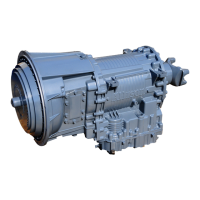

5–1. ENGINE, TRANSMISSION ADAPTATION REQUIREMENTS

You must make sure a new transmission installation can be adapted to the

vehicle’s engine. Use the measurements described in this section for correct

transmission-to-engine adaptation. Refer to Figure 5–1 or Figure 5–2 and/or

AS67–020. Typical arrangement of adaptation components is shown in Figure 5–4.

a. Measuring Equipment. The following measuring equipment is required:

• 600 mm (24 inch) precision caliper

• 50–100 mm (2–4 inch) telescoping gauge

• 25–76 mm (1–3 inch) outside micrometer

• Dial indicator and mounting attachments—base, posts, and clamps

• 0–150 mm (0–6 inch) depth micrometer

b. Flywheel Housing Pilot Bore Diameter. The flywheel housing pilot bore

diameter must measure:

• 3000 Product Family—447.68–447.81 mm (17.625–17.630 inches).

• 4000 Product Family—511.18–511.30 mm (20.125–20.130 inches).

c. Flywheel Housing Bore Runout. Flywheel housing bore runout cannot

exceed 0.51 mm (0.020 inch) TIR.

d. Flywheel Housing Face Squareness. The flywheel housing face cannot be

out-of-square more than 0.51 mm (0.020 inch) TIR.

e. Crankshaft Hub Pilot or Adapter Diameter. The crankshaft hub pilot or hub

adapter pilot diameter must measure between 50.94–50.99 mm

(2.006–2.008 inches).

f. Crankshaft Hub Pilot or Adapter Squareness. The crankshaft hub or hub

adapter cannot be out-of-square more than 0.13 mm (0.005 inch) TIR.

g. Crankshaft Hub Pilot or Adapter Concentricity. The crankshaft hub pilot

or the hub adapter pilot concentricity cannot exceed 0.13 mm (0.005 inch) TIR.

PREPARING VEHICLE

FOR TRANSMISSION

INSTALLATION

Section V

59

Loading...

Loading...