Heatless Regenerative Desiccant Air Dryer | AHLD Series

11

How It Works

1. Moisture saturated compressed air enters the coalescing

pre-lter, where aerosols are coalesced then drained via

an automatic drain system.

2. The moist water vapor-laden inlet air free of liquid

water ows to the inlet of the dryer through the APV

(Automatic Piston Valve) (A), which diverts the inlet air to

one of the towers - in this example, Tower 1.

3. Air ows upward through the adsorbent bed removing

the moisture vapor; the dried airow exits the tower

through the outlet valve (B), owing to the outlet

particulate after lter, which removes particulates

from the air stream. Clean and dry air now ows to the

customer process air distribution system.

4. As one tower is drying air, the other tower will be

regenerating (purging) the adsorbent bed. In this

example, Tower 2 will be regenerating. Prior to

regeneration, the exhaust valve (C) is opened and the

tower is depressurized to near atmospheric pressure, the

tower will now be regenerating. During the regenerating

process, a small portion of dry outlet compressed air is

used, 15% on average based on standard design capacity

of 100 psig, 100°F inlet air, 100°F ambient air, and

pressure dew point of -40°F.

5. The dry regeneration airow is channeled through

the outlet orice to the regenerating tower, removing

moisture from the adsorbent bed and exits the

regenerating tower through exhaust valve (C) and

exhaust muer to ambient. After regeneration cycle

is complete, valve (C) closes, causing Tower 2 to

repressurize to line pressure.

6. Next, the tower will switch when exhaust valve (D)

opens, causing Tower 1 to depressurize and regenerate.

Simultaneously, the inlet and outlet APV valves (A) will

shift the pistons to the low pressure Tower 1, causing

the inlet airow to be diverted to Tower 2, which will now

be the drying tower. This switching process will continue

repeatedly.

7. The dryer control system is completely automatic and

cycles the system through the drying and regeneration

cycles. The standard cycle drying time is 5 minutes,

regeneration cycle is 4 minutes, and repressurizing cycle

is 1 minute.

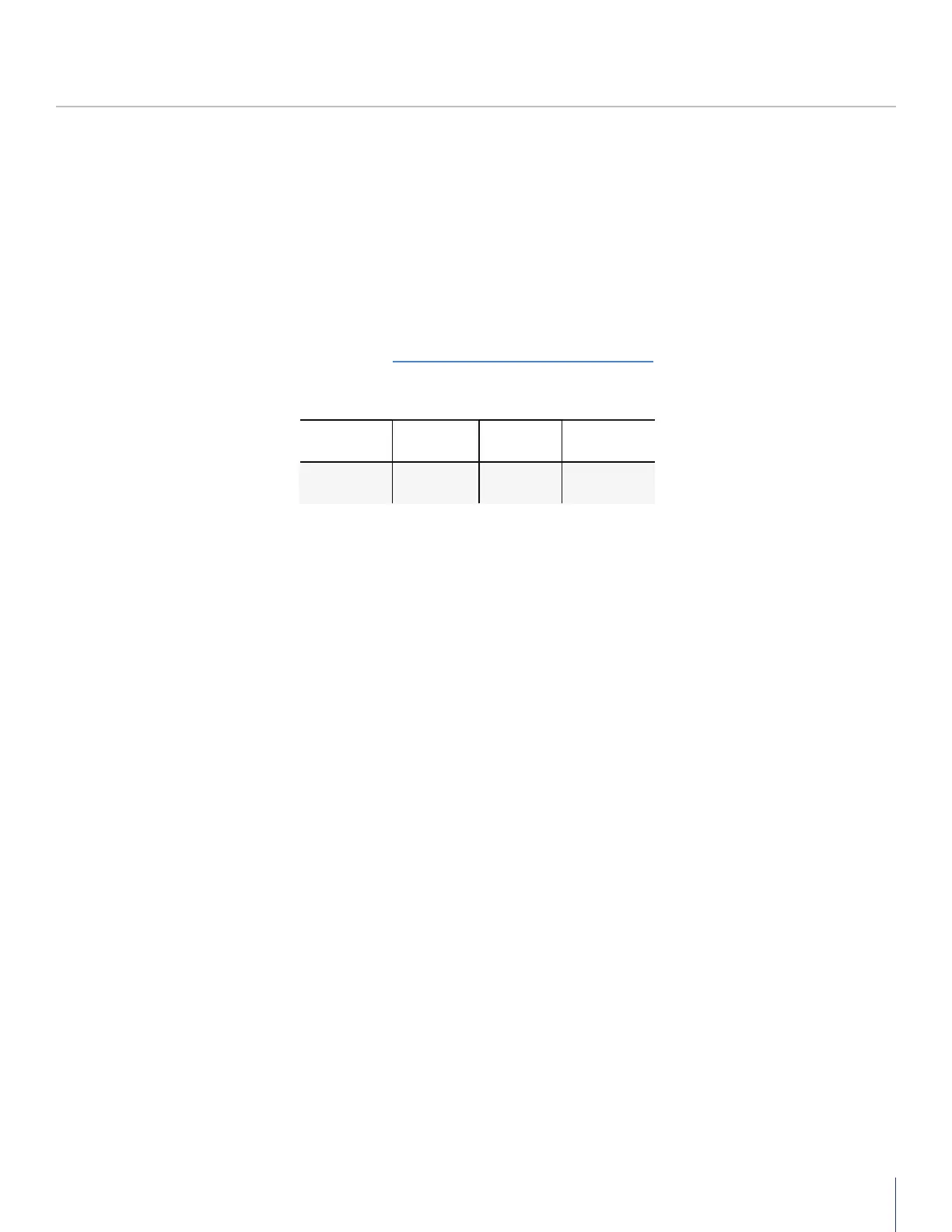

DESIGN PARAMETERS

DRYER DESCRIPTION

Type of dryer: Desiccant

Power supply: 460 Volt / Three Phase / 60Hz

Desiccant type: Premium Grade Activated Alumina

All Models

Parameter

Description Air Pressure

Air Inlet

Temperature

Ambient

Temperature

Maximum 135 psig 120 (°F) 120 (°F)

Minimum 60 psig 40 (°F) 38 (°F)

Loading...

Loading...