Hole Drilling

Cored Fiberglass Hull—Follow separate instructions on page 4.

1. Drill a 3mm or 1/8" pilot hole perpendicular to the waterline from

inside the hull (see Figure 2). If there is a rib, strut, or other hull

irregularity near the selected mounting location, drill from the outside.

2. Using the 51mm or 2" hole saw, cut a hole from outside the hull.

Be sure to hold the drill plumb, so the hole will be perpendicular

to the water surface.

3. Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there is

any petroleum residue inside the hull, remove it with either mild

household detergent or a weak solvent (alcohol) before sanding.

Cutting the Standard Fairing

CAUTION: The button on the fairing points forward toward the

bow. Be sure to orient the fairing on the band saw so the angle cut

matches the intended side of the hull and not the mirror image.

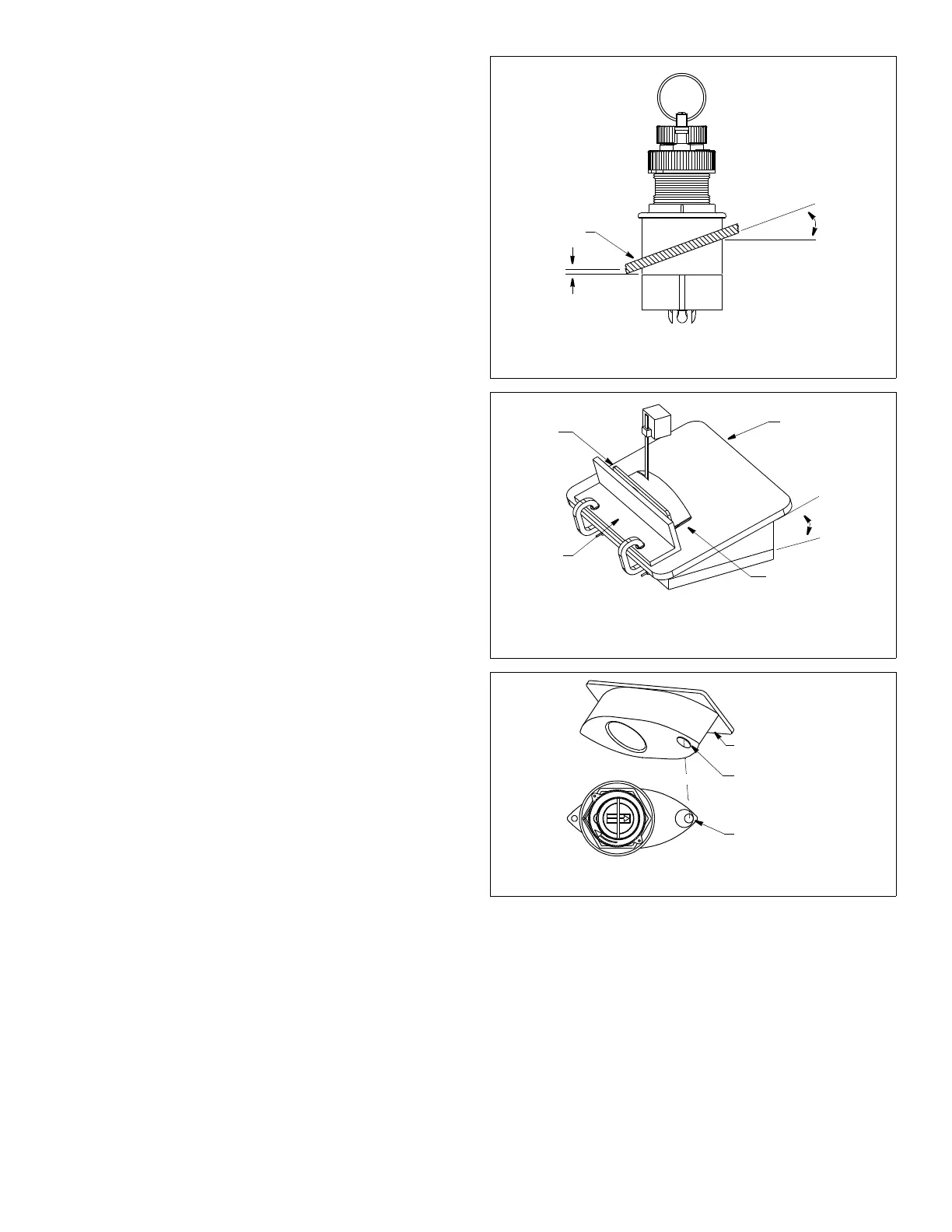

1. Measure the deadrise angle of the hull at the selected location

using an angle finder or a digital level (see Figure 3).

2. Tilt the band saw table to the measured angle and secure the

cutting fence (see Figure 4).

3. Place the Standard Fairing on the table, so the cutting guide

rests against the fence. The button will point toward you for

installation on the starboard side and away from you for

installation on the port side of the boat (see Figure 5).

4. Adjust the cutting fence so the fairing will be cut in about two

equal parts. The section that will become the fairing must be

between 6–12mm (1/4–1/2") at its thinnest dimension (see

Figure 3).

5. Recheck steps 1 through 4. Then cut the fairing.

6. Shape the fairing to the hull as precisely as possible with a rasp

or power tool.

7. Use the remaining section of the fairing with the cutting guide

for the backing block.

Bedding

CAUTION: Be sure all surfaces to be bedded are clean and dry.

