7

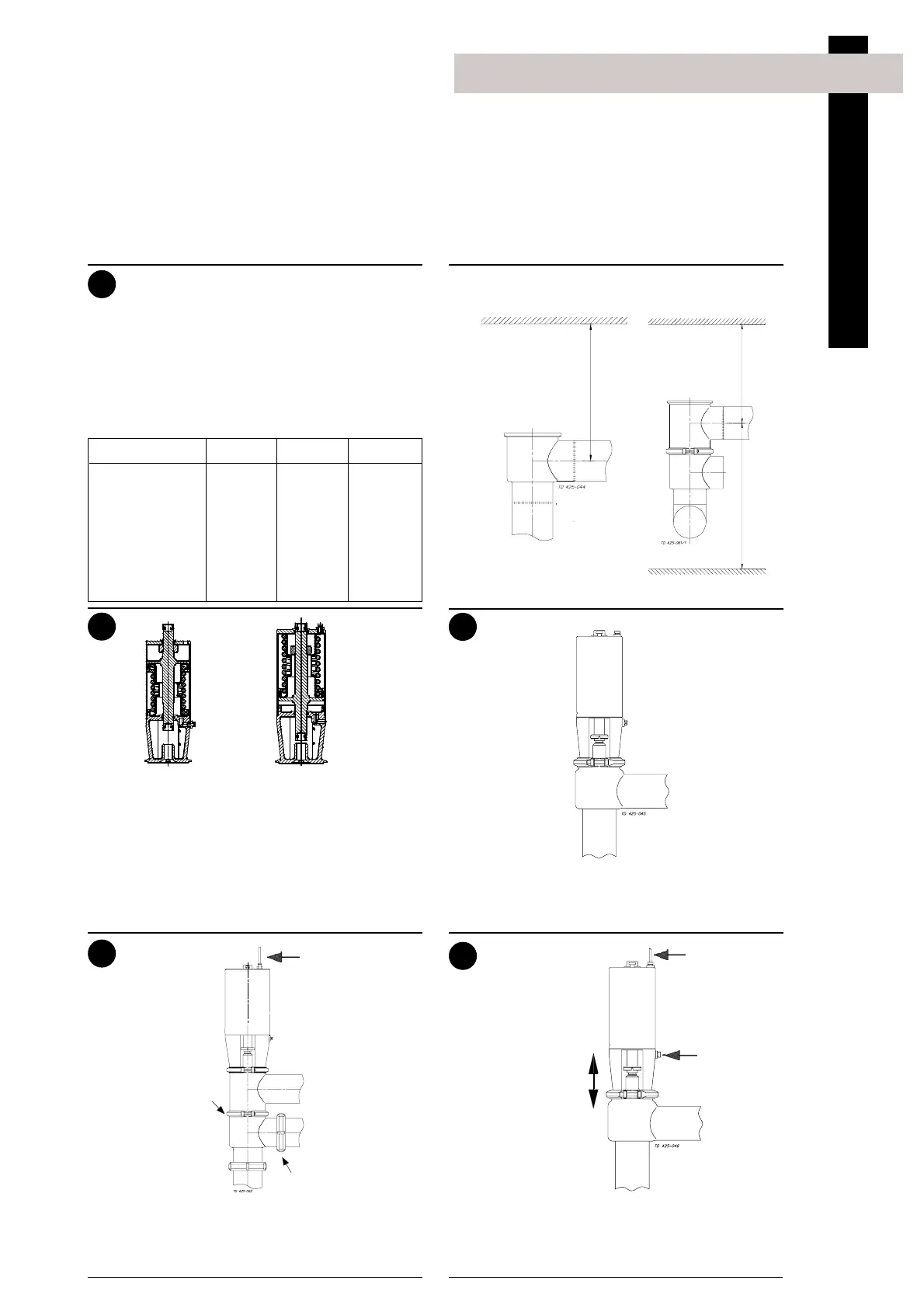

Valve size A (mm) B

1

(mm) B

2

(mm)

