b. Abnormal Conditions. Transmission fluid must be changed whenever there

is evidence of dirt in the fluid or the fluid is discolored, which indicates a high

temperature condition. Fluid analysis will also reveal a high temperature condition.

Local conditions, severity of operation, or duty cycle may require more or less

frequent fluid or filter changes.

c. Fluid Analysis. Transmissions used in high cycle rate applications should

have a fluid analysis performed to be sure of the proper change interval.

Transmission protection and fluid change intervals can be optimized by monitoring

fluid oxidation according to the tests and limits shown in Table 2–7. Consult your

local telephone directory for fluid analysis firms. To be sure of consistent and

accurate fluid analysis, use only one fluid analysis firm. Refer to the Technician’s

Guide for Automatic Transmission Fluid, GN2055EN, for additional information.

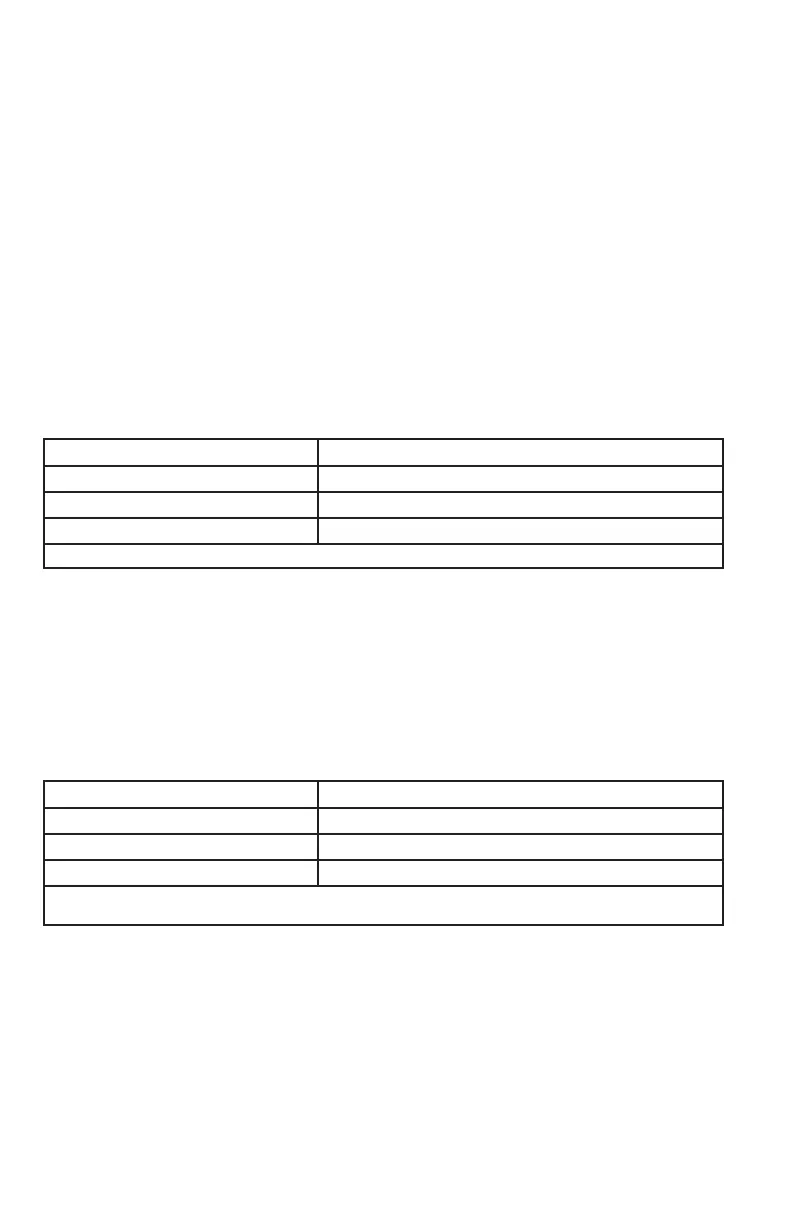

Table 2–7. Fluid Oxidation Measurement Limits

Test Limit

Viscosity ±25% change from new fluid

Total Acid Number +3.0

* change from new fluid

Solids 2 percent by volume maximum

* mg of potassium hydroxide (KOH) to neutralize a gram of fluid.

