4–1. INSPECTING INPUT COMPONENTS

a. Bolt Holes. Inspect all bolt holes on the front of the transmission and rear of

the engine that are used in connecting the transmission to the engine. The threads

must be undamaged and the holes free of chips or foreign material.

b. Pilot Boss. Inspect the pilot boss (at the center of the flywheel) for damage or

raised metal that prevents free entry into the crankshaft hub (or adapter).

c. Starter Ring Gear. Inspect the starter ring gear for excessive wear or

damage.

d. Transmission Mounting Flange. Inspect the transmission mounting flange

for raised metal, dirt, or if used, pieces of gasket material.

e. Transmission-to-Engine Mounting. Inspect the transmission-to-engine

mounting flange for raised metal, burrs, or pieces of gasket material (if used).

Remove any of these defects. Inspect the threaded holes for damaged threads.

4–2. INSTALLING OUTPUT FLANGE OR YOKE

a. Output Oil Seal. Inspect the output oil seal for leaks or damage. Refer to

Customer Service Section, Table 8–1, for the appropriate service manual for

replacement instructions. If not replacing the oil seal, lubricate it with

high-temperature grease or transmission fluid.

CAUTION: DO NOT attempt to polish the oil seal contact surface on

the flange or yoke. Scratches or machine-type lead can cause the seal to

leak.

b. Inspect Flange or Yoke. Inspect flange or yoke for damage or wear. The oil

seal contact surface must be smooth and regular to prevent oil leaking past the

seal. Rotate the flange after installation to be sure that the flange isn’t binding.

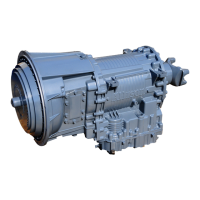

TRANSMISSION

PREPARATION

Section IV

55

Loading...

Loading...