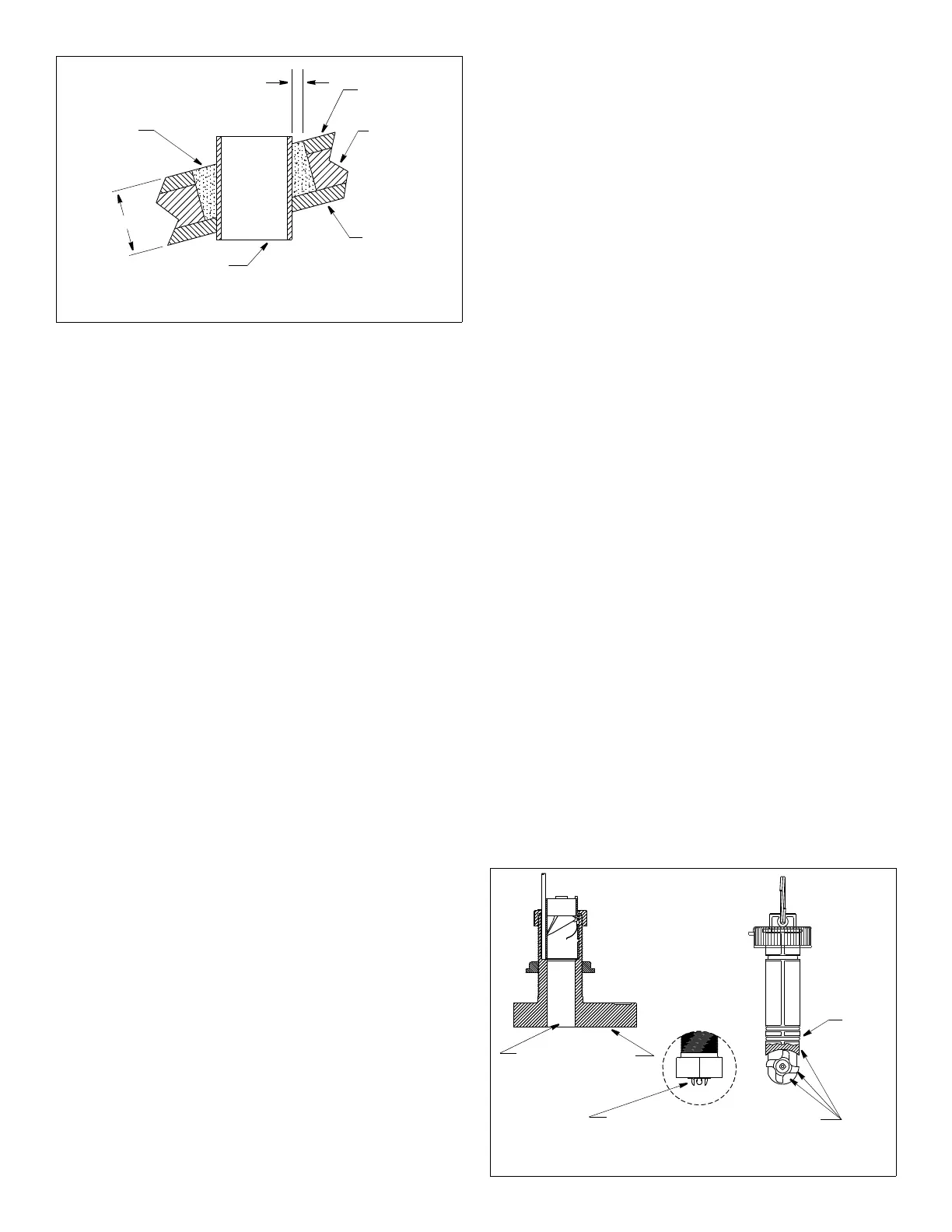

hull’s outer skin to

hull

outer skin

solid or hollow

cylinder

pour in

casting

epoxy

core

inner skin

Figure 8. Preparing a cored fiberglass hull

Dimension equal to

the thickness of the

ensure adequate

clearance

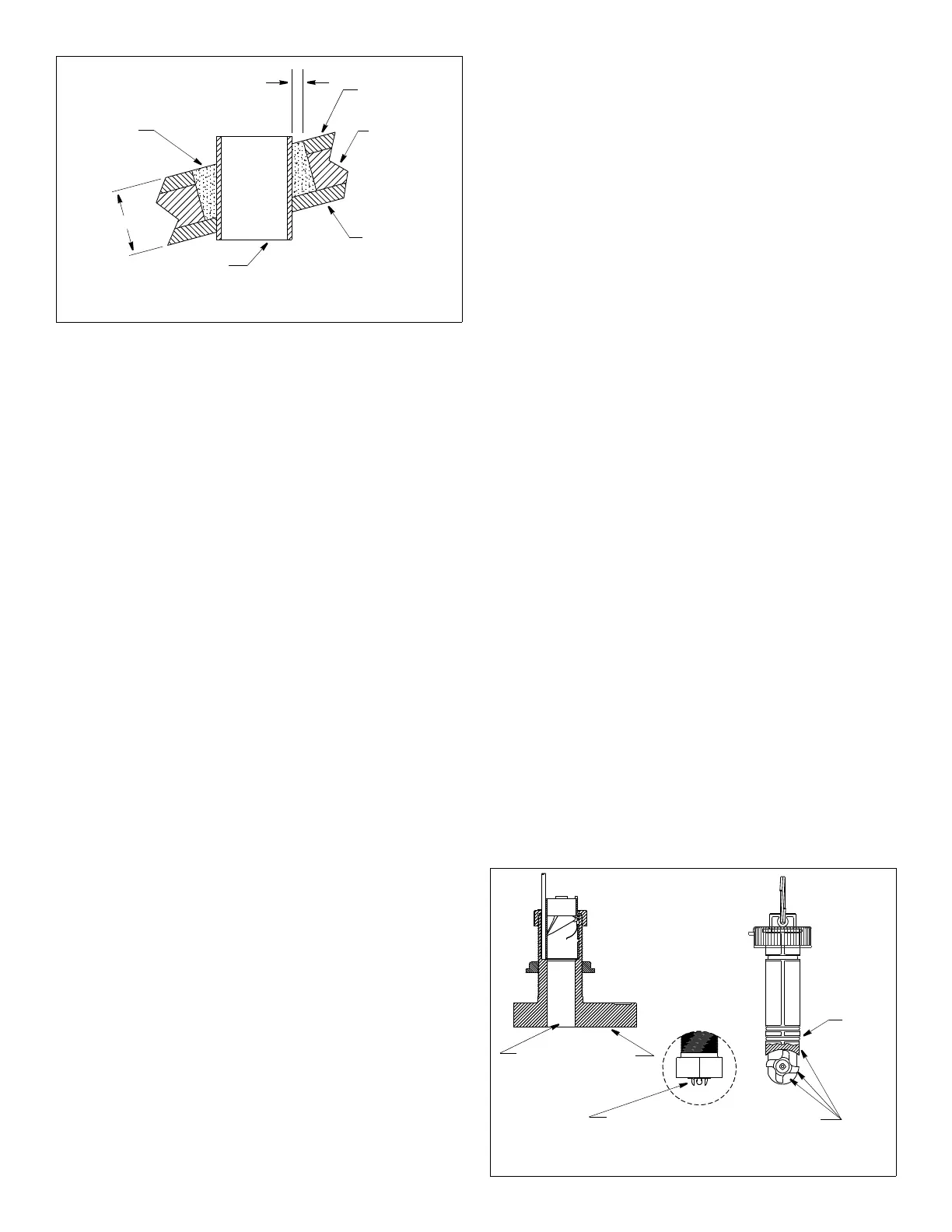

Figure 9. Anti-fouling paint (B744V shown)

Paint outside wall below the lower O-ring

including exposed end, paddlewheel cavity and paddlewheel

Paint exposed housing

lower

O-ring

and bore up 30 mm (1-1/4")

paddlewheel

insert

housing

detail

6. Sand and clean the area around the hole, inside and outside, to

ensure that the sealant will adhere properly to the hull. If there is

any petroleum residue inside the hull, remove it with either mild

household detergent or a weak solvent (alcohol) before sanding.