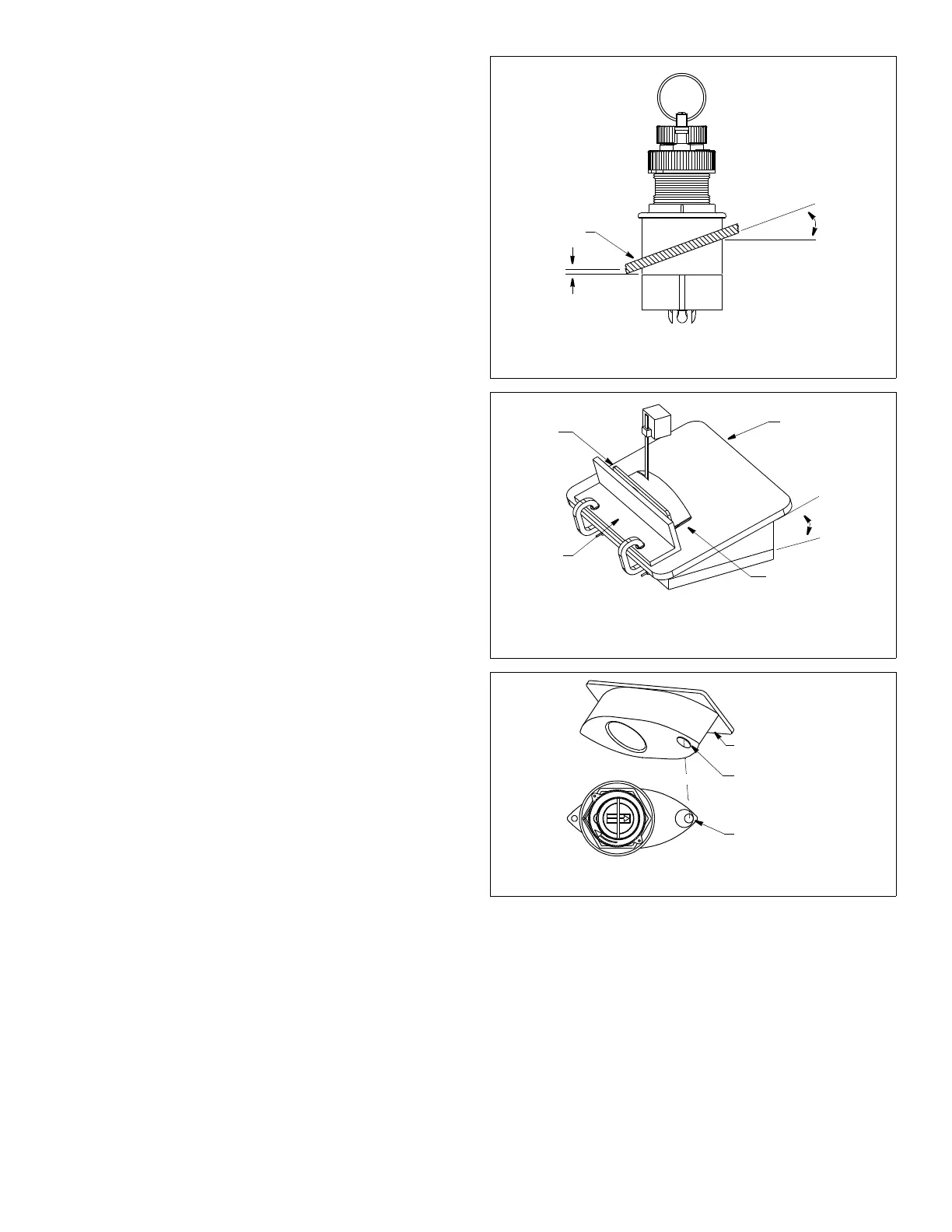

1. Remove the hull nut (see Figure 2).

2. Apply a 2mm (1/16") thick layer of marine sealant over the

surface of the sensor housing that will contact the fairing and up

the stem. The sealant must extend 6mm (1/4") higher than the

combined thickness of the fairing, hull, backing block, and hull

nut. This will ensure there is marine sealant in the threads to seal

the hull and hold the hull nut securely in place.

3. Apply a 2mm (1/16") thick layer of marine sealant to the surface

of the:

• Fairing that will contact the hull

• Backing block that will contact the hull interior

• Hull nut that will contact the backing block

4. Thread the cable through the fairing. Slide the fairing onto the

stem and mate the button with the recess in the sensor’s

housing (see Figure 5).

Installing the Housing

CAUTION: B744V/VL—Be careful to avoid cross threading the

CAP nut.

1. From outside the hull, thread the cable through the mounting hole.

Then push the stem of the sensor housing through the hole using

a twisting motion to squeeze out excess sealant. Be sure the

3

Figure 4. Cutting the Standard Fairing

button

Figure 5. Airmar Standard Fairing (B744V shown)

BOW ►

6–12mm (1/4–1/2")

backing

hull

Standard

sensor

deadrise

fairing thickness

angle

