PowerFlex 700 Adjustable Frequency AC Drive Quick Start 9

A variety of cable types are acceptable for drive installations. For many

installations, unshielded cable is adequate, provided it can be separated

from sensitive circuits. As an approximate guide, allow a spacing of 0.3

meters (1 foot) for every 10 meters (32.8 feet) of length. In all cases,

long parallel runs must be avoided. Do not use cable with an insulation

thickness less than or equal to 15 mils (0.4mm/0.015 in.). See

Table D.

Unshielded

THHN, THWN or similar wire is acceptable for drive installation in dry

environments provided adequate free air space and/or conduit fill rates

limits are provided. Do not use THHN or similarly coated wire in wet

areas. Any wire chosen must have a minimum insulation thickness of 15

Mils and should not have large variations in insulation concentricity.

Shielded/Armored Cable

Shielded cable is recommended if sensitive circuits or devices are

connected or mounted to the machinery driven by the motor. See

Table

D. For further information on acceptable and unacceptable cable types,

refer to “Power Wiring” in the PowerFlex 700 User Manual.

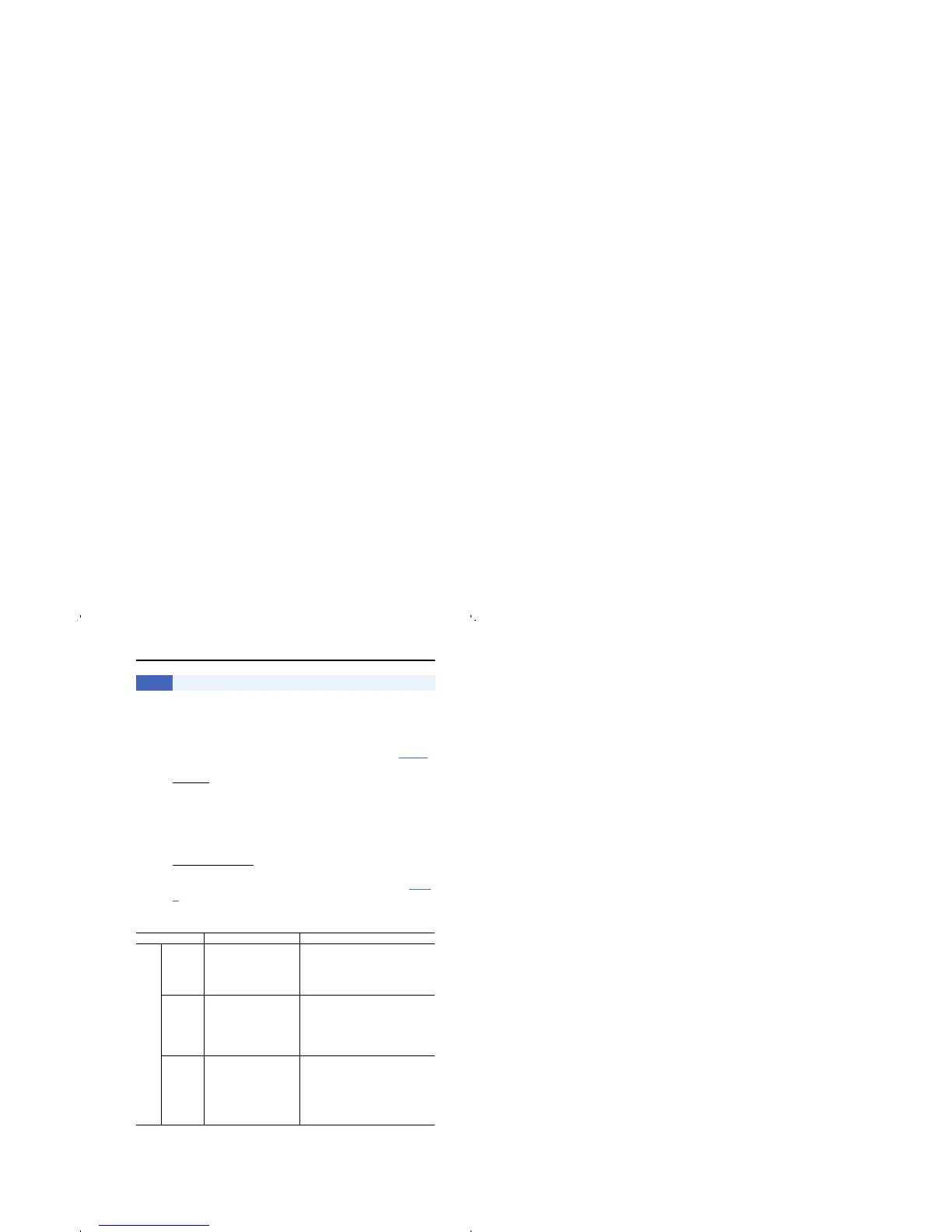

Table D Recommended Shielded Cable

Step 3 Power Wiring – Wire Recommendations

Type Wire Type(s) Description

Power Standard

(Option 1)

600V, 90°C (194°F)

XHHW2/RHW-2

Anixter B209500-B209507,

Belden 29501-29507, or

equivalent

• Four tinned copper conductors with XLP

insulation.

• Copper braid/aluminum foil combination

shield and tinned copper drain wire.

• PVC jacket.

Standard

(Option 2)

Tray rated 600V, 90° C (194° F)

RHH/RHW-2

Anixter OLF-7xxxxx or

equivalent

• Three tinned copper conductors with

XLPE insulation.

• 5 mil single helical copper tape (25%

overlap min.) with three bare copper

grounds in contact with shield.

• PVC jacket.

Class I & II;

Division I & II

Tray rated 600V, 90° C (194° F)

RHH/RHW-2

Anixter 7V-7xxxx-3G or

equivalent

• Three bare copper conductors with XLPE

insulation and impervious corrugated

continuously welded aluminum armor.

• Black sunlight resistant PVC jacket

overall.

• Three copper grounds on #10 AWG and

smaller.

Loading...

Loading...