Supersedes 05-25-01 Z08-01793

09-01-04 Z08-01793

1. PRIMING THE MACHINE

Shut off the fuel tank valves. Spin off the element, fill with clean

fuel and coat the square gasket (3) with fuel. Reinstall the

element and tighten 1/4 to 1/3 turns after the gasket contacts

the upper housing. Turn on the fuel tank valves. Start the

machine and check that there are no leaks.

2.

DRAINING WATER

Check the collection bowl daily. Drain off water contaminants

by opening the head vent and then the drain. If more than 1/8

cup of fluid is drained, follow the priming instructions,

otherwise, close the vent and drain. Start the machine and allow

air to purge from the fuel system prior to operating the

equipment.

3. ELEMENT REPLACEMENT FREQUENCY

Frequency of element replacement is determined by con-

tamination level in the fuel. Replace the element upon power

loss of the engine (if so equipped) or every 500 hours

whichever comes first.

NOTE: Foul smelling diesel fuel is an indication of microbio-

logical contamination. A change in fuel source is recommended.

Always carry a spare element as one tank full of contaminated

fuel will plug the fuel filter element prematurely.

4. ELEMENT REPLACEMENT PROCEDURE:

1. Shut off the fuel tank valves.

2. Unscrew the amber bowl from the fuel filter.

3. Unscrew and discard the filter from the upper housing.

4. Follow listed procedures under “PRIMING”.

MAINTENMAINTEN

MAINTENMAINTEN

MAINTEN

AA

AA

A

CE PRCE PR

CE PRCE PR

CE PR

OCEDURESOCEDURES

OCEDURESOCEDURES

OCEDURES

EXPLEXPL

EXPLEXPL

EXPL

ODED ODED

ODED ODED

ODED

VIEWVIEW

VIEWVIEW

VIEW

GASKETS:

1. Inspect for deterioration or tearing.

2. Remove and Replace.

BOWLS:

Inspect rim of bowl to insure it is free

of nicks, cracks, or scratches.

FILTER ELEMENT:

1. Inspect for damage or deterioration.

2. Remove and Replace. (500 hours)

FUEL BOWL:

If contaminants are found, check more

frequently.

NOTE:

intervals stated are for normal operating conditions. the

intervals suggested may be shiortened or lengthened as

determined by existing conditions.

