9-10 EB AT-RP-4GU EN

Service

Fig. 9-21

3

2

4

1

1

2

5

3

4

6

1

7

2

5

3 8

4

6

TOTAL QUANTITY OF

CAP SCREWS (13)

PER ACTUATOR:

− 8

− 12

− 16

SEQUENCE OF

ASSEMBLY:

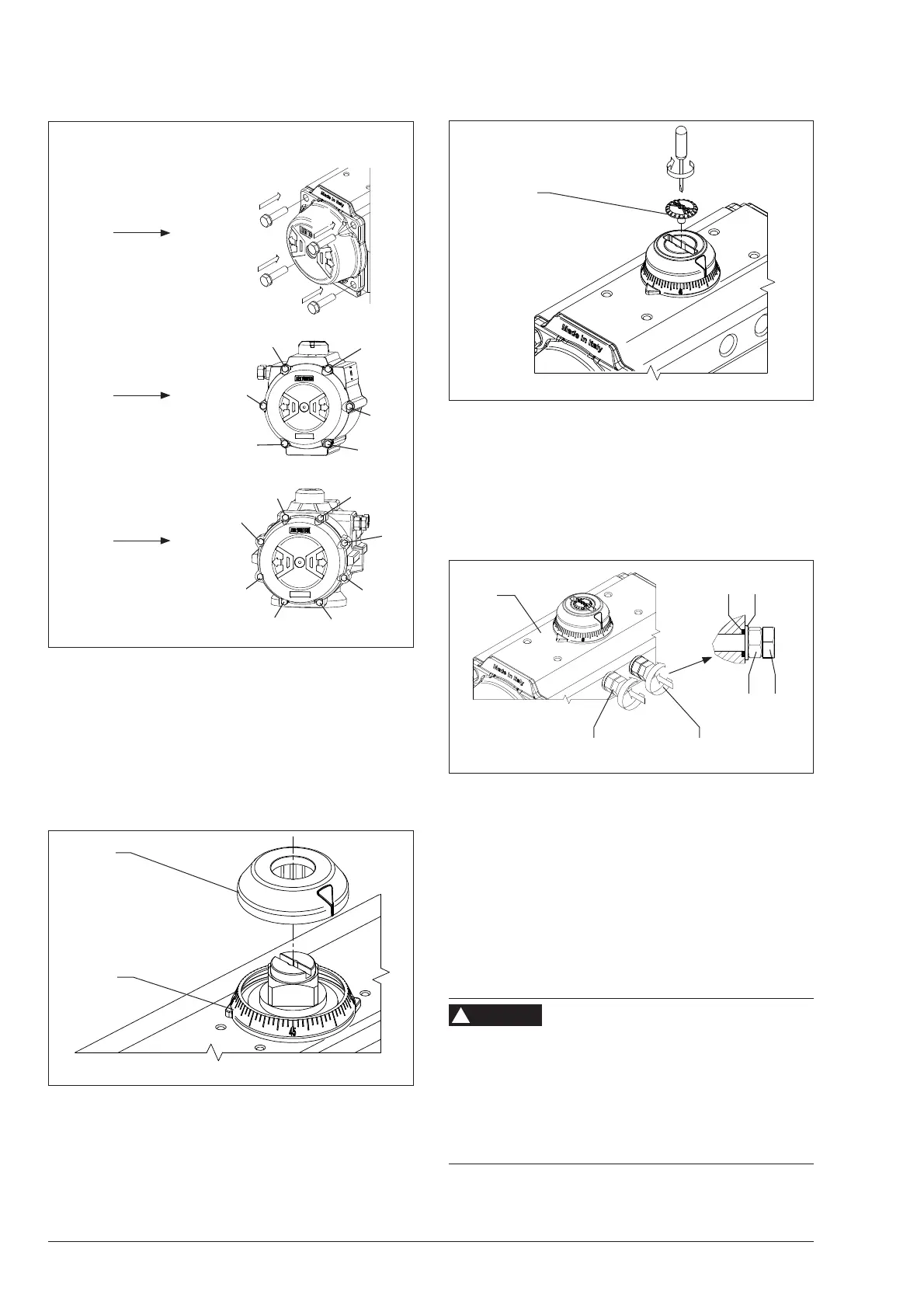

9.5.4 Position indicator reassembly

Refer to Fig. 9-1, Fig. 9-22 and Fig. 9-23.

− Fix the graduated ring (19.0) into the body, if any.

− Place the indicator (19/19.1) referring to the correct actu-

ator position.

