Publication 1763-RM001C-EN-P - October 2009

280 Process Control Instruction

error, the smaller the output signal. An additional value (feed forward or

bias) can be added to the control output as an offset. The PID result

(control variable) drives the process variable toward the set point.

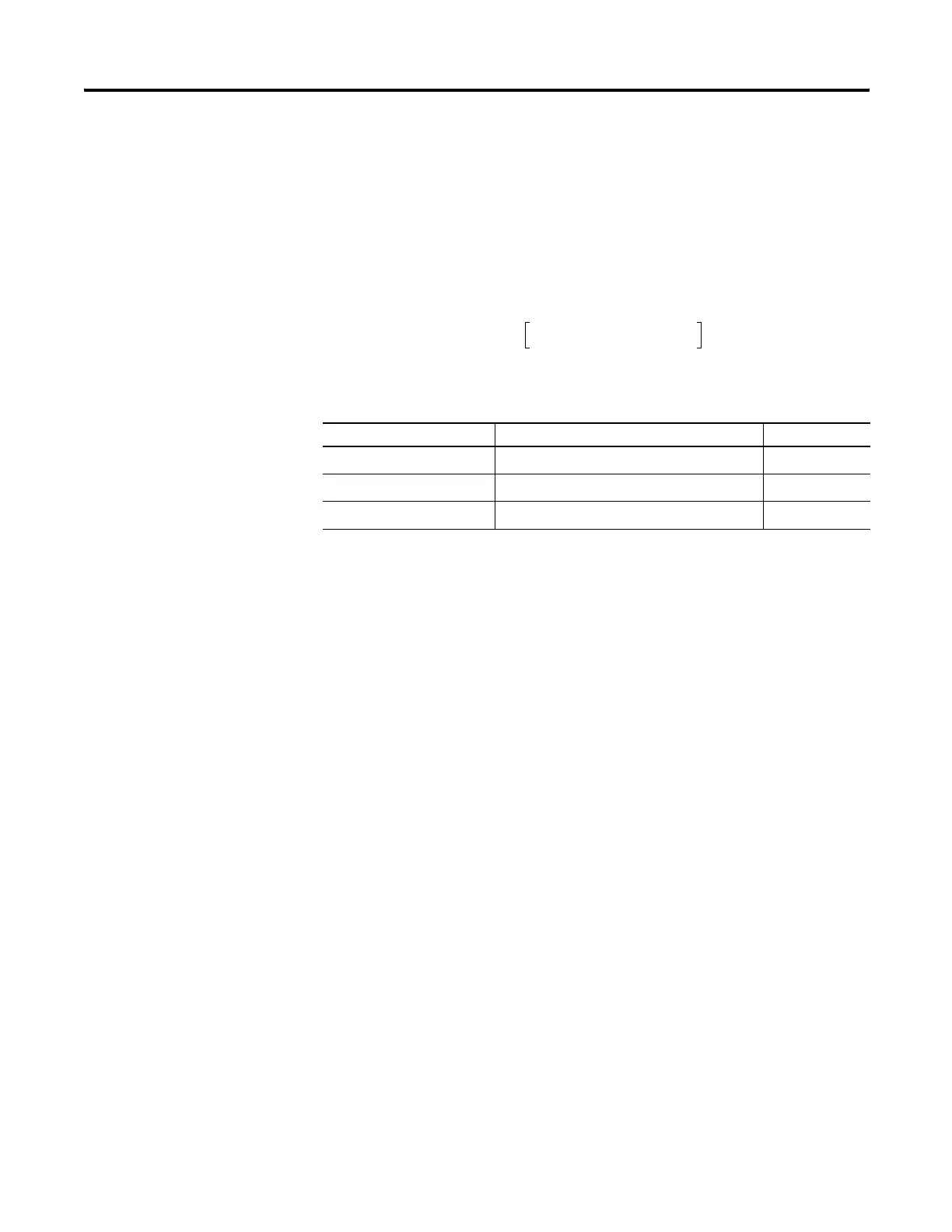

The PID Equation

The PID instruction uses the following algorithm:

Standard equation with dependent gains:

Standard Gains constants are:

The derivative term (rate) provides smoothing by means of a low-pass

filter. The cut-off frequency of the filter is 16 times greater than the corner

frequency of the derivative term.

