Maintenance and Repair

46

Meadow mower agria 5300

Municipal cutter bar

Switch off the engine

Pull off the sparking-plug connector

Wear protective gloves

Removing the mower knife

• Using the lever provided, lift the

rocker arm off the driver pins (4) and

swing it sideways outside the knife

• Pull out the cutter bar from the

front

• Clean the cutter bar and lightly

lubricate it with organic lubricating

oil

Put down the mower knives only

when they are in the knife protection bar

Installing the mower knives

• The assembly is carried out in re-

verse order

Maintenance

• Lubricate the lubricating nipple (11)

with organic grease after each mow-

ing and/or after the cutter bar has

been cleaned with a water spray,

but at least after every 8 operating

hours.

• With new rocker arm guides, addi-

tionally lubricate once after approx.

1 hour of operation

• After each knife change and after

every 8 hours of operation, apply

some organic grease to the driver

pins (4) of the mower knife

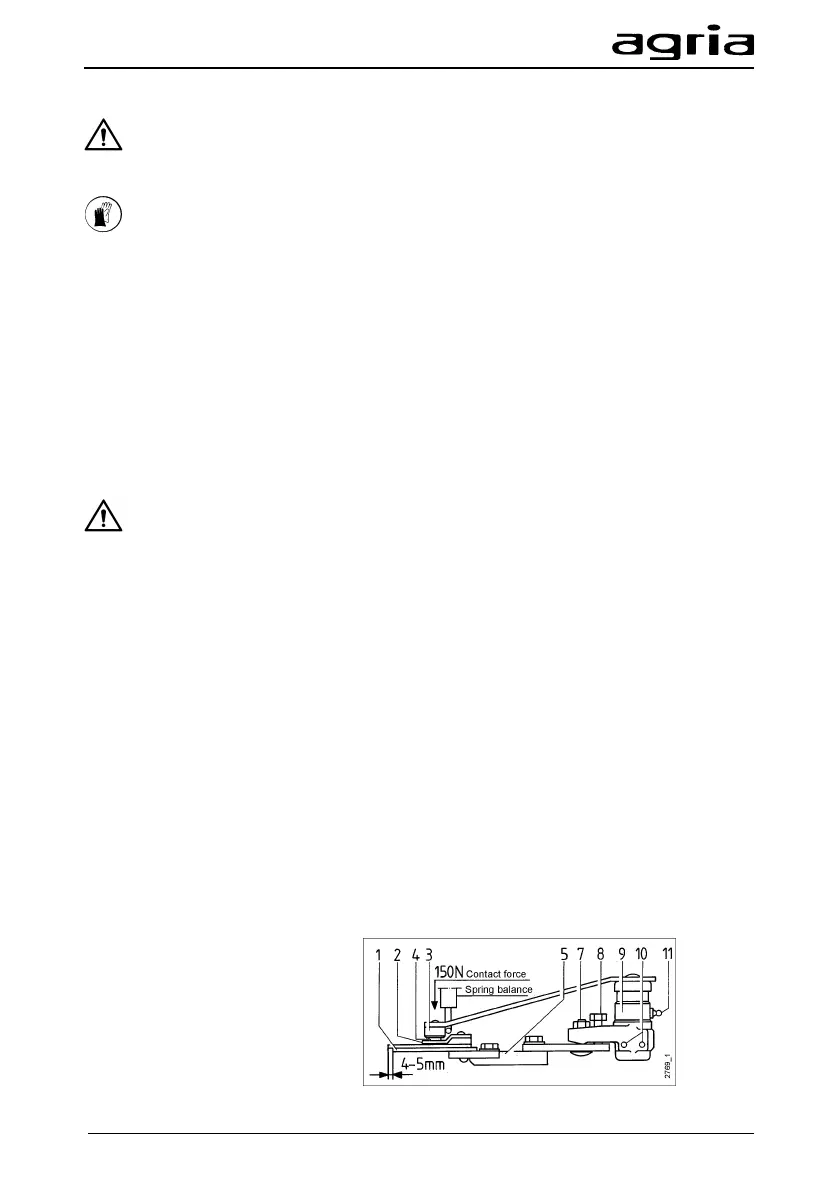

Adjusting the knife guide

• After every 25 operating hours, check the contact pressure of the rocker arms

(approx. 150 N) with a commercially available spring balance

• To increase or readjust the contact pressure of the rocker arms:

- Slightly loosen the 2 fixing screws (7) of the bearing bodies

- Actuate the adjusting screws (8) to adjust to the correct contact pressure of

about 150 N. Subsequently, tighten the 2 fixing screws (7).

- Whenever you loosen the screws (7), make sure that the bearing body (9) is

at right angles to the back of the beam (5)

- Also make sure that the projection of the knife blade tips in relation to the

beam knives is about 4 ... 5 mm in the centre position

• The driver sleeve (3) and/or the driver pin (4) must be replaced if the play be-

tween these two parts is larger than 2 mm or if the driver sleeve (3) comes into

contact with the pin carrier (2)

• When fitting new clamping sleeves (10), make sure that the slots always point

to the outside!

ixing screw

Loading...

Loading...