− Fasten the indicator screw (39), if any. (Fig. 9-23)

Fig. 9-22

19

19.1

19.0

39

Fig. 9-23

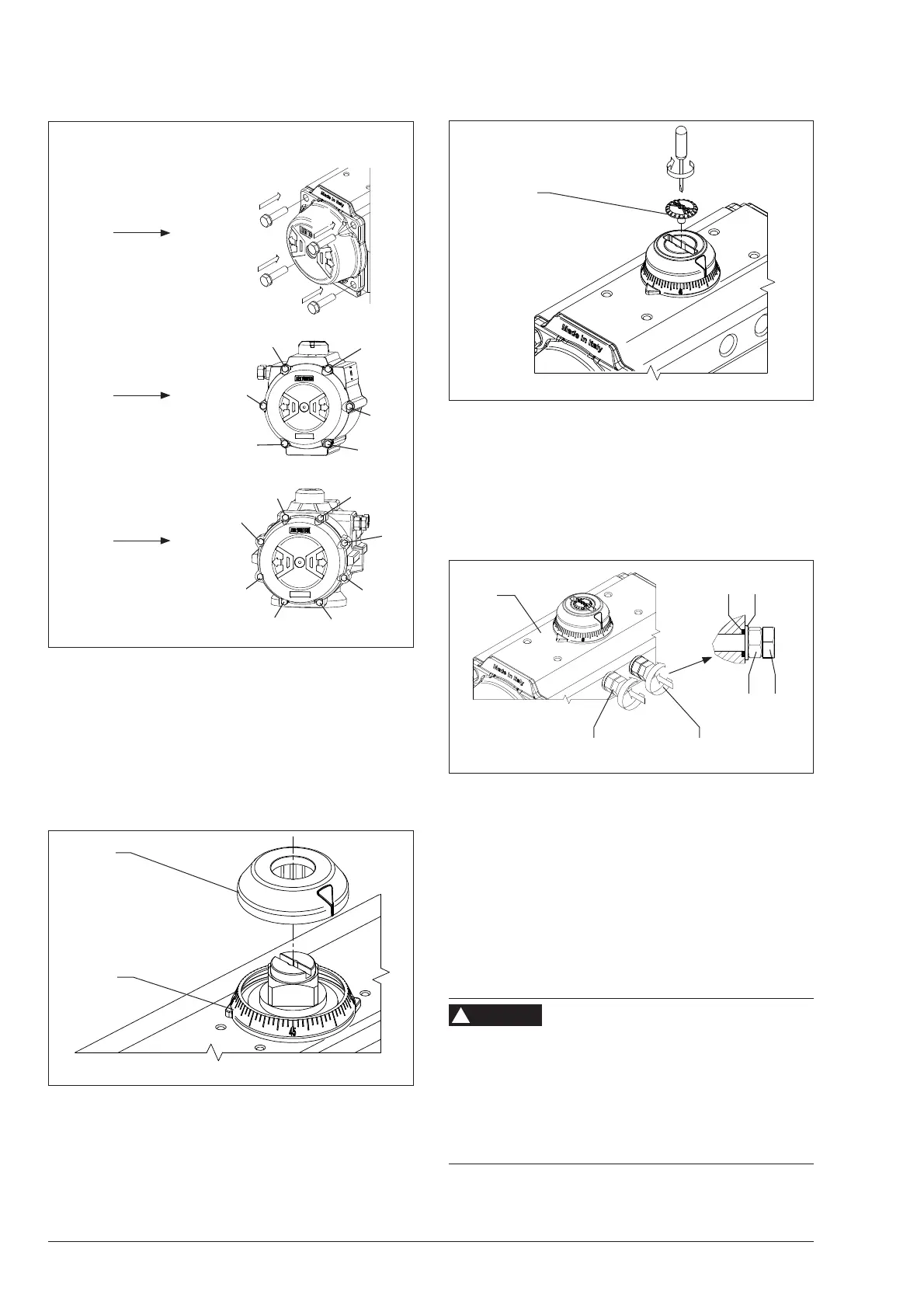

9.5.5 Stop cap screws reassembly

Refer to Fig. 9-1 and Fig. 9-24.

− Insert onto both stop screws (02), the nut (04), the washer

(03) and the o-ring (11).

− Place the stop cap screws (02) into the body (50).

Fig. 9-24

50

LEFT RIGHT

0204

0311

9.5.6 Stroke adjustment

Refer to Fig. 9-1 and Fig. 9-24.

Close position

− With the actuator in close position (0° position) referring

to Fig. 9-15 for pistons position, screw or unscrew the

right stop screw (02) 1 turn at a time until the desired stop

position is achieved. In case of spring return actuator, a

pneumatic supply may be necessesary.

Risk of personal injury due to pneumatic supply.

Stop screws are not still properly tightened. Any pneumatic

supply can eject the stop screws out from the actuator body.

Î Before starting pressurizing the actuator, make sure the

stop screws are screwed at least for a legth equal to the

screw diameter. Refer to the ‘Tightening torques‘ (Table

15.3) for the screw dimensions.

WARNING

!

Loading...

Loading...