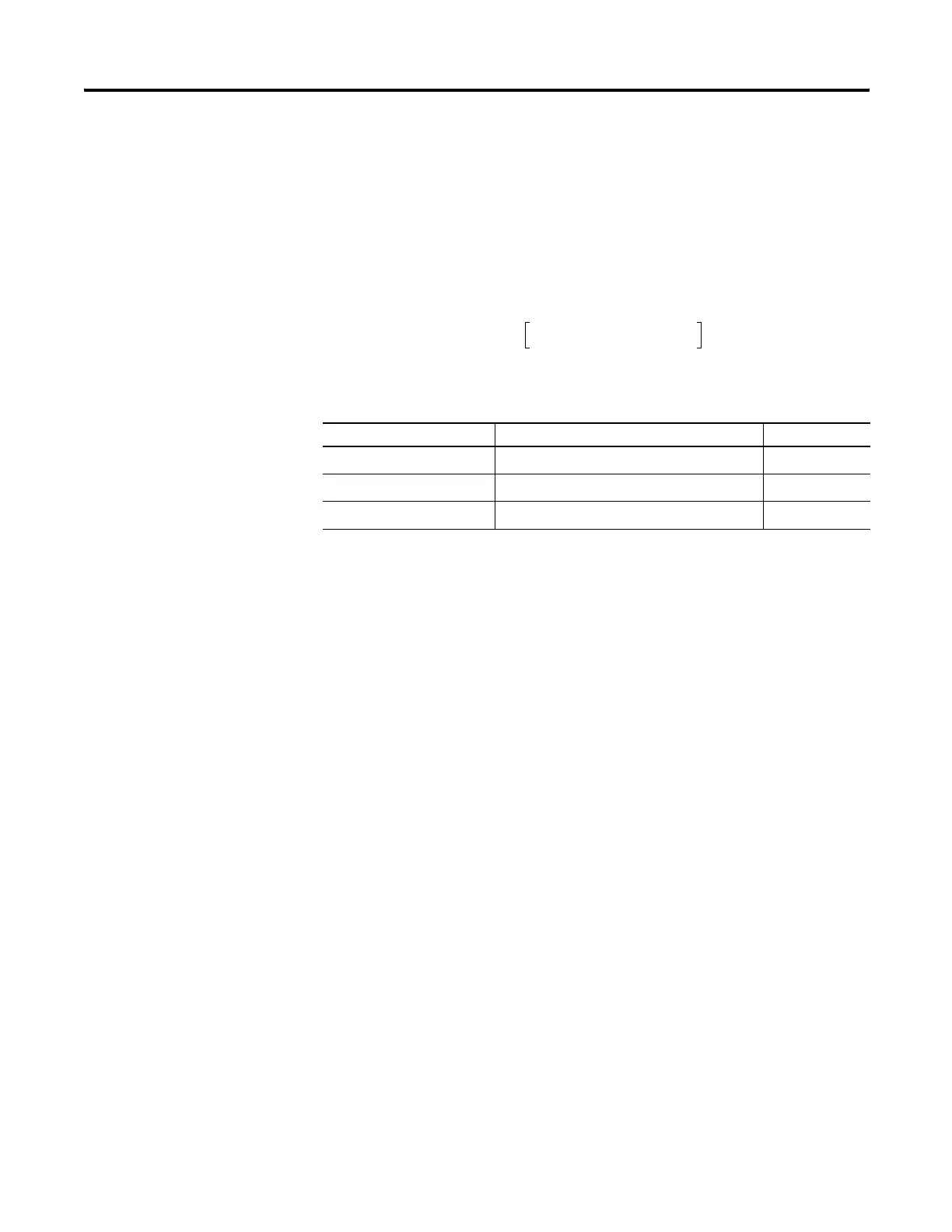

Term Range (Low to High) Reference

Controller Gain K

C

0.01 to 327.67 (dimensionless)

(1)

(1) Applies to MicroLogix 1100 PID range when Reset and Gain Range (RG) bit is set to 1. For more information on reset

and gain, see PLC 5 Gain Range (RG) on page 294.

Proportional

Reset Term 1/T

I

327.67 to 0.01 (minutes per repeat)

(1)

Integral

Rate Term T

D

0.01 to 327.67 (minutes)

(1)

Derivative

Output K

C

E()

1

T

I

---- -

E()td

∫

T

D

dPV()

dt

---------------

⋅++ bias+=

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Loading...

Loading...