16 Rockwell Automation Publication 750-IN020D-EN-P - May 2017

PowerFlex 755 IP00, NEMA/UL Open Type Drive

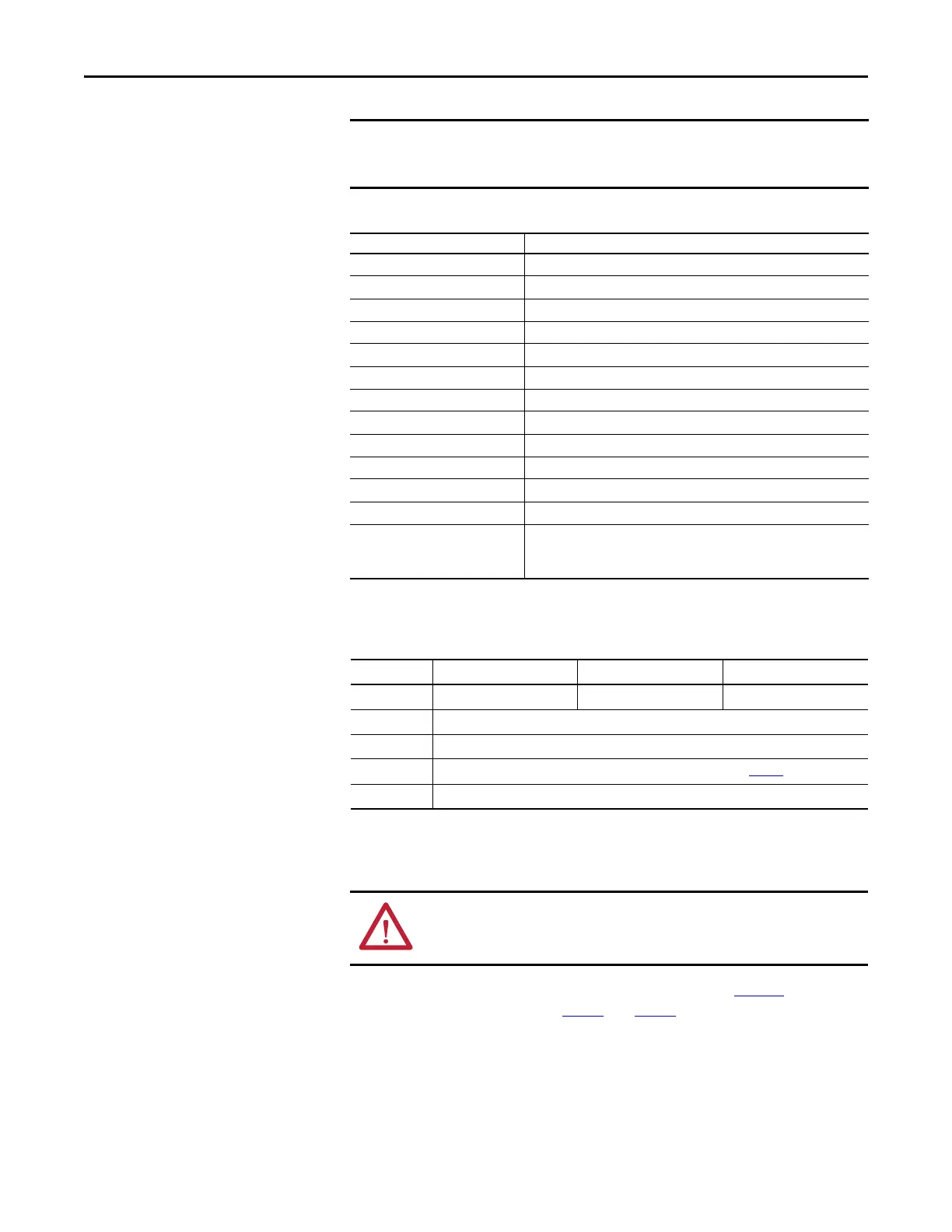

Installation Tools

This list covers the tools needed for drive installation.

