EB AT-RP-4GU EN 9-9

Service

Fig. 9-17

14

30

30R

Table 9-4

SPRING TYPE FOR MODELS AT045U

Spring set Side B Side A

S1-1 1 (green) 1 (green)

S1-2 1 (green) 2 (red)

S2-2 2 (red) 2 (red)

S2-3 2 (red) 3 (black)

S3-3 3 (black) 3 (black)

Table 9-5

SPRING TYPE FOR MODELS AT051U

Spring set Side B Side A

Internal External Internal External

S1 1 (green) / / 2 (black)

S2 / 2 (black) / 2 (black)

S3 / 2 (black) / 3 (red)

S4 / 3 (red) / 3 (red)

S5 / 3 (red) 1 (green) 2 (black)

S6 1 (green) 2 (black) 1 (green) 2 (black)

S7 1 (green) 2 (black) 1 (green) 3 (red)

S8 1 (green) 3 (red) 1 (green) 3 (red)

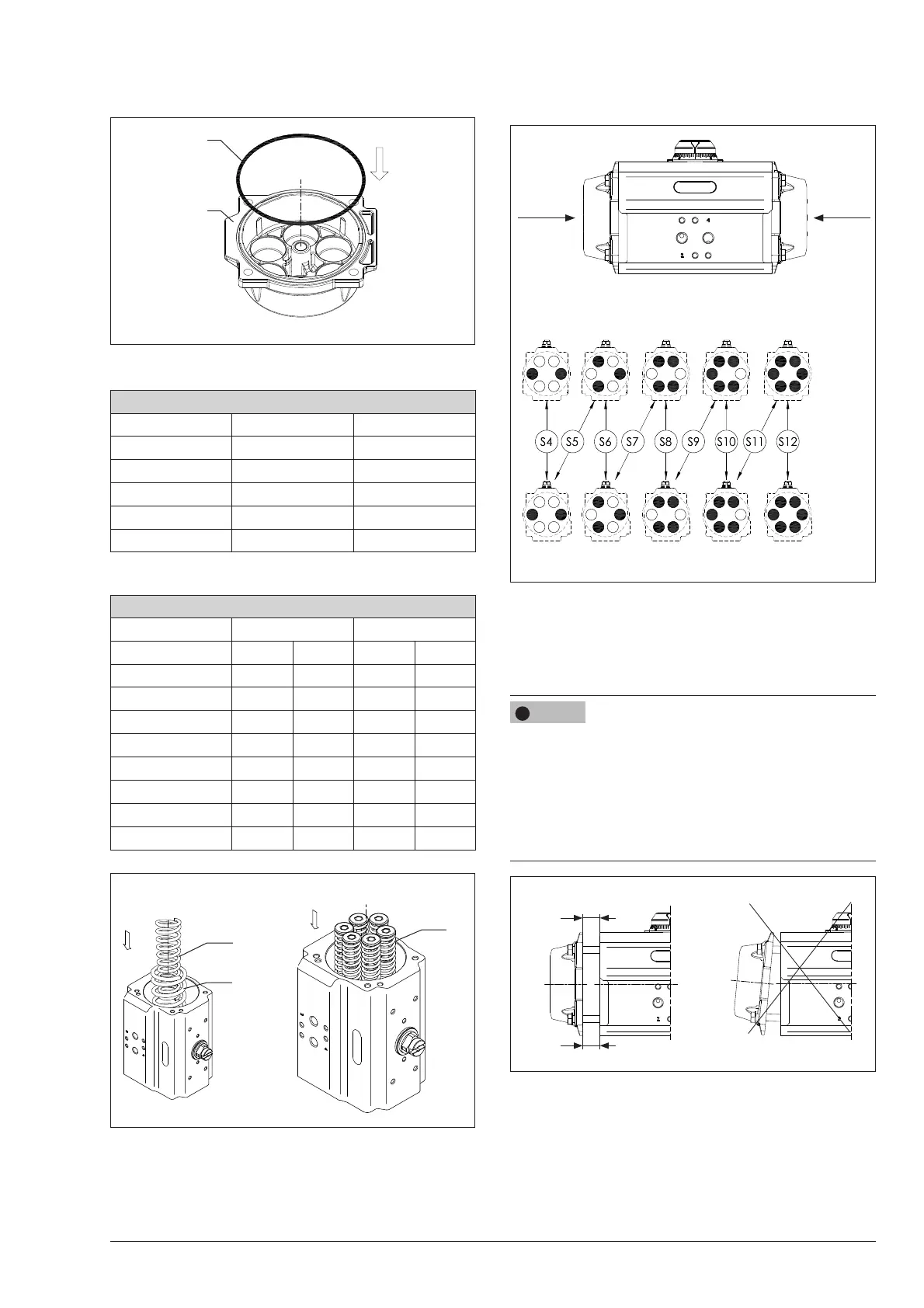

Fig. 9-18

17

17.3

17.1

17.2

AT045U and AT051U from AT101U to AT801U

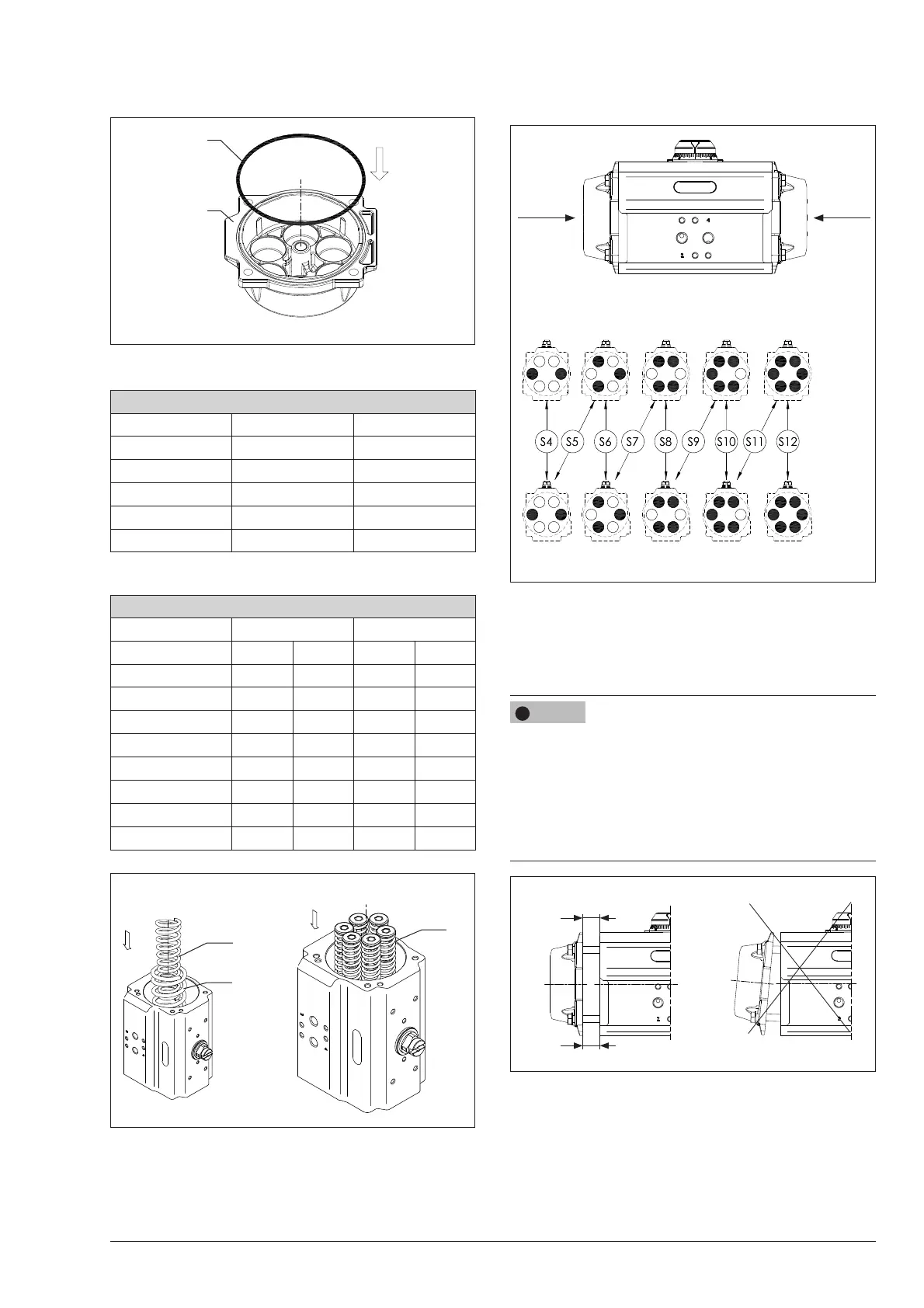

Fig. 9-19

Side A

Side A

Side B

Side B

models AT101U to AT801U

− Place the end cap (30/30R).

− Fix the end cap (30/30R) fastening partially the cap

screws (13) 1 turn at a time following the sequence indi-

cated in Fig 9-21.

Risk of components damage due to incorrect assembly.

During reassembling the end caps can be damaged due to

uneven force generated by compressed springs.

Î Assemble the end caps as shown in Fig. 9-20 keeping a

constant distance (A = B) between the actuator body and

the end cap interface.

Î Observe the specied sequence shown in Fig. 9-21.

Fig. 9-20

B

A

A = B

− Complete the fastening of the cap screws (13) tightening 1

turn at a time for each screw in th sequence shown in Fig.

9-21.

Î Refer to the section 15.2 ‘Tightening torques‘. (Table 15.1)

NOTICE

!

Loading...

Loading...