AHLD Series | Heatless Regenerative Desiccant Air Dryer

30

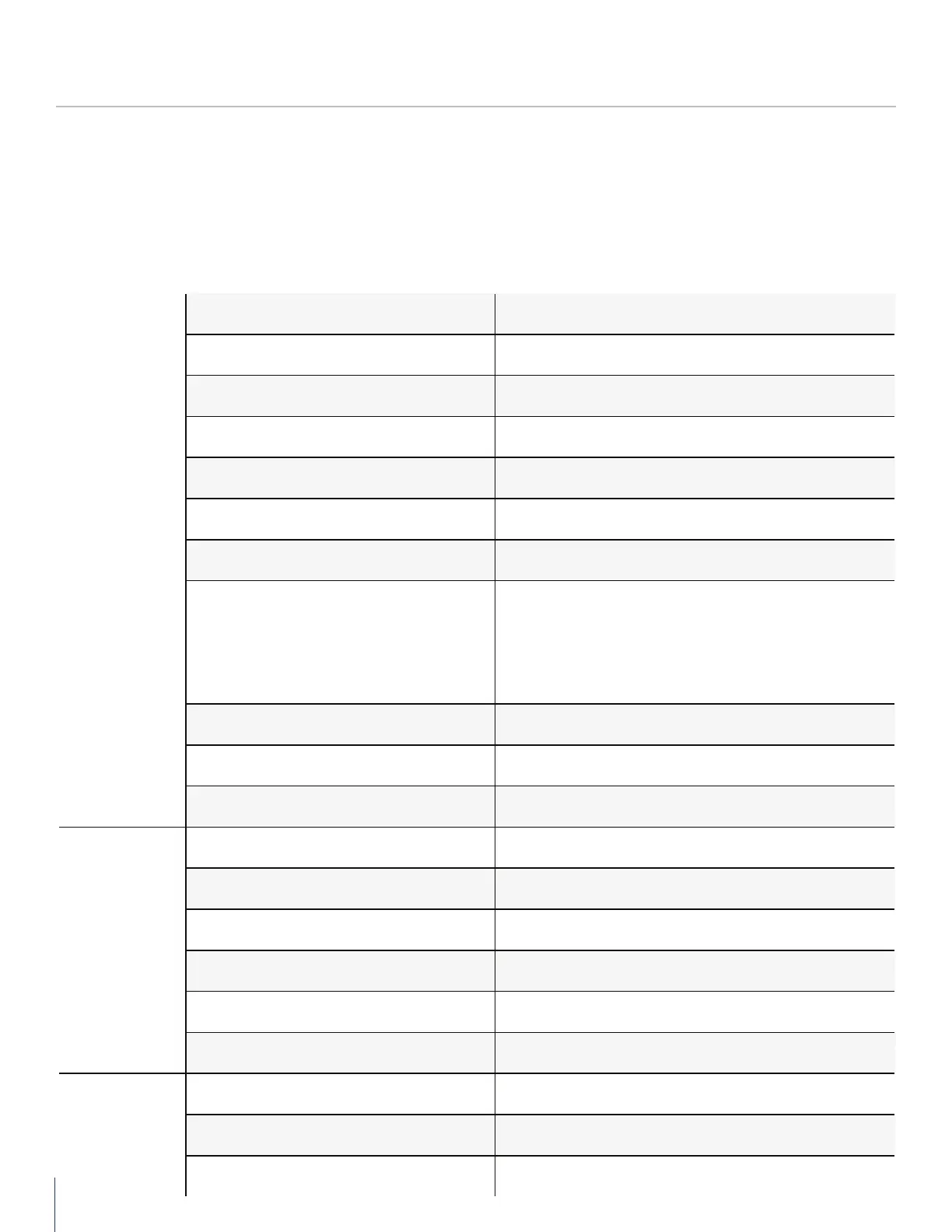

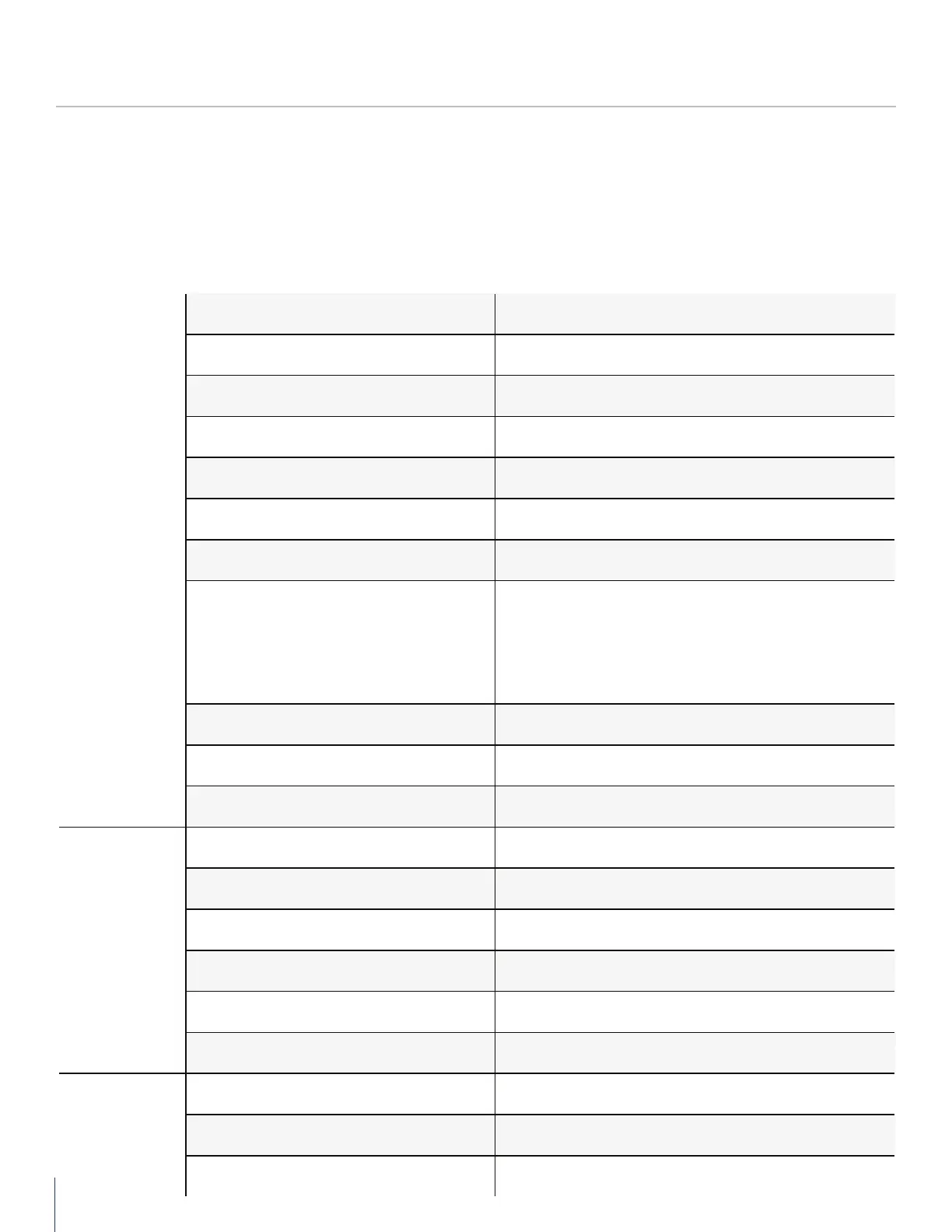

TROUBLESHOOTING TABLE

Problem Probable Cause Remedy

High Dew Point

High inlet air ow Reduce inlet air ow

Inlet air temperature above design spec Reduce inlet air temperature to design spec

Poor pre-ltration Check pre-lter element, replace if needed

Inlet air pressure below design spec Increase pressure to the dryer

Desiccant contaminated Replace desiccant

Purge ow orice in the outlet APV valve may

be clogged

Dismantle outlet APV valve, and clean out the orice

Back pressure in regenerating chambers Muers are clogged, install new muers

Exhaust valve(s) not fully opening or closing

Check pilot valve and pilot air supply, dismantle and clean

exhaust valve, check ow control valve attached to purge

exhaust valve actuator may not be adjusted properly (should

be adjusted so exhaust valve opens within a 8-12 minute

time period)

APV valve leaking Dismantle and clean, replace seals and piston if needed

No input power Check that dryer is on with correct voltage

Controller failure Check, replace if needed

High Pressure

Drop

Low inlet pressure Increase inlet pressure to design pressure

Desiccant dusting High inlet ow velocities due to high ow

Inlet pre-lter dirty Inspect and replace as needed

High inlet ow rate Reduce inlet ow rate to meet dryer spec

Outlet lter dirty Inspect and replace as needed

Desiccant diuser screens clogged Inspect and clean as needed

High Back Pressure

in Regenerating

Tower

Purge muer clogged Clean and replace if needed

Desiccant diuser screens clogged Inspect and clean as needed

Restrictive purge exhaust piping Clean and replace with larger pipe if required

Loading...

Loading...