2–7. TRANSMISSION FLUID CONTAMINATION

a. Fluid Examination. The presence of fluid contamination in an automatic

transmission can be detrimental to continued operation. A normal amount of

condensation will appear in the fluid during operation. At each fluid change,

examine the drained fluid for evidence of dirt or water. Contamination limits are

shown in Table 2–8.

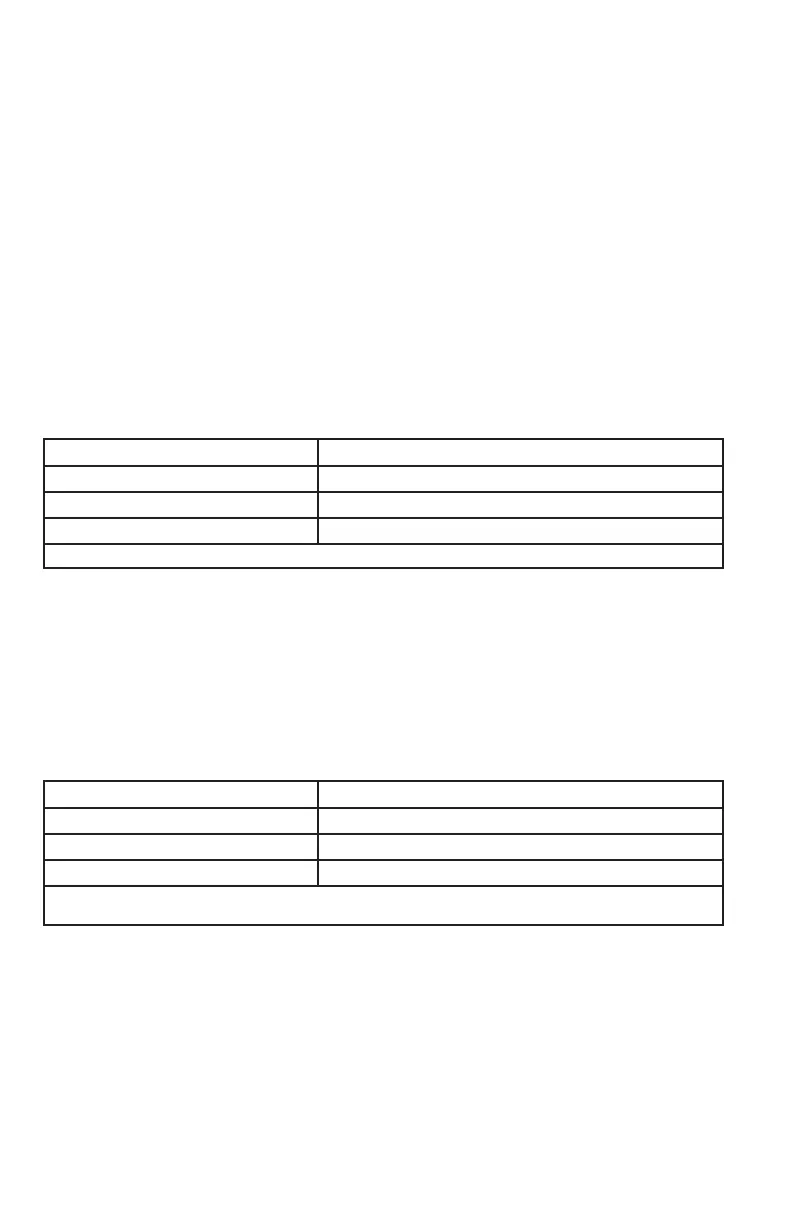

Contaminant Limit

Water 0.2% maximum

Glycol No trace allowed

Alien fluids

* If detected, change transmission fluid

* Any fluid not included on the Allison Approved Fluid List. The Approved Fluids Lists may be

found at the Allison Transmission website, www.allisontransmission.com.

b. Monitoring Wear. Absolute maximum values cannot be applied to wear

metals of an automatic transmission due to the many variables present that affect

concentration limits. Wear metal analysis results must be evaluated using a

trendline approach.

A trendline approach plots the concentration level of each wear metal over a

period of time. A minimum of four data points for each metal is required to

establish a trendline. A line of “best fit” drawn through the plotted points is

32

Loading...

Loading...