AHLD Series | Heatless Regenerative Desiccant Air Dryer

20

AIRCEL PROGRAMMABLE CONTROLLER (APC)

Dryer Operations

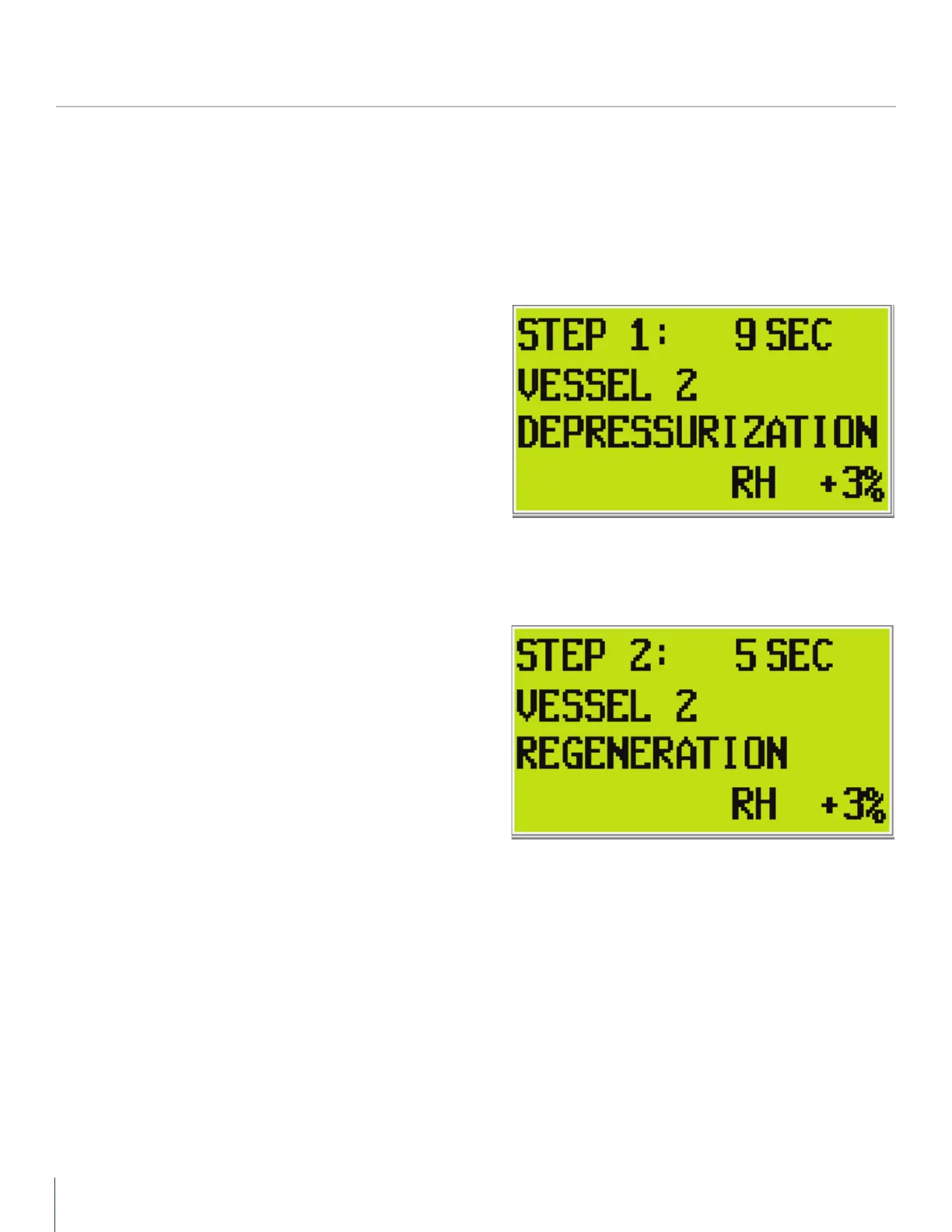

STEP ONE: Select Vessel 2 Depressurizing (0 - 5 seconds)

Vessel 2 (T2) purge exhaust pilot solenoid valve is energized,

supplying control air to slowly open the purge exhaust valve

(V4), depressurizing vessel 2 (T2).

Simultaneously, the inlet valves V1 and V2 shift positions with

a pneumatic signal from vessel 2 (T2) purge exhaust pilot

solenoid valve to the inlet tower selector pneumatic pilot valve.

This action supplies a pneumatic signal to the inlet valves to

open valve (V1) and close valve (V2), directing the inlet air to

vessel 1 (T1) to dry the air.

The air flows up through the desiccant bed and exits outlet

valve (V5) to the outlet particulate filter. The air then moves

down the line, to the customer dry process air system.

