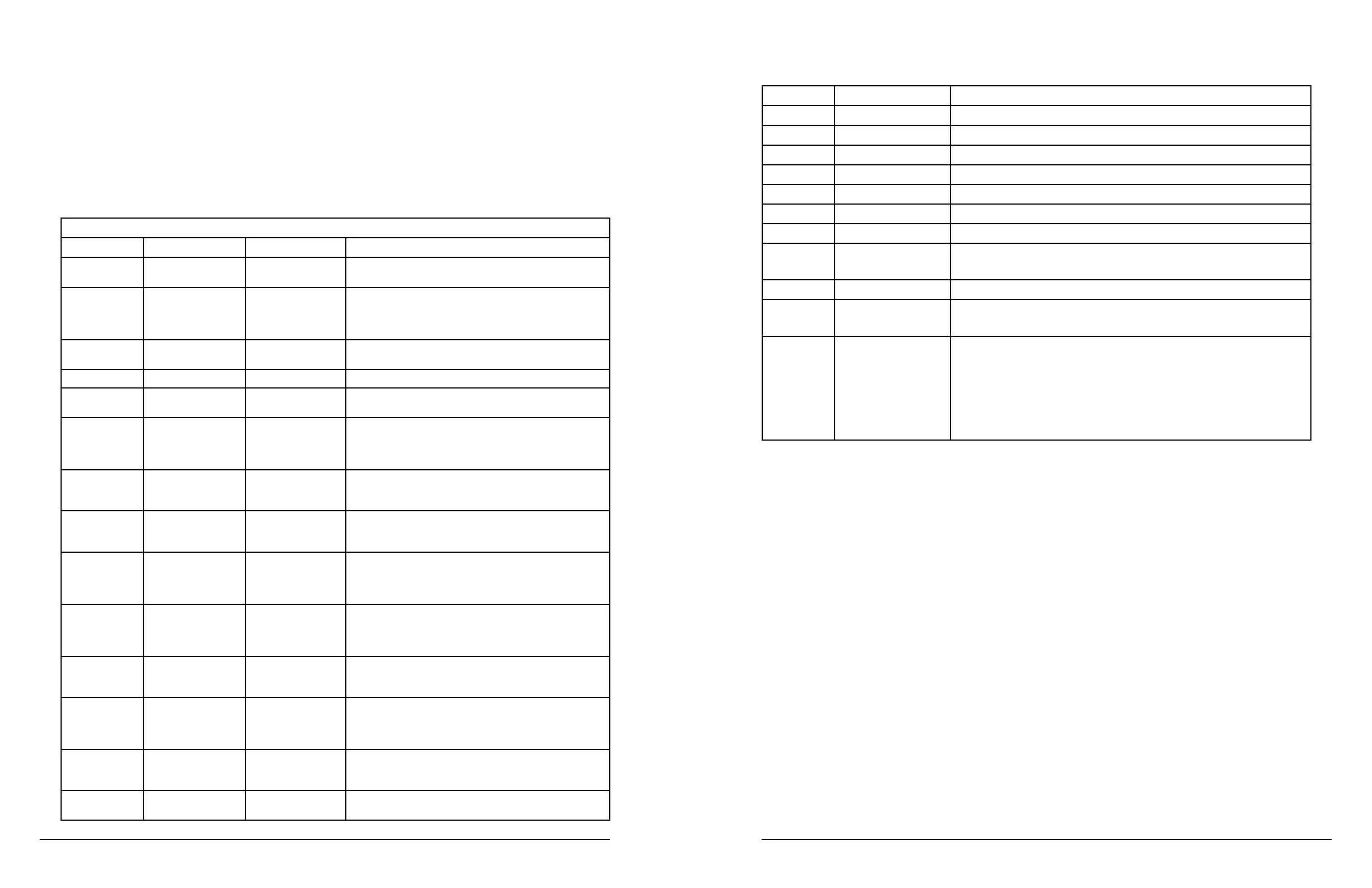

Minimal Structure Details

Header Units / Format Example Data Description

Preamble

Alphanumeric

(XXXXXX)

55AAFF Identication for serial data stream format.

