12 SLC 500™ RTD/Resistance Input Module

Publication 1746-IN012B-EN-P - May 2001

There are several ways to insure that the lead values match as closely as possible.

They are as follows:

• Keep lead resistance as small as possible and less than 25Ω.

• Use quality cable that has a small tolerance impedance rating.

• Use a heavy-gauge lead wire which has less resistance per foot.

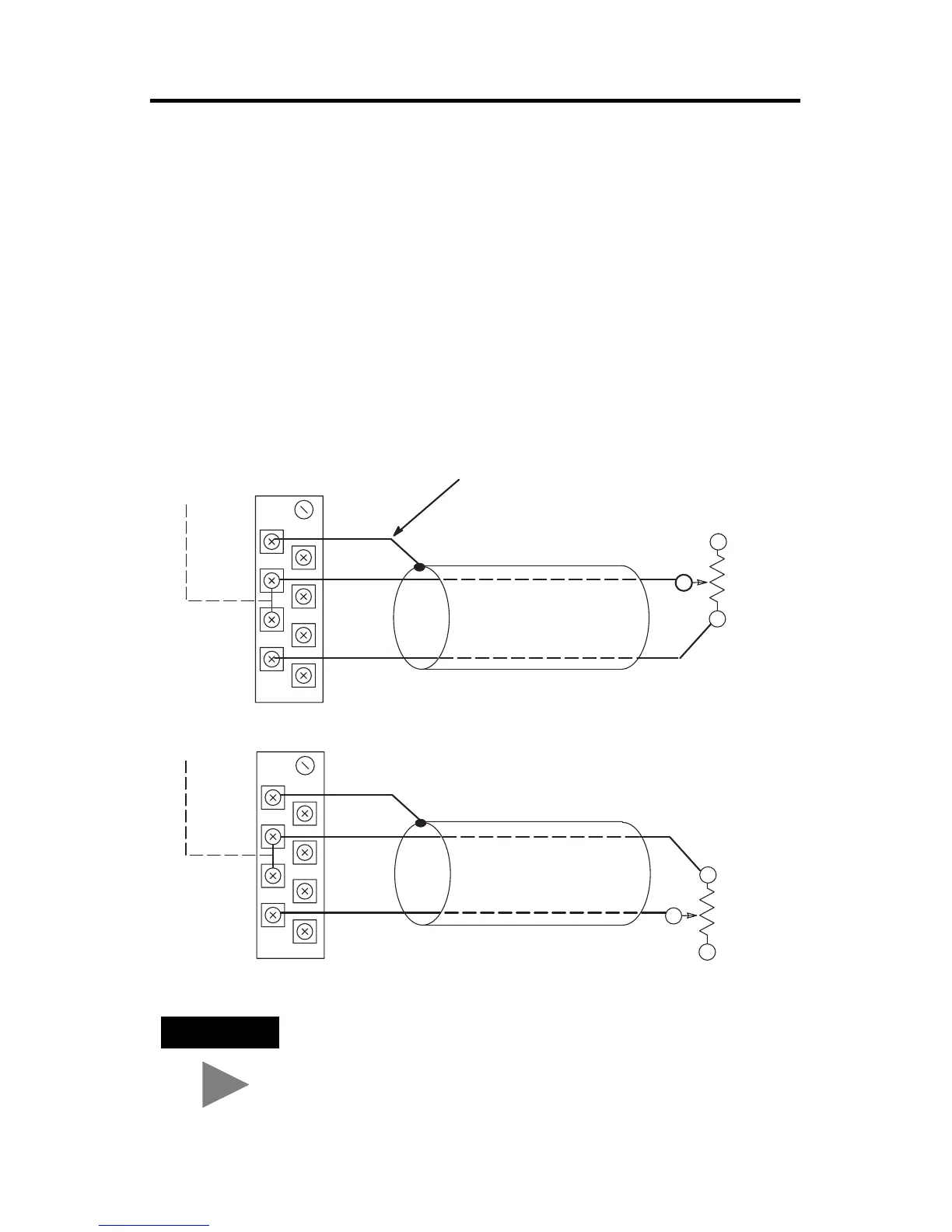

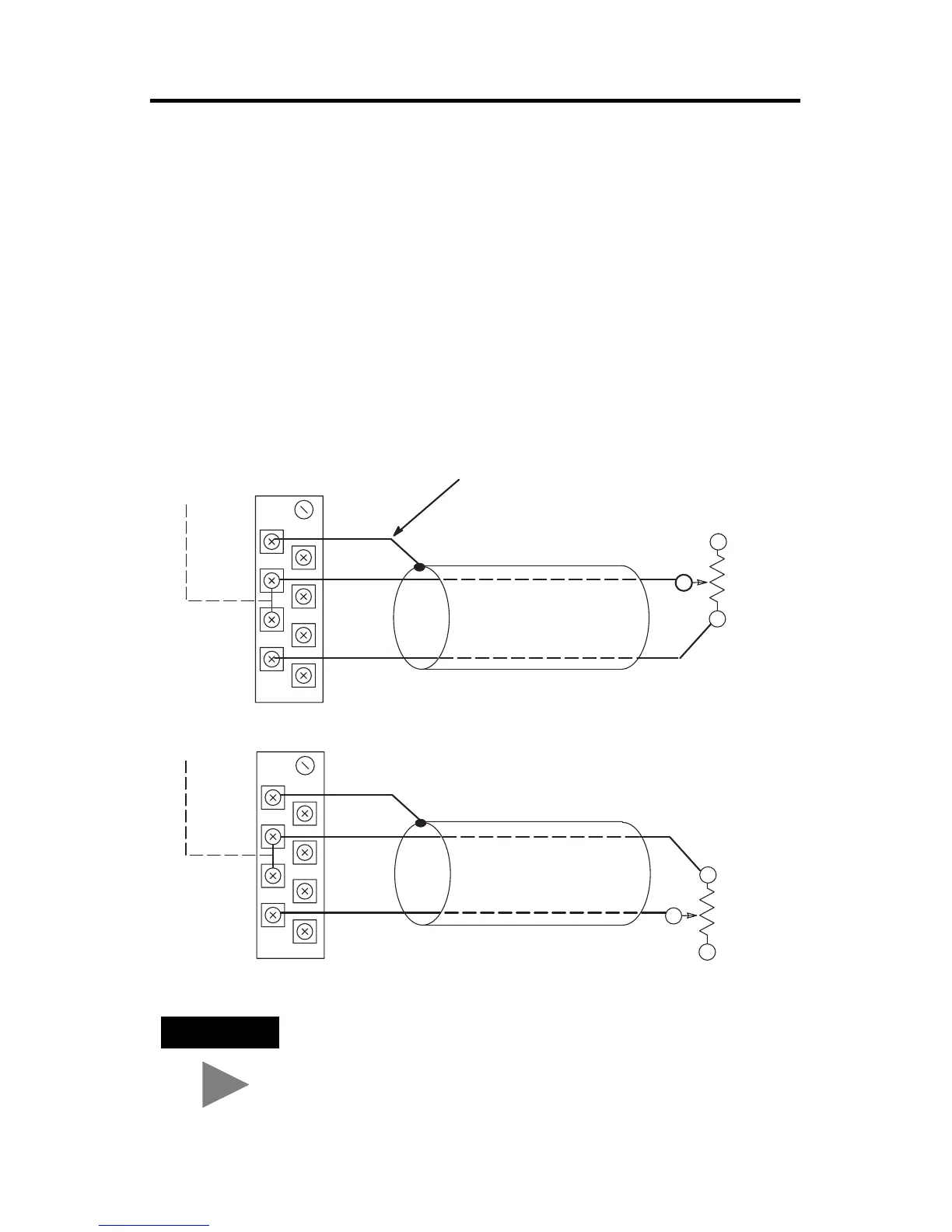

Wiring Resistance Devices (Potentiometers) to the NR4 Module

Potentiometer wiring requires the same type of cable as that for the RTD described

on page 9. Potentiometers can be connected to the RTD module as a 2-wire

interconnection or a 3-wire interconnection as shown on the following pages.

TIP

Potentiometer wiper arm can be connected to either the RTD

or Return terminal, depending on whether you want

increasing or decreasing resistance.

Cable Shield

Potentiometer

RTD

Return

Belden #9501 Shielded Cable

Add Jumper

Shield

CH 0 RTD

CH 0 Sense

CH 0 Return

Potentiometer

RTD

Return

Belden #9501 Shielded Cable

Add Jumper

Shield

CH 0 RTD

CH 0 Sense

CH 0 Return

Loading...

Loading...