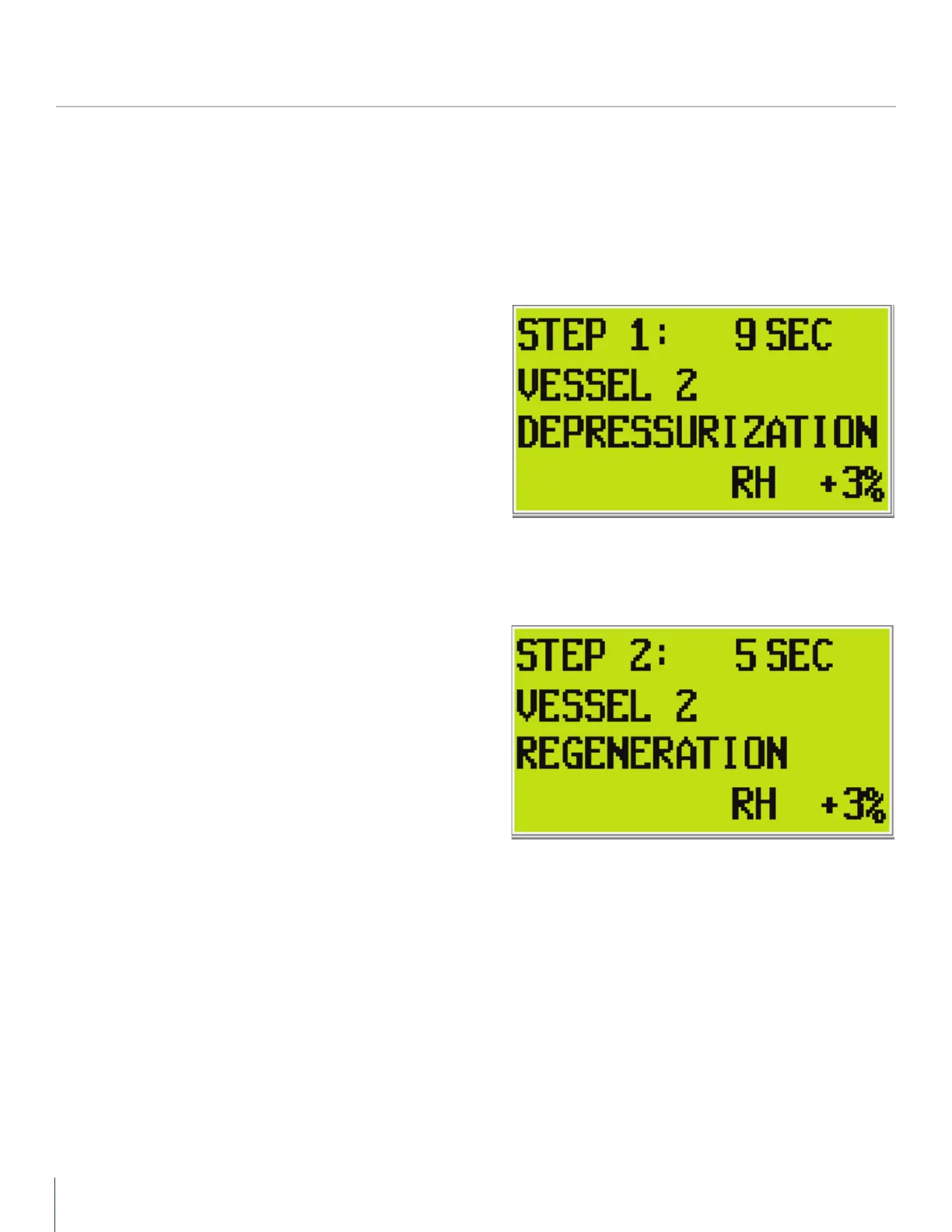

STEP TWO: Vessel 2 Regenerating (6 - 240 seconds)

Vessel 2 (T2) is regenerating, Vessel 2 (T2) purge exhaust valve

(V4) is still open, Vessel 1 (T1) is drying the inlet air.

A small portion of dry outlet air from Vessel 1 (T1) (15% average

based on standard design capacity of 100 psig, 100°F ambient

air and PDP of -40°F) is taken through a small orifice in the

outlet line and used to regenerate the desiccant bed in Vessel 2

(T2) until 240 seconds has been reached.

The timer on this step counts to 240 seconds (4-minutes).

A warning sign will flash in the upper right hand portion of the

screen and a red LED alarm light will flash on the PLC display

for any alarm. To view alarms, press the left arrow once from

the main screen.

The screen also displays the relative humidity reading and dew

point (optional).

Loading...

Loading...