8

1

2

5

6

3

4

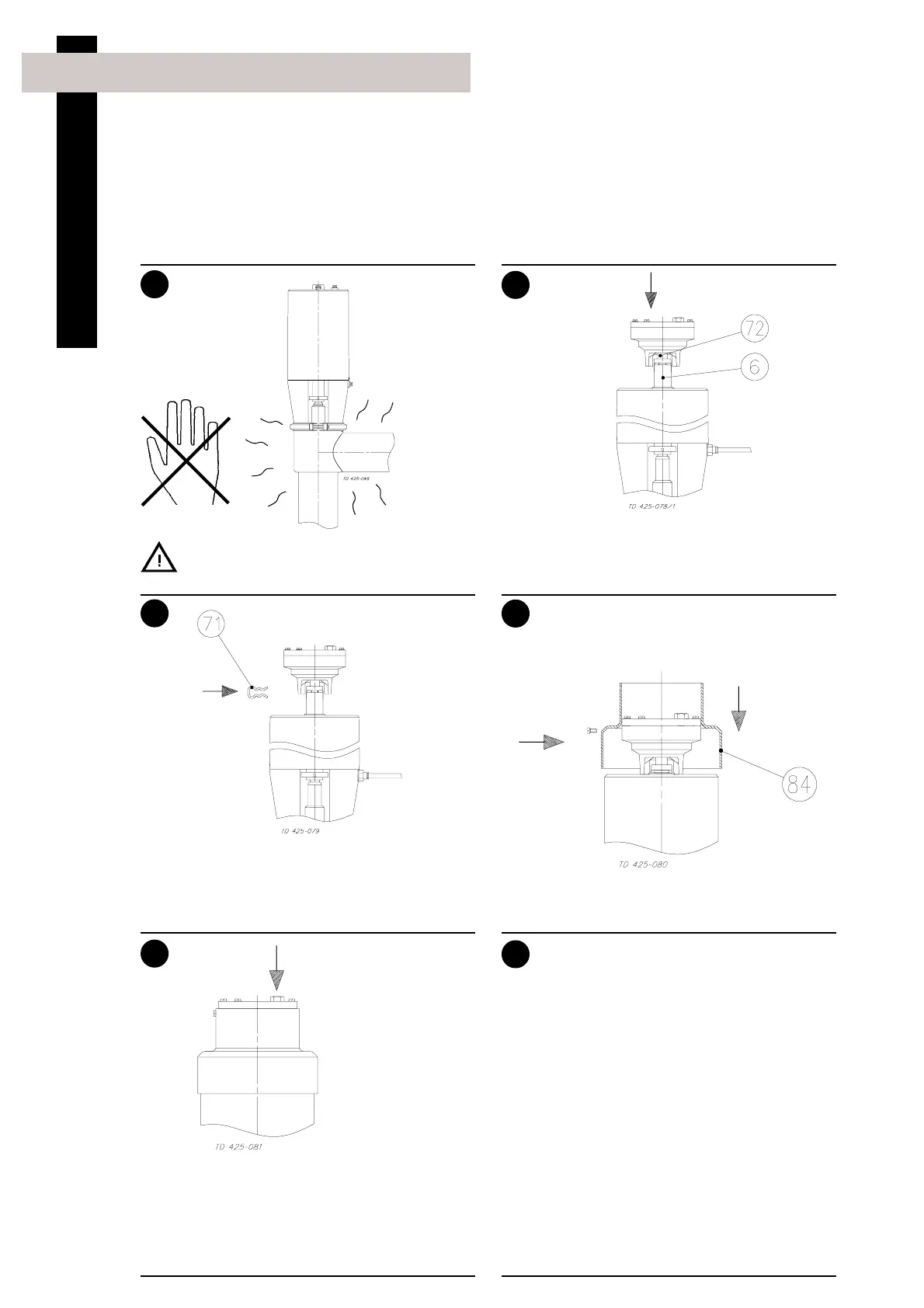

The valve can be fitted with an oil damper if water

hammer occurs when the valve closes in the flow

direction.

The items refer to the drawings and the parts list on

pages 38-41.

Study the instructions carefully and pay special

attention to the warnings!

NC = normally closed.

A/A = air/air activated.

