AM81687-A

Original Instructions – English

23

Do not over tighten the bottom blade – the cylinder should be able to spin freely

If you are still unable to cleanly cut paper, inspect the bottom blade and cylinder. If they appear,

rounded, damaged or excessively worn they may need to be reground or replaced. New bottom

blades should always be reground attached to the bottom blade carrier. For bottom blade grinding

angles see the section below.

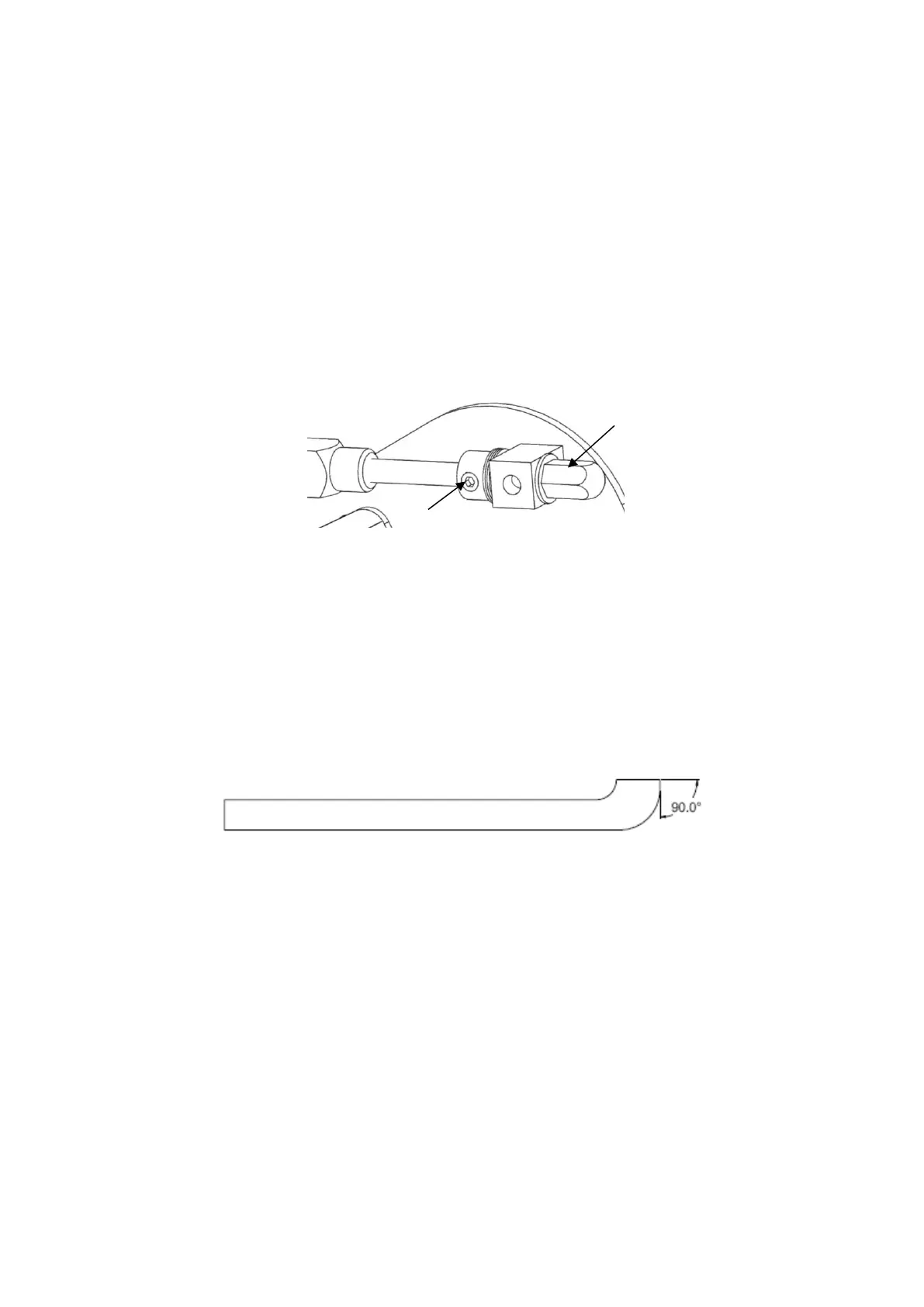

The bottom blade adjusters can sometimes become very tight and may be hard to turn. If this is the

case:

