11

OPEN

CLOSED

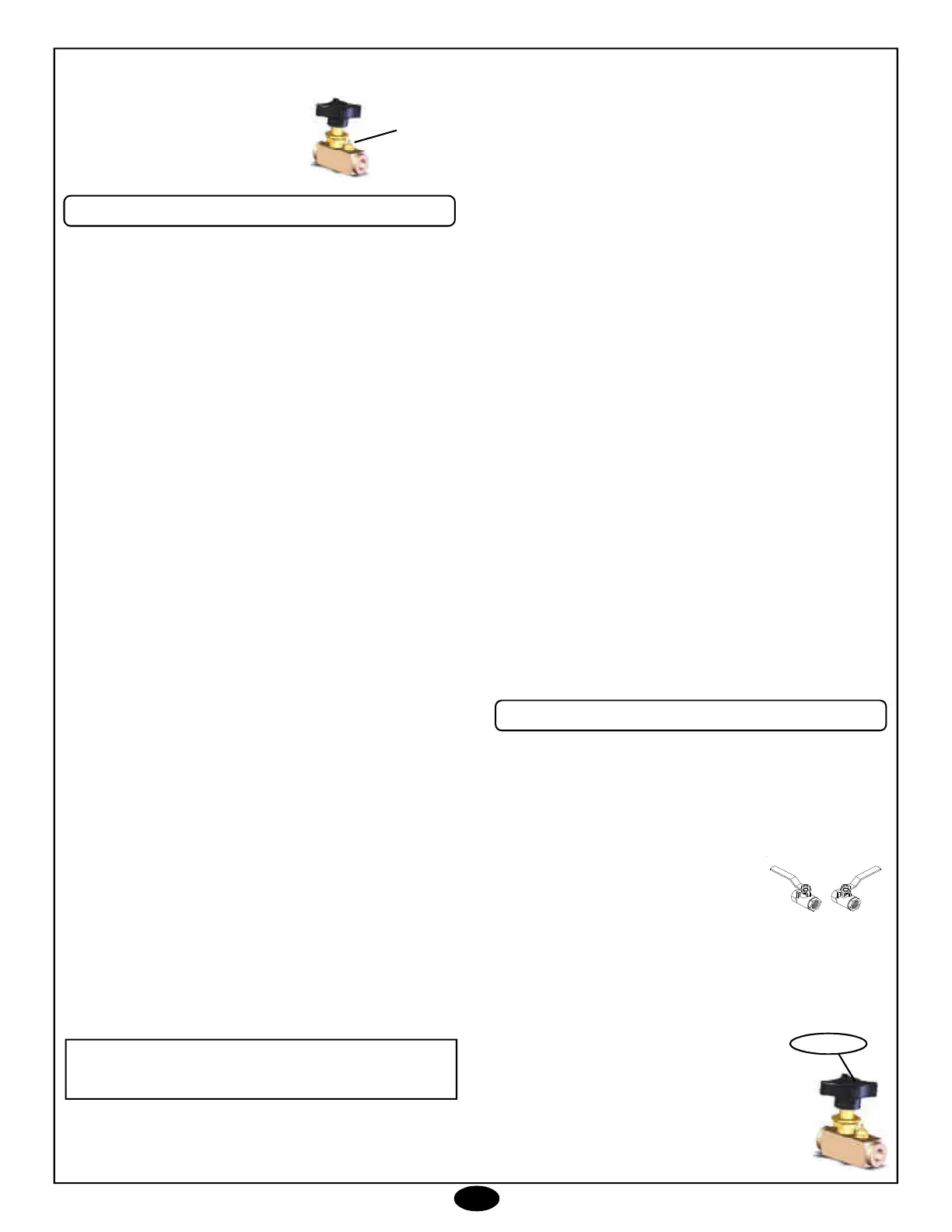

BALL VALVE POSITION

3. With a small common screw driver turn the screw

on the metering valve (if so equipped) counter

clockwise to DECREASE the

temperature and clockwise to

INCREASE the temperature.

1. Install the open gun assembly.

2. With the gun assembly in hand (on trigger gun models

hold the trigger gun valve in open position) and with a

good flow of water, turn the switch to “pump” position.

CAUTION: A good flow of water must be flowing from

the end of a gun for 30 seconds, before proceeding.

Lack of water can cause damage to the water pump

and like components.

CAUTION: On a machine equipped with a trigger gun

valve, if the trigger gun valve remains in the closed

position for more than 3 minutes, water pump damage

may occur.

3. Turn the switch to the “burner” position

CAUTION: Do not run the machine with the burner

switch in the on position when the fuel tank is empty

or with tank valves closed. This will cause damage to

the fuel pump and void warranty.

CAUTION: Do not operate with the trigger gun valve

closed for more than 3 minutes or water pump damage

may occur.

4. To CLEAN:

A. Start on the lower portion of the area to be cleaned

and work up using long, even, overlapping strokes.

B. Dirt is generally removed easily if grease and/or oil

is not present. However if grease and/or oil are

present, hot water and chemical will accelerate in the

cleaning process.

5. TO APPLY CHEMICAL:

CHEMICAL: Use factory recommended chemicals for

best cleaning action and for extended pump life.

Contact your dealer for chemicals available. Follow

instructions on chemical container.

Note : If the valve is open without the chemical line

in a source the water pump will draw air causing the

system not to pressure up.

Mix chemicals per label instructions. Use necessary

safety percautions.

When chemical is desired, the system must be

switched over to the low pressure nozzle to draw

chemical.

A. Insert chemical screen into chemical container.

B. If your system is hot water turn the burner switch

to the off postion. There will be air in the soap line.

