9-8 EB AT-RP-4GU EN

Service

Fig. 9-12

15

16

40

05

Fig. 9-13

01

Fig. 9-14

40

40

50

40° - 45°

− With pistons completely closed (0° position) as per Fig.

9-15, referring to the axis of the body, the rotation ob-

tained must be:

– about over 0° up to 5°, for models AT051U to

AT801U

– strictly about over 0° up to 0.5° for model AT045U.

− With pistons completely closed (0° position) as per Fig.

9-15 the dimension “A“ must be the same on both sides

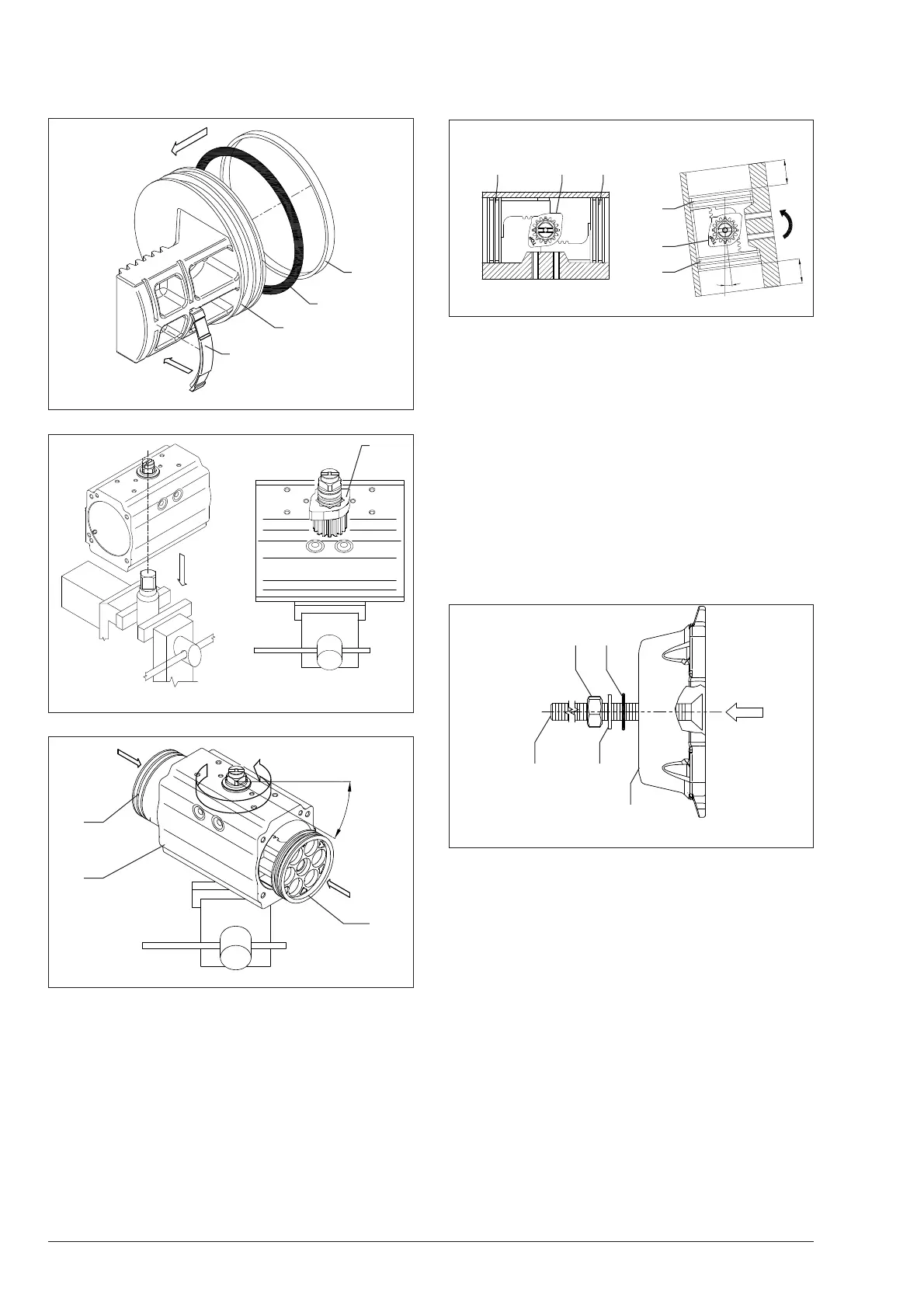

Fig. 9-15

90° position 0° position

01 4040

40

40

01

5°

A

A

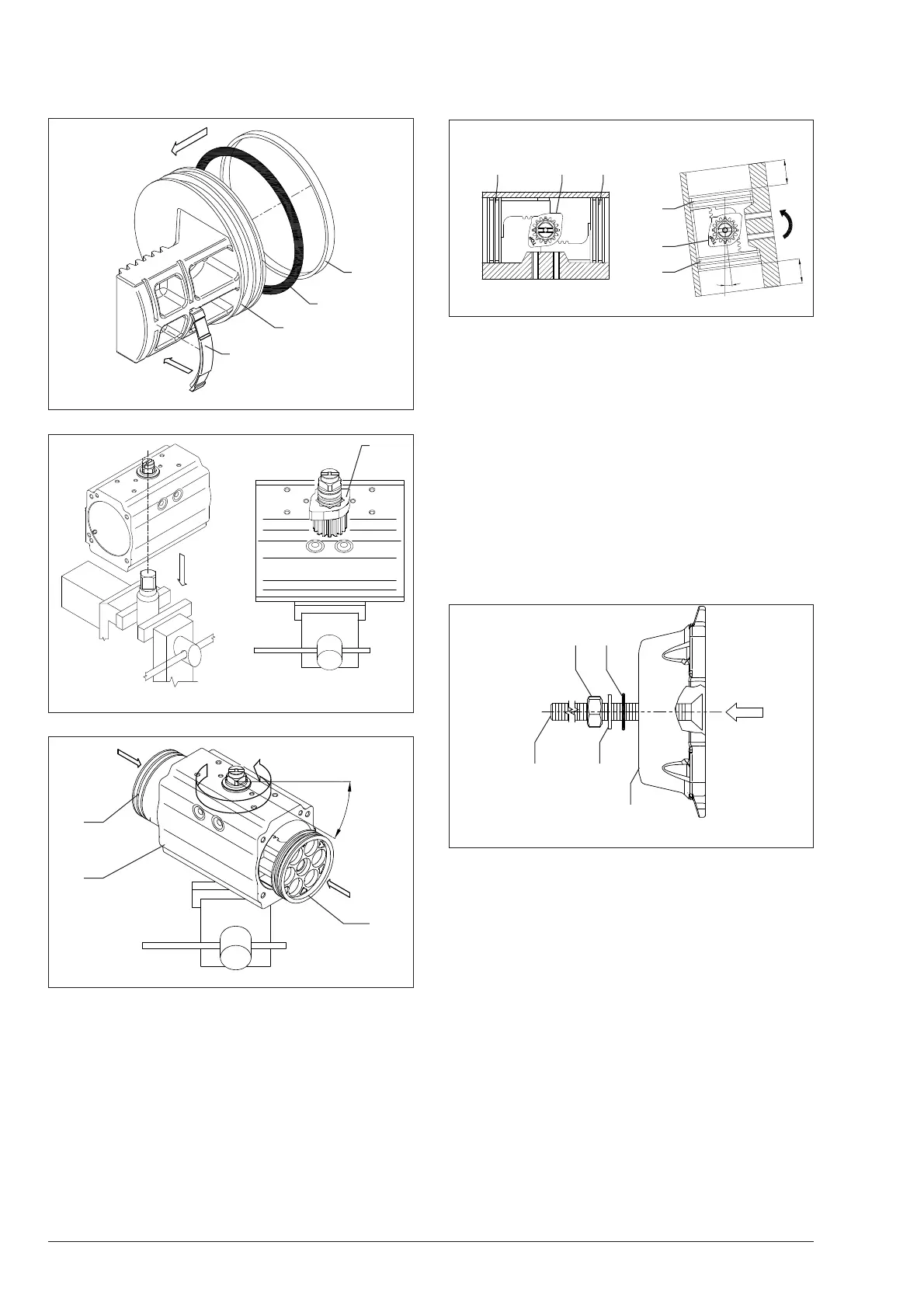

9.5.3 End caps reassembly

Assemble one end cap (30/30R) at a time.

− In case of actuator with extra travel stop adjustment:

– fasten the stop screws (221G/222G) into the end caps

(30) aligning the head of the screw to the end cap sur-

face as shown in Fig. 9-16.

– lubricate and place the o-rings (11R),

– place the washer (03R) and fasten partially the nuts

(04R).

Î Refer to the data sheet [T.D.S. 2.1.5.1.1] for extra travel

stop adjustment components.

Fig. 9-16

11R04R

221G

222G

03R

30R

− Place the end caps o-ring (14) into the groove as shown in

Fig. 9-17 making sure that the o-ring is stable in its

housing.

− Lubricate again the internal surface of the body (50).

− Place the actuator in vertical position.

− In case of spring return actuator, place the correct quantity

of spring cartridges in the correct position as indicated in

Table 9-4, Table 9-5, Fig. 9-18 and Fig. 9-19 depending

on the actuator model.

Loading...

Loading...