1) Slacken off the grub screw on the collar

2) Rotate the adjuster anti-clockwise 1/8

th

of a turn

3) Tighten the grub screw

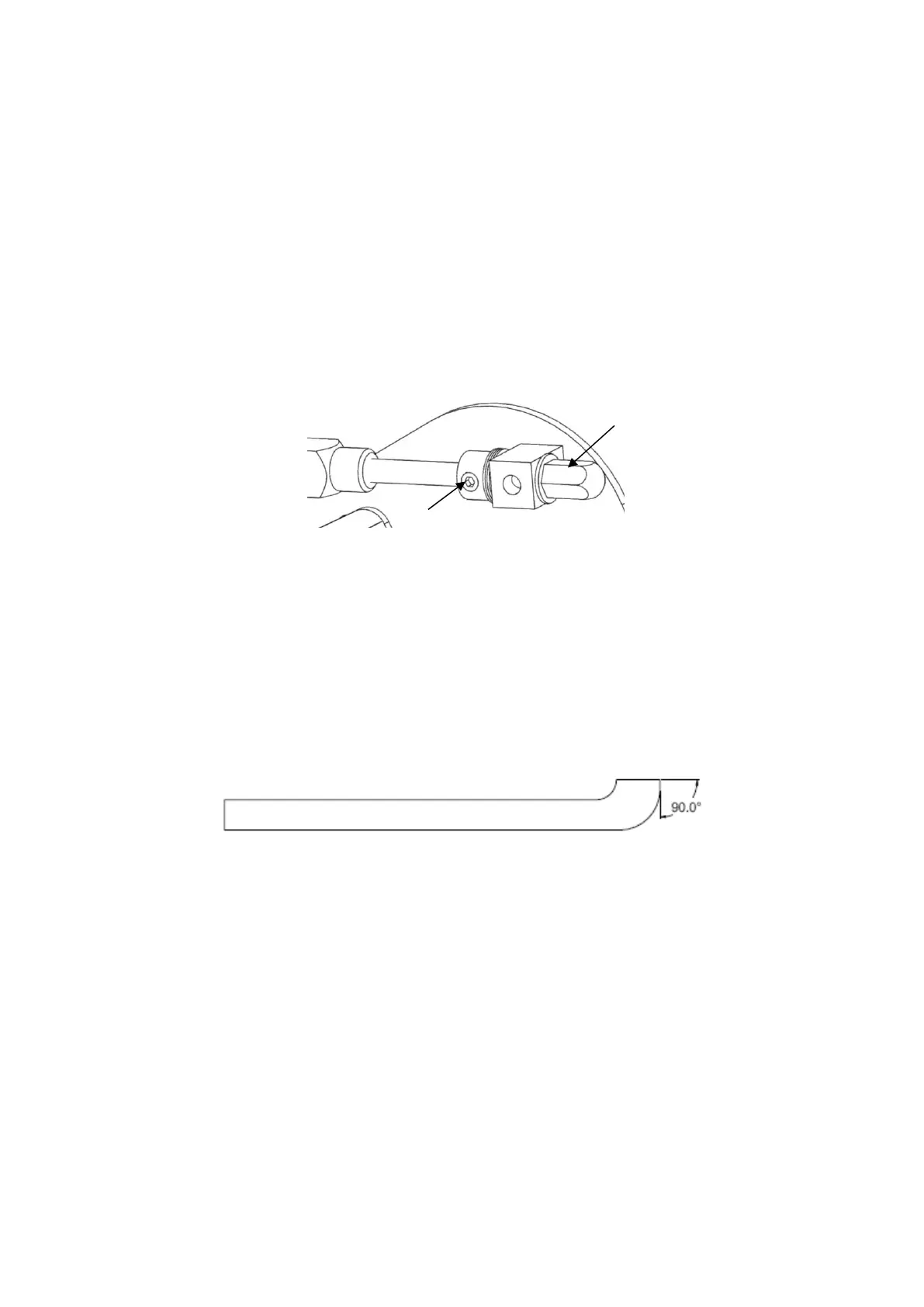

Bottom blade grinding angles

For cylinder cutting cartridges only. The cutting performance of the mower is highly dependent on

the condition of both the cylinder and bottom blade. Poorly maintained parts will lead to a poor

quality of cut.

Newly fitted bottom blades will need to be ground when bolted to the blade carrier to ensure a

perfectly flat cutting edge.

It is advisable that grinding/reconditioning is carried out by an authorised Allett dealer to the angles

shown below.

Inspection of safety critical components

The below parts are critical to the safe operation of your lawnmower, before each use check that:

When the park brake is engaged the mower cannot move.

The guards, deflectors and the grass box are in good condition and secured in place.

When the bale bars are released the cylinder/cartridge and land roll drive stop immediately.

Loading...

Loading...