Air heats very quickly and needs to be eliminated

before the burner can be turned on. Open, counter

clockwise the soap metering valve to up the chemical

line. Once the chemical line is completely full trigger

control gun. Soap should begin moving up the

chemical line. Once the chemical line is completelyfull

trigger, the gun on and off numerous times to break

any possible air locks. Turn burner system switch to

“on” position if equipped.

C. Adjust metering valve or injector. Install your

injector tip.

D. If the gun assembly is equipped with variable or

multiple nozzle assembly, adjust to low pressure .

5. To Rinse: (For cold water rinse, turn the burner

switch off.)

A. If the machine is equipped with a panel mounted

metering valve, close the chemical metering valve.

NOTE: It is advisable to dip the chemical screen in a

container of clean water and open the valve 1 minute

to clean the valve of any remaining residue.

B. If the gun and wand is equipped with variable or

multiple nozzle assembly, open and close to clean

nozzle of any remaining residue.

C. After a clear flow of water is noted from the end of

the wand, start from the top, working downward using

long, overlapping strokes.

1. Turn the burner switch to the “off” position. (If not

already done so in the cold water rinse.)

2. After cool, clear water is coming from the end of the

wand, turn the switch to “off” position.

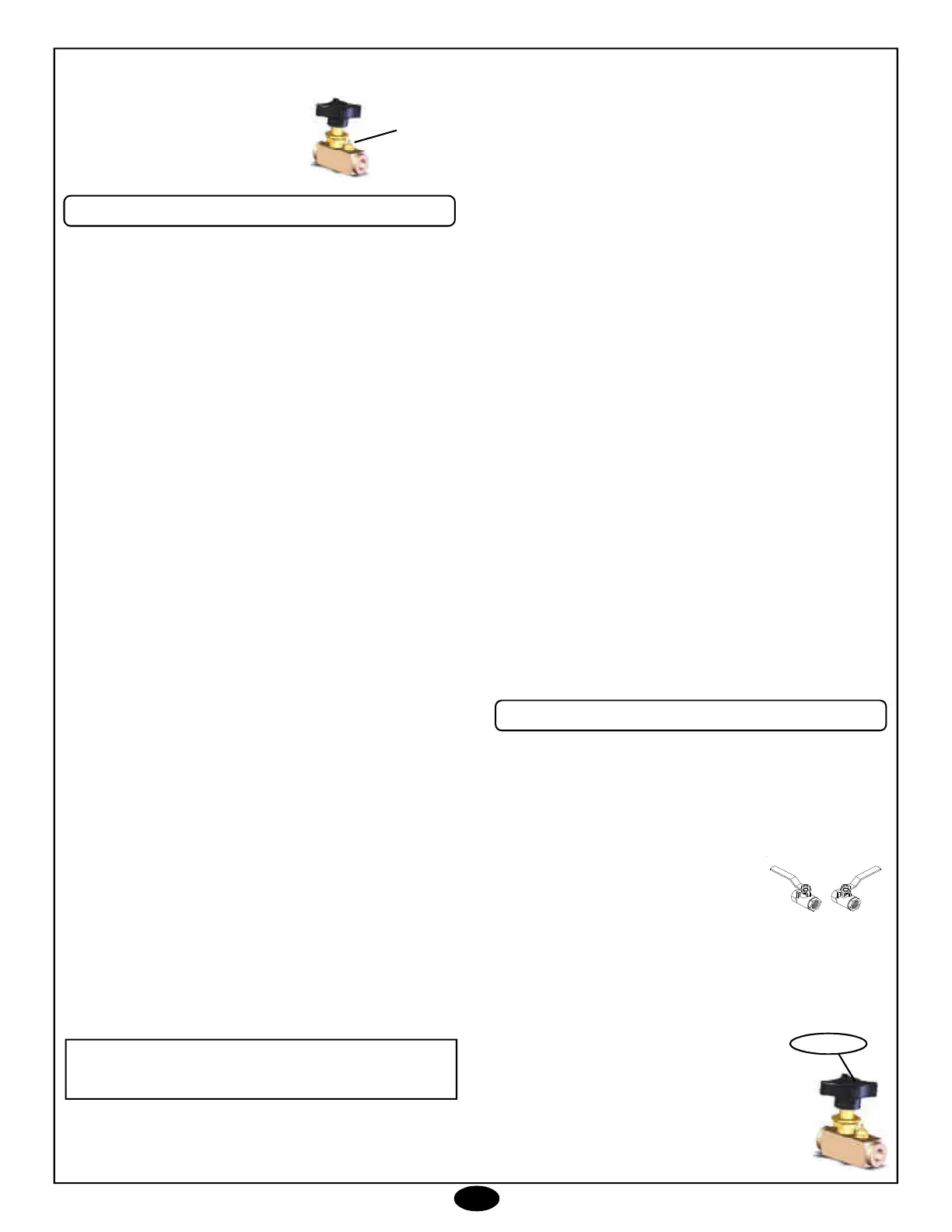

HIGH VOLUME COMBI:

A. Close the water bypass ball

valve (if so equipped) on the coil

inlet assembly.

LOW VOLUME COMBI:

A. Completely Close the water bypass metering valve

(if so equipped) handle turning it clockwise found on

the pump assembly.

3. Turn off the water supply.

4. If freezing conditions may exist,

refer to STORAGE in the section

of MACHINE MAINTENANCE.

5. Replace stack cover (if so

equipped)

05-26-06 Z08-05465A

SHUT-DOWN

OPEN g g

CLOSED g g

START-UP

g

DECREASE

TEMPERATURE

g

g

INCREASE

TEMPERATURE

SCREW

CAUTION: You cannot draw an abrasive product such

as an aluminum brightner. It will cause an

non-warrantable premature pump failure.

Loading...

Loading...