slope of hull

parallel to

waterline

block

Figure 3. Deadrise angle and fairing thickness (B744V shown)

at thinnest point

recess in

sensor housing

cutting guide

Copyright © 2005 - 2010 Airmar Technology Corp.

Copyright © 2005 - 2010 Airmar Technology Corp.

Copyright © 2005 - 2010 Airmar Technology Corp.

standard

Fairing

cutting

guide

band saw

table

deadrise

angle

button end

for installation

on starboard

fence

side of the hull

button on the fairing is mated with the recess in the sensor and it

is pointing forward toward the bow (see Figure 5). Take care to

align the assembly parallel to the centerline of the boat.

2. From inside the hull, slide the backing block onto the stem and

seat it firmly against the hull, being sure the pointed end faces

forward toward the bow (see Figure 2). Screw the hull nut in

place. Tighten it with slip-joint pliers.

Cored fiberglass hull—Do not over tighten, crushing the hull.

Wood hull—Allow the wood to swell before tightening.

3. B744V/VL—Being sure the valve assembly is seated firmly

within the housing, carefully screw the CAP nut in place. Hand-

tighten only. Do not over tighten.

4. Remove any excess sealant on the outside of the fairing and

the hull to ensure smooth water flow under the sensor.

Aft View

fairing

Loading...

Loading...