Date / Time

GMT

Year, month, day,

hours, minutes,

seconds (yyyy-MM-

ddTxx:xx:xx.xx)

2018-03-

21T14:17:00.00

Local date and time produced from instrument's internal

clock using Coordinated Universal Time (UTC).

Timezone offset Minutes (Integer) -420

Timezone offset from Coordinated Universal Time (UTC)

in minutes.

Status Whole number 1 See section 6.3. Status Codes for detailed information.

Battery

Percent

(Whole number)

88 Percent of instrument internal battery remaining.

Tape position Whole number 1

Value of tape position counter. Increments by 1 after

each tape advance. Counter is reset when 'Release

Tape' is used to release the tape cartridge no matter the

position of the newly inserted tape cartridge.

Flow total Milliliters per minute

(Decimal number)

100.10

Measured total ow through the instrument in milliliters

per minute. Measured in SingleSpot™ and DualSpot®

sampling modes.

Flow1

Milliliters per minute

(Decimal number)

60.23

Measured ow through sample spot sense1 of the

instrument in milliliters per minute. Measured in

SingleSpot™ and DualSpot® sampling modes.

Flow2

Milliliters per minute

(Decimal number)

39.87

Calculated ow through sample spot sense2 of the

instrument in milliliters per minute. Calculated in

DualSpot® sampling mode. No ow in SingleSpot™

sampling mode.

UV BC1

Nanograms per

cubic meter (ng/m

3

)

(Integer)

23201

Calculated mass concentration for ultraviolet (UV)

wavelength for sample spot sense1 in nanograms per

cubic meter. Calculated in SingleSpot™ and DualSpot®

sampling modes.

UV BC2

Nanograms per

cubic meter (ng/m

3

)

(Integer)

24101

Calculated mass concentration for ultraviolet (UV)

wavelength for sample spot sense2 in nanograms per

cubic meter. Calculated in DualSpot® sampling mode.

IR BC1

Nanograms per

cubic meter (ng/m

3

)

(Integer)

23958

Calculated mass concentration for infrared (IR)

wavelength for sample spot sense1 in nanograms per

cubic meter. Calculated in SingleSpot™ and DualSpot®

sampling modes.

IR BC2

Nanograms per

cubic meter (ng/m

3

)

(Integer)

23745

Calculated mass concentration for infrared (IR)

wavelength for sample spot sense2 in nanograms per

cubic meter. Calculated in DualSpot® sampling mode.

CKSUM

Alphanumeric

(XXX)