WEEKLY 100 HRS

*

*

*

*

*

*

MAINTENMAINTEN

MAINTENMAINTEN

MAINTEN

ANCE SCHEDULEANCE SCHEDULE

ANCE SCHEDULEANCE SCHEDULE

ANCE SCHEDULE

FILFIL

FILFIL

FIL

TER,TER,

TER,TER,

TER,

FUEL FUEL

FUEL FUEL

FUEL

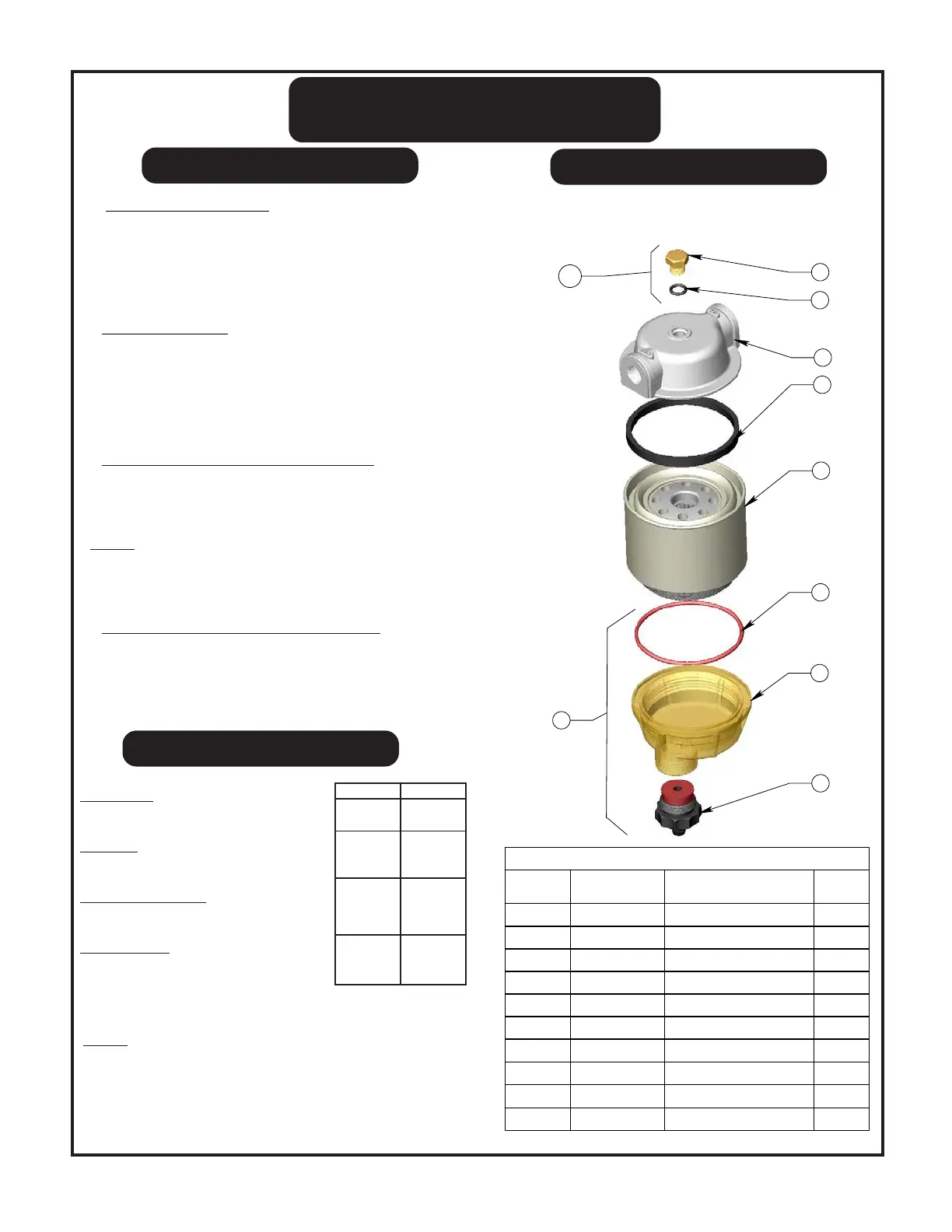

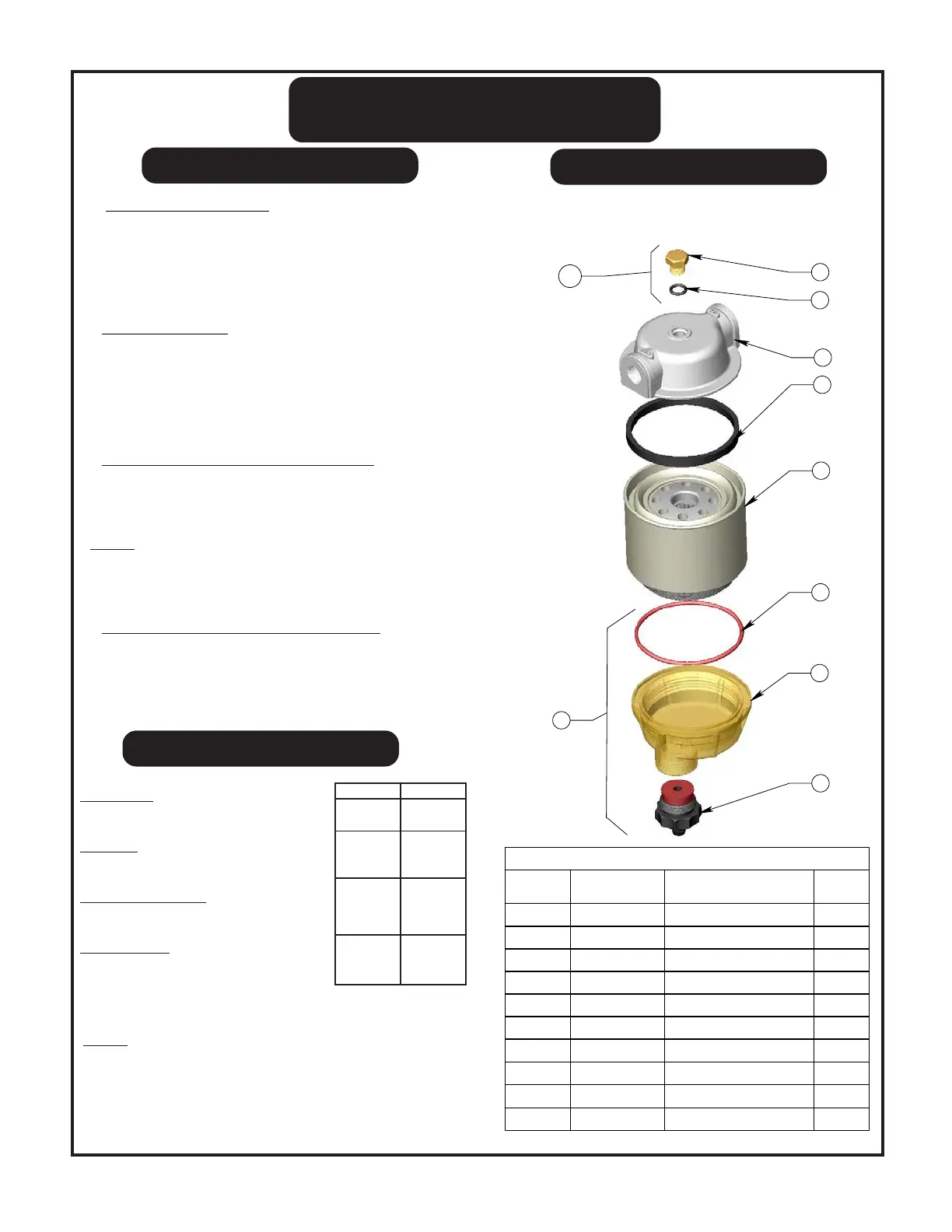

BREAKDOWN - P/N V04-00308

7

6

1

8

4

5

3

2

10

9

PARTS LIST

ITEM PART NUMBER

PART DESCRIPTION

QTY.

1 V04-00308-02

HOUSING, UPPER

1

2 V04-00308-07

ASSEMBLY, DRAIN

1

3 V04-00308-06

BOWL, AMBER - 3"

1

4 V04-00308-01

ELEMENT, FILTER

1

5 V04-00308-05

O-RING - 3/32CS X 2 1/2ID

1

6 C07-01300-08

O-RING - 1/16CS X 5/16ID

1

7 V04-00308-08

PLUG, PIPE

1

8 V04-00308-03

RING, FLAT

1

9 V04-00308-K

KIT, REPLACEMENT

BOWL

1

10 V04-00308-04

ASSEMBLY, VENT

1

PARTS LIST

ITEM PART NUMBER

PART DESCRIPTION

QTY.

1 V04-00308-02

HOUSING, UPPER

1

2 V04-00308-07

ASSEMBLY, DRAIN

1

3 V04-00308-06

BOWL, AMBER - 3"

1

4 V04-00308-01

ELEMENT, FILTER

1

5 V04-00308-05

O-RING - 3/32CS X 2 1/2ID

1

6 C07-01300-08

O-RING - 1/16CS X 5/16ID

1

7 V04-00308-08

PLUG, PIPE

1

8 V04-00308-03

RING, FLAT

1

9 V04-00308-K

KIT, REPLACEMENT

BOWL

1

10 V04-00308-04

ASSEMBLY, VENT

1

Loading...

Loading...