DN25/25 mm 200 537 647

DN40/38 mm 230 550 730

DN50/51 mm 290 550 730

DN65/63.5 mm 350 550 730

DN80/76 mm 390 600 780

DN100/101.6 mm 490 650 830

DN125 580 730 920

DN150 640 730 920

1

2

4

3

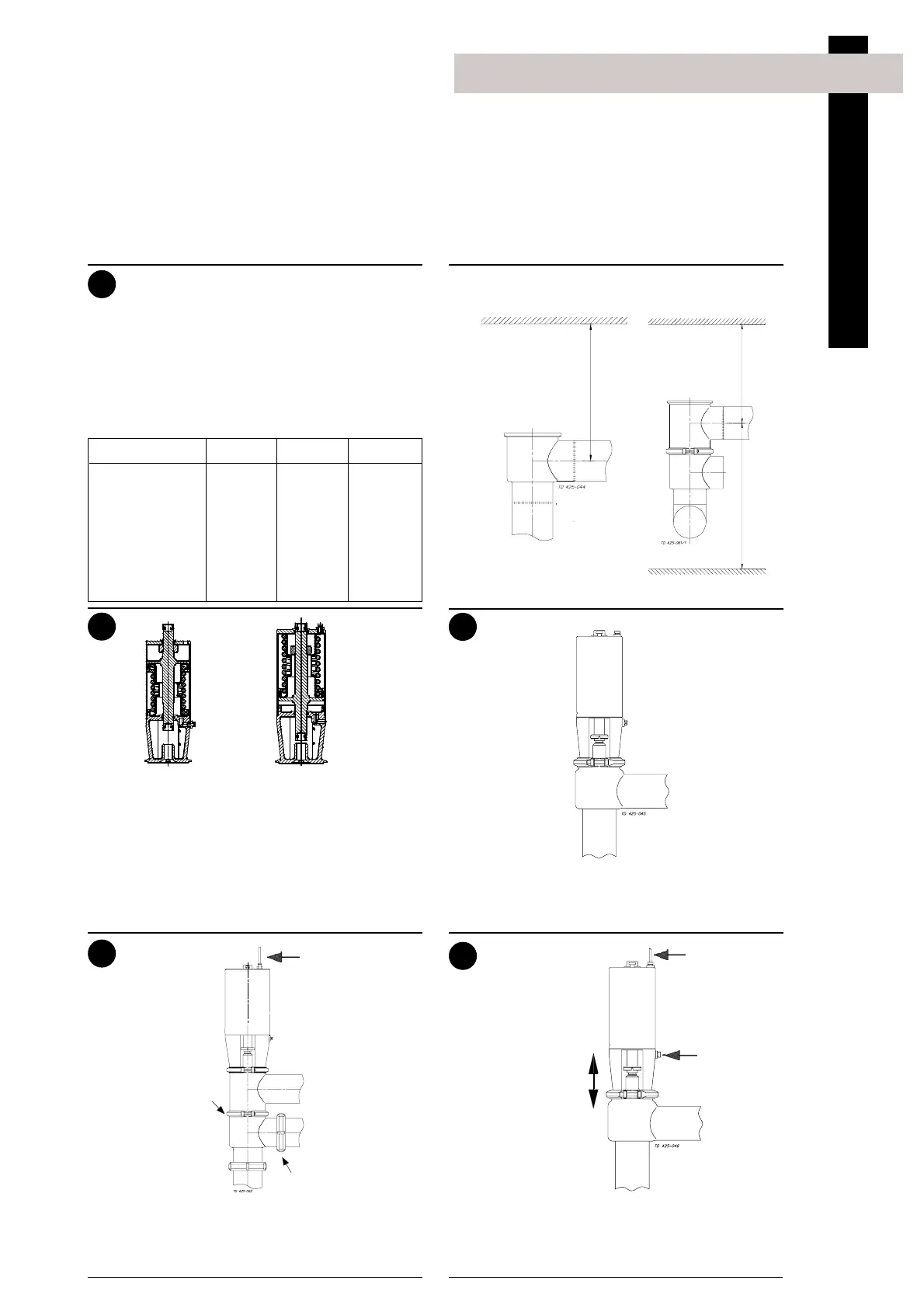

Study the instructions carefully.

The valve is supplied as separate parts to facilitate the

welding.

The items refer to the drawings and the parts list on the

pages 22-37.

Check the valve for smooth operation after welding.

3. Welding

Always weld the valve so that the valve body seal

ring can be replaced (change-over valve).

Maintain the minimum clearances (A and B) so that

the lower valve body and plug (change-over valve)

and the actuator with the internal parts can be

removed.

Stop valve:

Assemble the valve in accordance with the

instructions 2-5 on page 18.

Pay special attention to the warnings!

Change-over valve:

Assemble the valve in accordance with the instruc-

tions 2-6 on page 18.

Pay special attention to the warnings!

Pre-use check:

1. Supply compressed air to the actuator.

2. Open and close the valve several times to

ensure that it operates smoothly.

Pay special attention to the warnings!

Change-over valve

(upper valve body)

Stop valve

B

1

B

2

(incl. top unit)

Fit seal ring (17)

correctly!

Remember

seal rings!

Air

Open/close!

Installation

B

1

B

2

(incl.

top unit)

A

5

SRC 25 mm stop valve

The 25 mm actuator is only for use on the SRC 25

mm stop valve.

Warning: When changing from NC to NO please

note that the actuator is spring-loaded. For safety,

place a "Spring-loaded" warning label (ordered

from Technical Support at Alfa Laval) on the valve.

Air (NO/AA)

Air (NC/AA)

Loading...

Loading...