D39

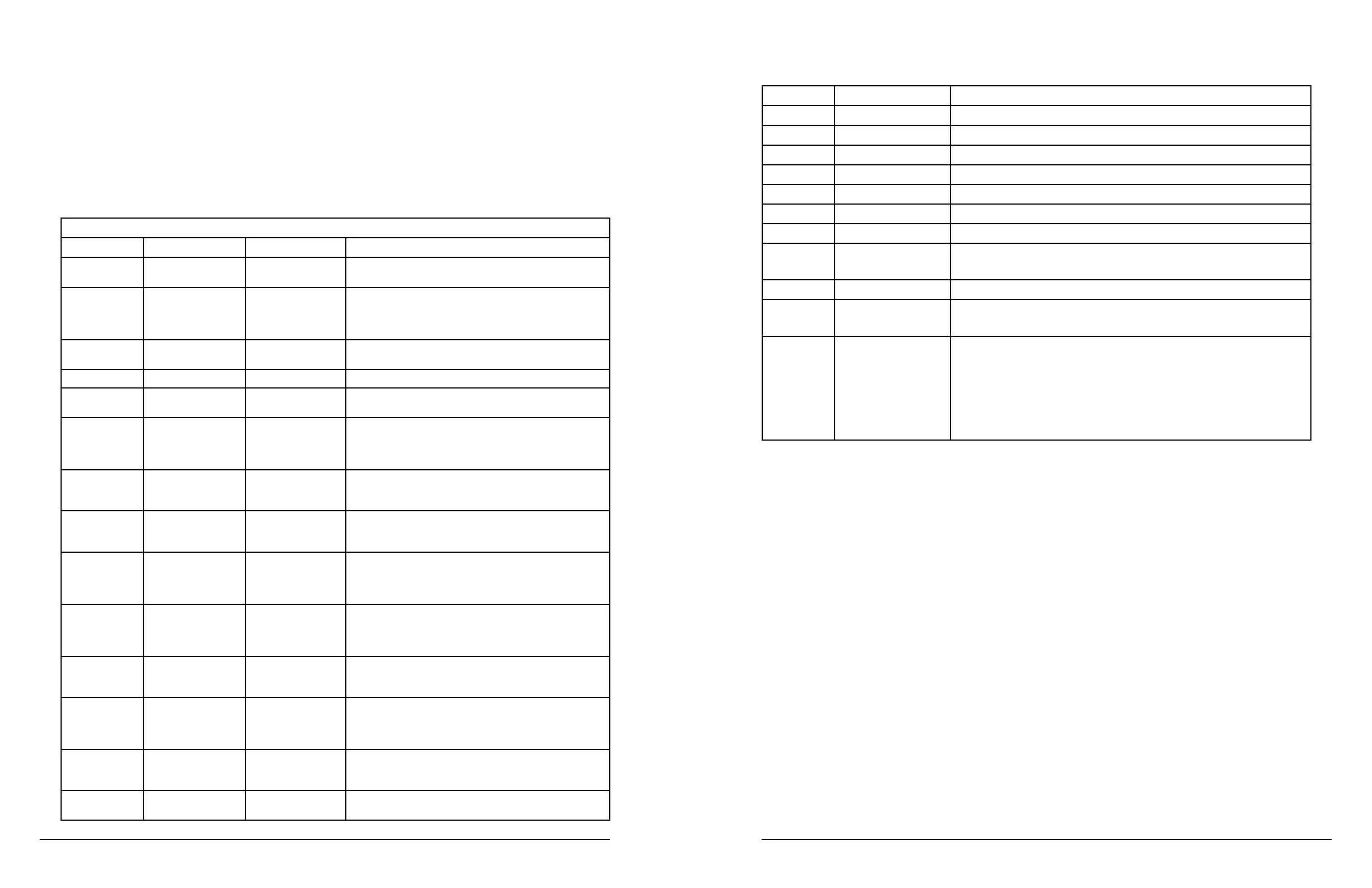

6.3. Status Codes

Code Value Readable status Status Description

1 No status notications

2 Start up Instrument in sampling and measurement startup

4 Tape advance Tape advance occurring during sampling and measurement period

8 N/A

16 Optical saturation Optical saturation

32 Sample timing error Sample timing error

64

Sampling spot 2 of DualSpot

®

loading compensation is active

128 Flow unstable

Flow unstable during sampling and measurement period. Flow

deviates from target ow setpoint by more than ±5%.

256 Pump drive limit Flow out of range during sampling and measurement period

512 Time source manual

Time synchronization source is manual (synchronized to application/

computer time or no GPS time is available)

1024

User skipped tape

advance

User skipped tape advance. No tape advance occurred at start of

sampling and measurements.

NOT RECOMMENDED!

SKIPPING THE AUTOMATIC TAPE ADVANCE AT THE BEGINNING

OF SAMPLING AND MEASUREMENTS SHOULD ONLY BE USED

WHEN GOOD DATA QUALITY IS NOT NEEDED.

If more than one status code is active simultaneously, the resulting code written to the data le is the sum of

the error codes shown in the table above. For example, if the instrument is starting up (status code = 2) and

the sampling spot 2 of DualSpot

®

loading compensation is active (status code = 64), the status code shown

in the data le will be 66.

Loading...

Loading...