79034308 B Rev. 02-9

General Information

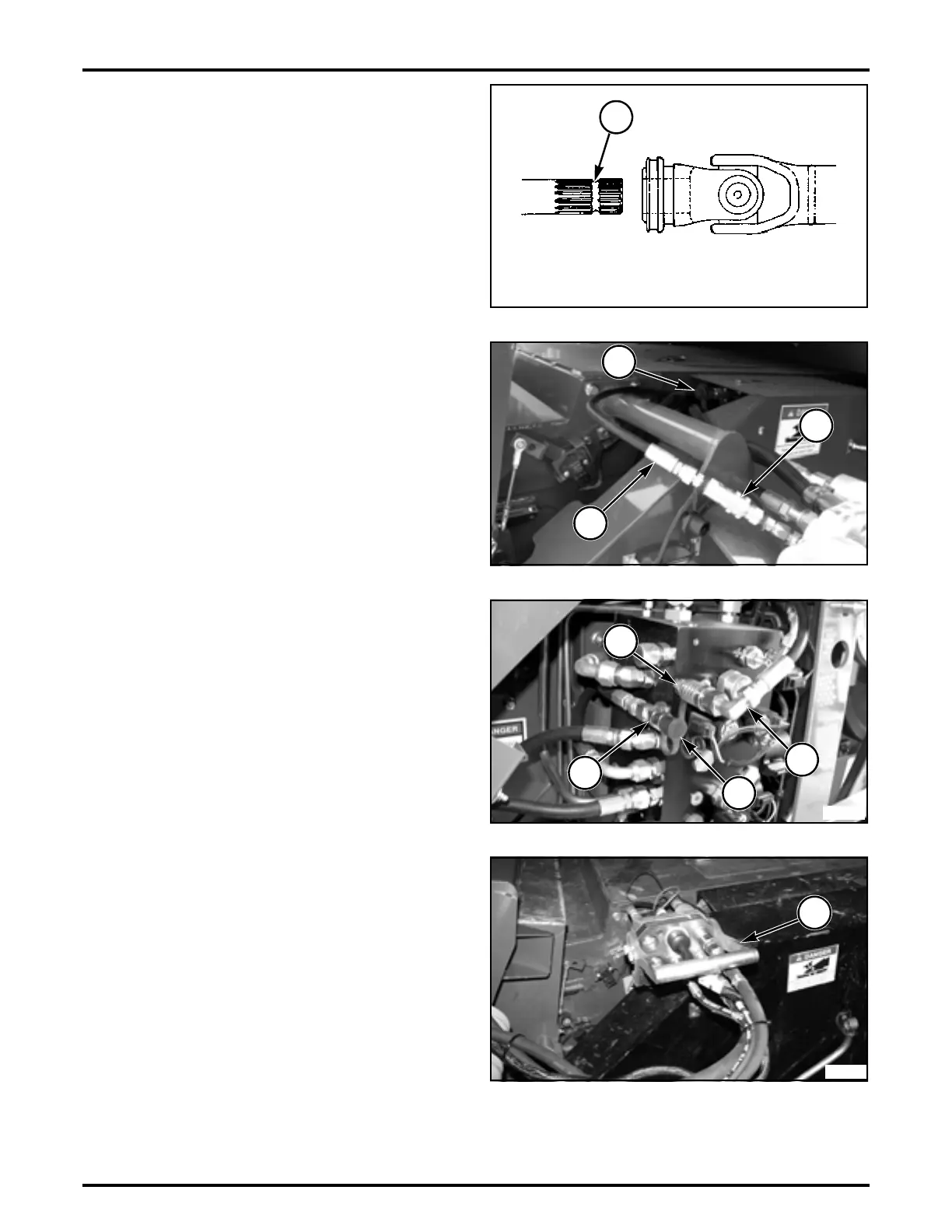

FIG. 19: Release the locking ring and pull back and forth

on the driveline to make sure that the coupling is locked in

the annular groove (1) on the countershaft.

Repeat the procedure for the opposite driveline on dual

knife drive.

IMPORTANT: Be sure that the same letter is showing in

the indicator windows on the PTO bells after the

installation of the left and the right drivelines.

FIG. 20: Transverse Machine - If a corn head has

been attached, install the reel lift hose (1) onto the reel lift

fitting (2) on the single point connector. Make sure the

dust cap (3) is installed on the variable speed fitting.

Move the lockout ring on the variable speed drive sheave,

on the left-hand side of the pivot shafts to the locked

position.

IMPORTANT: When running the grain head, the variable

speed header drive must be locked in the

slowest position. Over speeding will damage the

grain header.