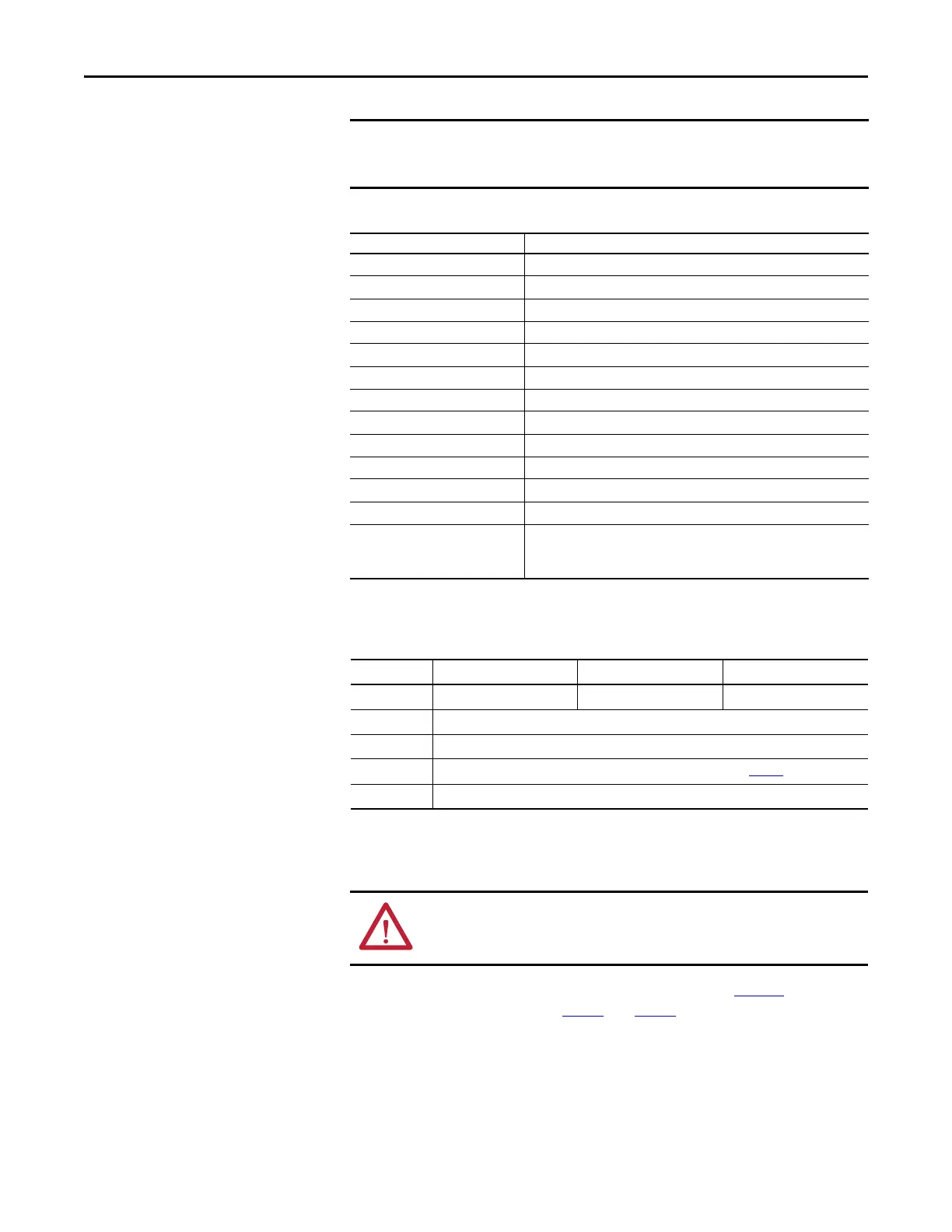

Enclosure Requirements

The following specifications must be met for proper installation.

Bus Bars

Power wiring is connected to the drive power terminals (see page 47) using the

Field Termination kits shown on page 6

and page 7 or fabricated using material

with the following specifications:

• Material: CDA 110 Copper

• Minimum Cross Section: 80.7mm

2

(0.125

in.

2

) per each 100 A of drive

rating.

Care must be taken to ensure that tools and/or hardware components do not fall into

open drive assemblies. Do not energize the drive unless all loose tools and/or hardware

components have been removed from the drive assemblies and enclosure.

Tool Description Details

ESD-protected place of work Working surface, Floor covering, seat and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Allen socket wrench 5 mm

Allen socket wrench extension 254 mm (10 in.)

Flat nose screw driver 5 mm (0.19 in.), 6.4 mm (0.25 in.), 9.5 mm (0.375 in.), #1, #2

Hexalobular screw driver/bit #15, #20, #25, #40, #45

Hexagonal socket wrench 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Combination wrench 10 mm, 17 mm

Phillips screw driver/bit #2, 492-C

Pozidriv #2

Torque wrench 1...12 N•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)

Roll-out cart 20-750-CART1-F8

Note: The roll-out cart is required to remove the drive assembly from the

enclosure.

Frame 8Frame 9Frame 10

Width 800 mm (31.5 in.) min. 1600 mm (63.0 in.) min. 2400 mm (94.5 in.) min.

Depth 600 mm (23.6 in.) min.

Height 2200 mm (86.6 in.) min.

Weight Enclosure must be able to support the total equipment weight stated on page 36

.

Construction According to EN60439-1

ATTENTION: To guard against drive damage, DO NOT connect power wires

directly to the drive power terminals. Power wiring must be connected to bus

bars which are fastened to the drive power terminals.

Loading...

Loading...