4. Fitting of oil damper, 25-101.6 mm/DN25-100, optional extra

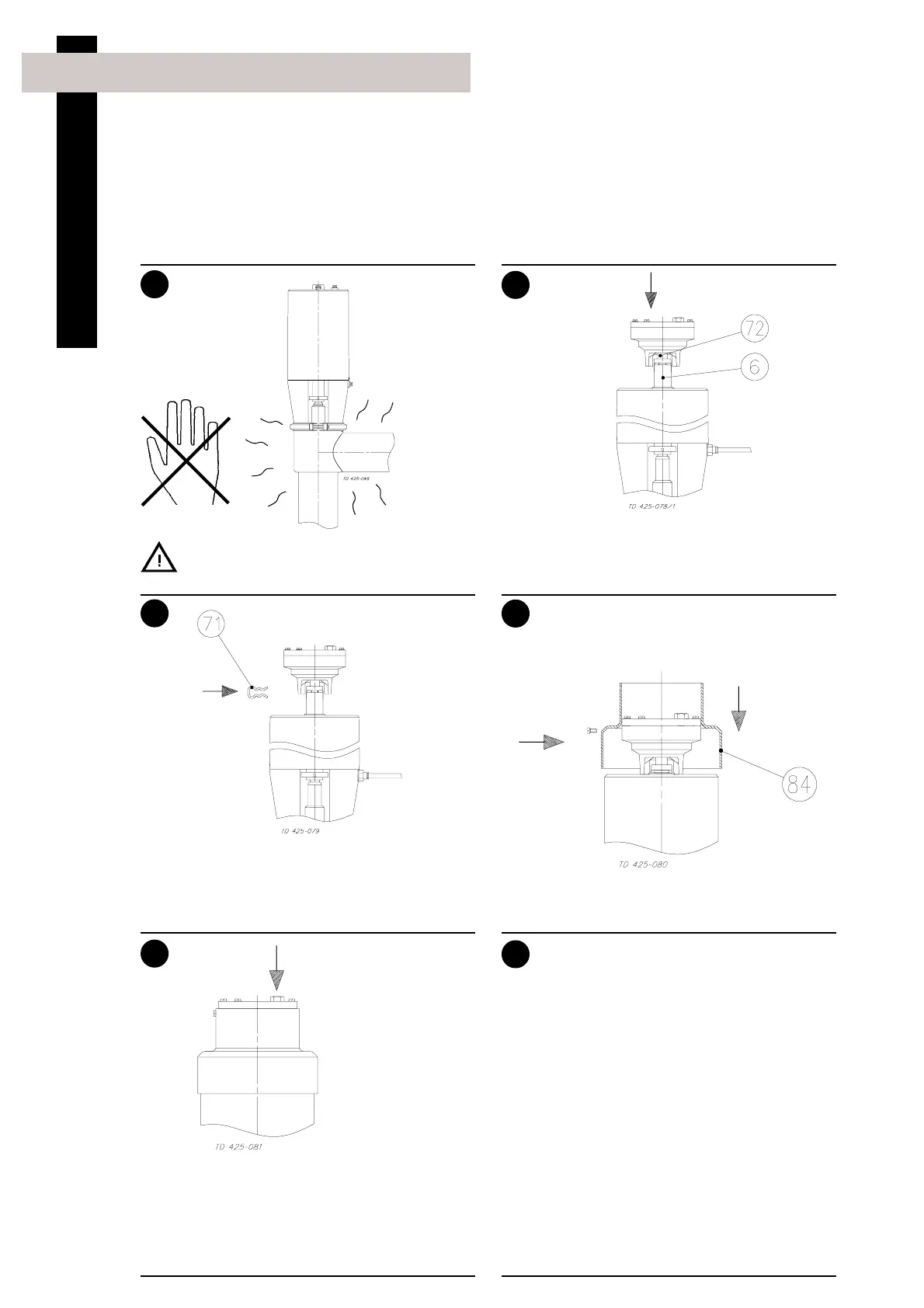

Fill further oil through the plug hole if large air

bubbles occur under the plexiglas cover.

NOTE!

There should be a small air bubble which equalizes

changes in the pressure because of temperature

changes.

Removal/dismantling:

Remove the damper by following the instructions in

reverse order.

Pre-use check:

1. Supply compressed air to the actuator.

2. Open and close the valve several times to

ensure that it operates smoothly.

Pay special attention to the warnings!

Never touch the valve or the pipelines when

processing hot liquids or when sterilizing.

Burning danger!

1. Supply compressed air to the actuator.

Pay special attention to the warnings!

2. Fit the damper so that damper piston rod (72)

enters actuator piston rod (6).

Oil type SAE 40

Ensure that

no other

equipment

is fitted on the

actuator top!

1. Fit protective hood (84).

2. The valve is now ready for operation.

1. Connect the two piston rods by means of clip

(71).

2. Release compressed air to the actuator.

Pay special attention to the warnings!

Air (NC, A/A)

Installation

Air (NC, A/A)

Loading...

Loading...