7. Proceed with “Cutting the Standard Fairing” on page 3.

Cable Routing & Connecting

CAUTION: If the sensor came with a connector, do not remove it

to ease cable routing. If the cable must be cut and spliced, use

Airmar’s splash-proof Junction Box No. 33-035 and follow the

instructions supplied. Removing the waterproof connector or

cutting the cable, except when using a water-tight junction box,

will void the sensor warranty.

1. Route the cable to the instrument, being careful not to tear the

cable jacket when passing it through the bulkhead(s) and other

parts of the boat. Use grommets to prevent chafing. To reduce

electrical interference, separate the sensor cable from other

electrical wiring and the engine. Coil any excess cable and

secure it in place using cable ties to prevent damage.

2. Refer to the echosounder owner’s manual to connect the

sensor to the instrument.

Check for Leaks

When the boat is placed in the water, immediately check around

the sensor for leaks. Note that very small leaks may not be readily

observed. Do not leave the boat in the water for more than 3

hours before checking it again. If there is a small leak, there may

be considerable bilge water accumulation after 24 hours. If a leak

is observed, repeat “Bedding” and “Installing” immediately (see

page 3).

Operation & Maintenance

Anti-fouling Paint

Surfaces exposed to salt water must be coated with anti-fouling

paint. Use water-based anti-fouling paint only. Never use ketone-

based paint since ketones can attack many plastics possibly

damaging the transducer. Reapply paint every 6 months or at the

beginning of each boating season.

B744V/VL: Additional Anti-fouling Paint

Paint the following surfaces (see Figure 9).

• Exposed areas of the housing including the transducer’s face

• Bore of the housing up 30mm (1-1/4")

• Outside wall of the paddlewheel insert below the lower O-ring

• Paddlewheel cavity

• Paddlewheel

• Blanking plug below the lower O-ring including the exposed end

Cleaning the Sensor

Aquatic growth can accumulate rapidly on the sensor’s surface,

reducing its performance within weeks. Clean the surface with

mild household detergent and a Scotch-Brite® scour pad.

B744V/VL—If fouling on the insert is severe, push out the

paddlewheel shaft using a spare shaft or a 4-D finish nail with a

flattened point. Then lightly wet sand the paddlewheel with fine

grade wet/dry paper.

B744V/VL: How the Valve Works

WARNING: The valve is not a watertight seal!

Always install the paddlewheel insert or the blanking plug secured

with the insert nut and safety wire for a watertight seal.

The multisensor incorporates a self-closing valve which minimizes

the flow of water into the vessel when the paddlewheel insert is

removed (see Figure 6). The curved flap valve is activated by both

a spring and water pressure. Water pushes the flap valve upward

to block the opening, so there is no gush of water into the boat.

B744V/VL: Using the Blanking Plug

To protect the paddlewheel, use the blanking plug:

• When the boat will be kept in salt water for more than a week.

• When the boat will be removed from the water.

• When aquatic growth buildup on the paddlewheel is suspected

due to inaccurate readings from the instrument.

1. On the blanking plug, inspect the O-rings (replace if necessary)

and lubricate them with silicone lubricant or petroleum jelly

(Vaseline®) (see Figure 6). The O-rings must be intact and well

lubricated to make a watertight seal.

2. Remove the paddlewheel insert from the housing by removing

the safety wire from the pull ring and the insert nut (see

Figure 7). Unscrew the insert nut. Do not remove the CAP nut,

as the valve assembly will come out.

3. Grasp the pull ring and remove the paddlewheel insert with a

slow pulling motion.

NOTE: In the unlikely event that the paddlewheel insert cannot

be removed, see “Servicing the Valve Assembly” on page 6.

4. Slide the blanking plug into the housing. Seat it into place with a

pushing twisting motion until the keys fit into the notches (see

Figure 6). Screw the insert nut in place and hand-tighten only.

Do not over tighten.

5. Reattach the safety wire (see Figure 7).

5

Copyright © 2005 Airmar Technology Corp.

Copyright © 2005 Airmar Technology Corp.

Loading...

Loading...