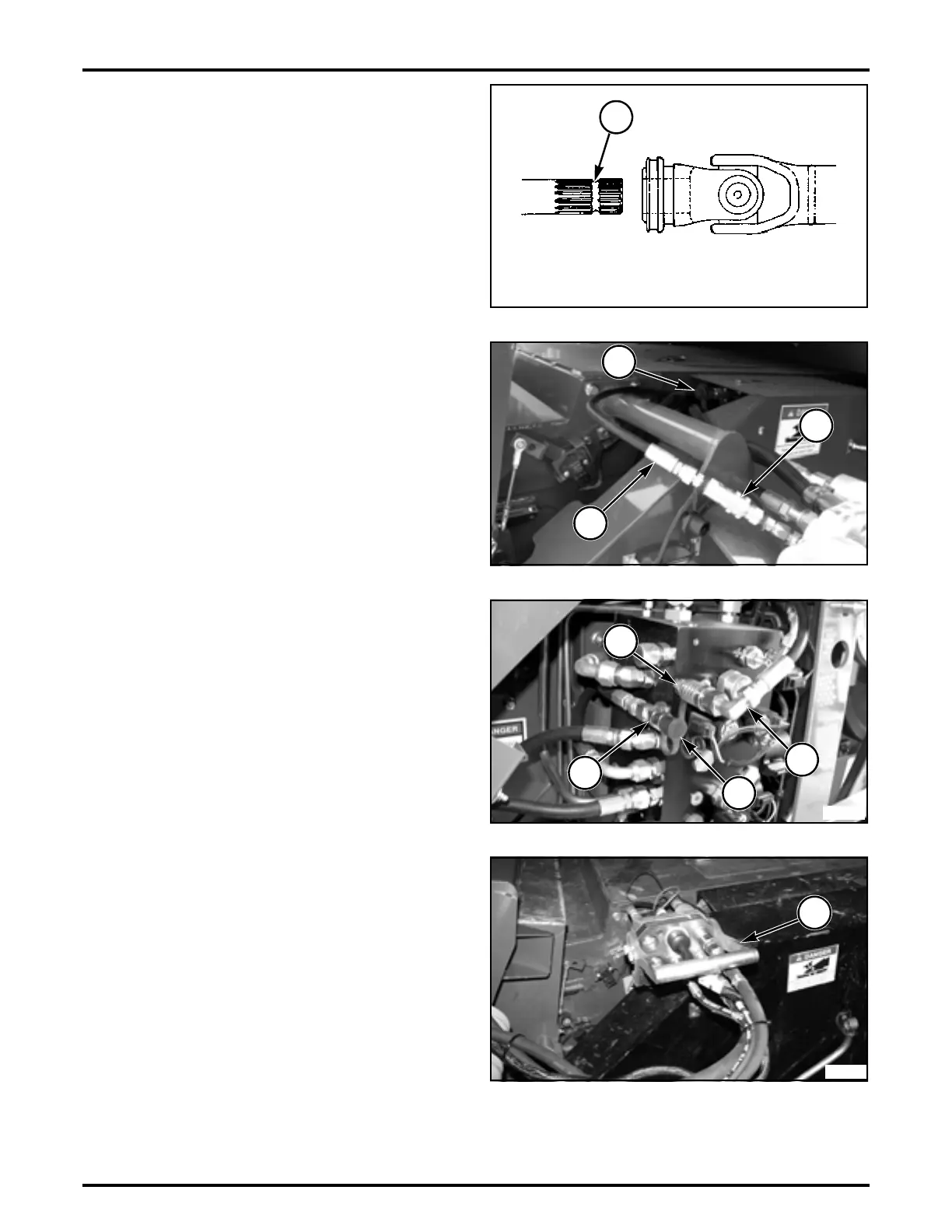

FIG. 21: Axial Machine - If a corn head has been

attached, install the variable speed hose (1) onto the male

coupling fitting (2) in the main hydraulic control valve.

Make sure the dust cap (3) is installed on the variable

speed fitting (4) at the reel lift port.

Move the lockout ring on the variable speed drive sheave,

on the right-hand side of the pivot shaft, to the locked

position.

IMPORTANT: When running the grain head, the variable

speed header drive must be locked in the

slowest position. Over speeding will damage the

grain header.

FIG. 22: Connect the mobile single point connector (1) to

the single point connector on the machine. Align the

connectors and close the over-center latch locking the

connectors together.

NOTE: To install the header on a machine without a

single point connector, and adapter is needed.

Refer to the appropriate sections to set the proper cutter

bar tilt for the drive tires used on the machine, level of the

header, set the auger flighting clearance, draper pressure,

and reel lift cylinder phasing.

m

WARNING: DO NOT operate the machine

unless ALL shields are installed.

FIG. 19

FIG. 20

FIG. 21

FIG. 22

Loading...

Loading...