Copyright © 1998 General Motors Corp. 6–43

DIAGNOSTIC CODES

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

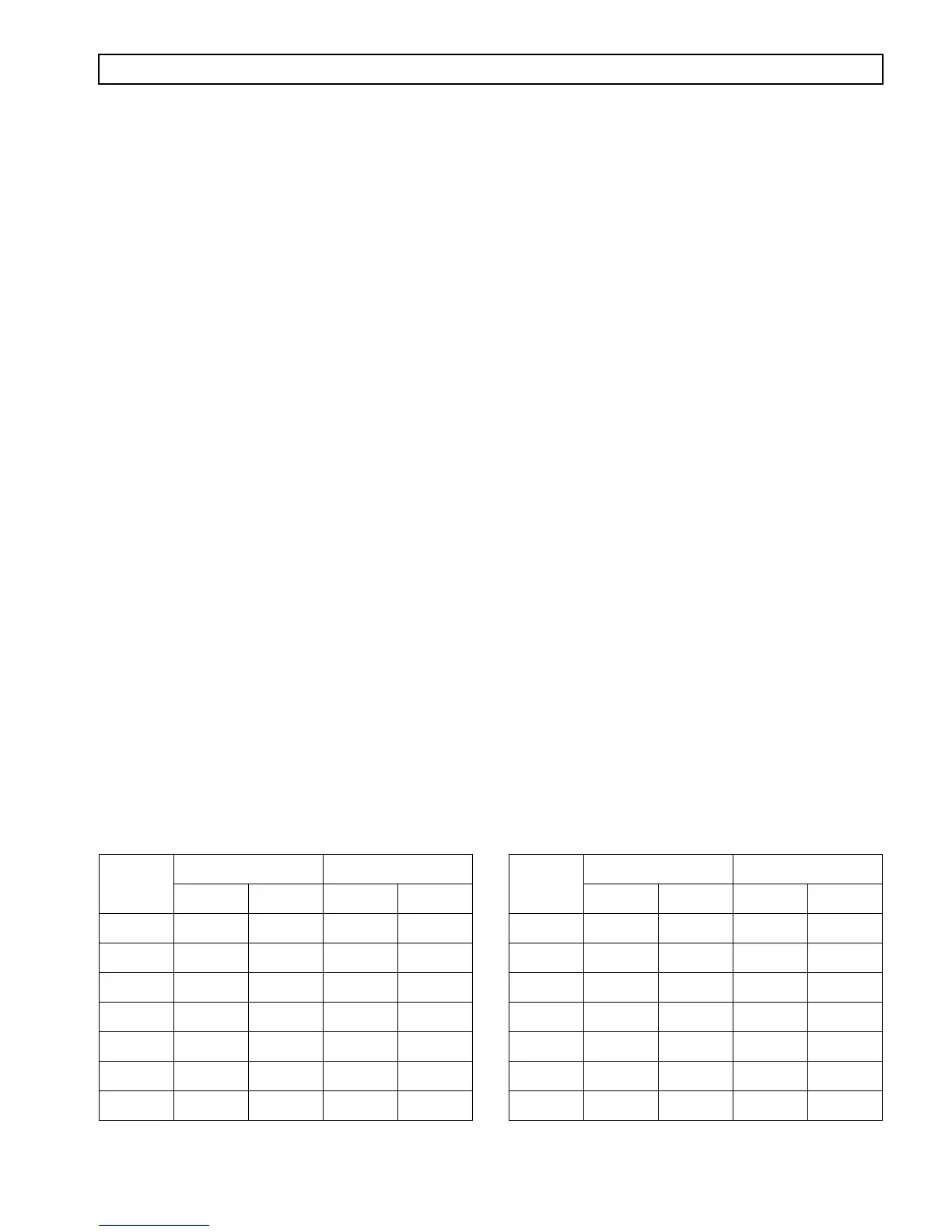

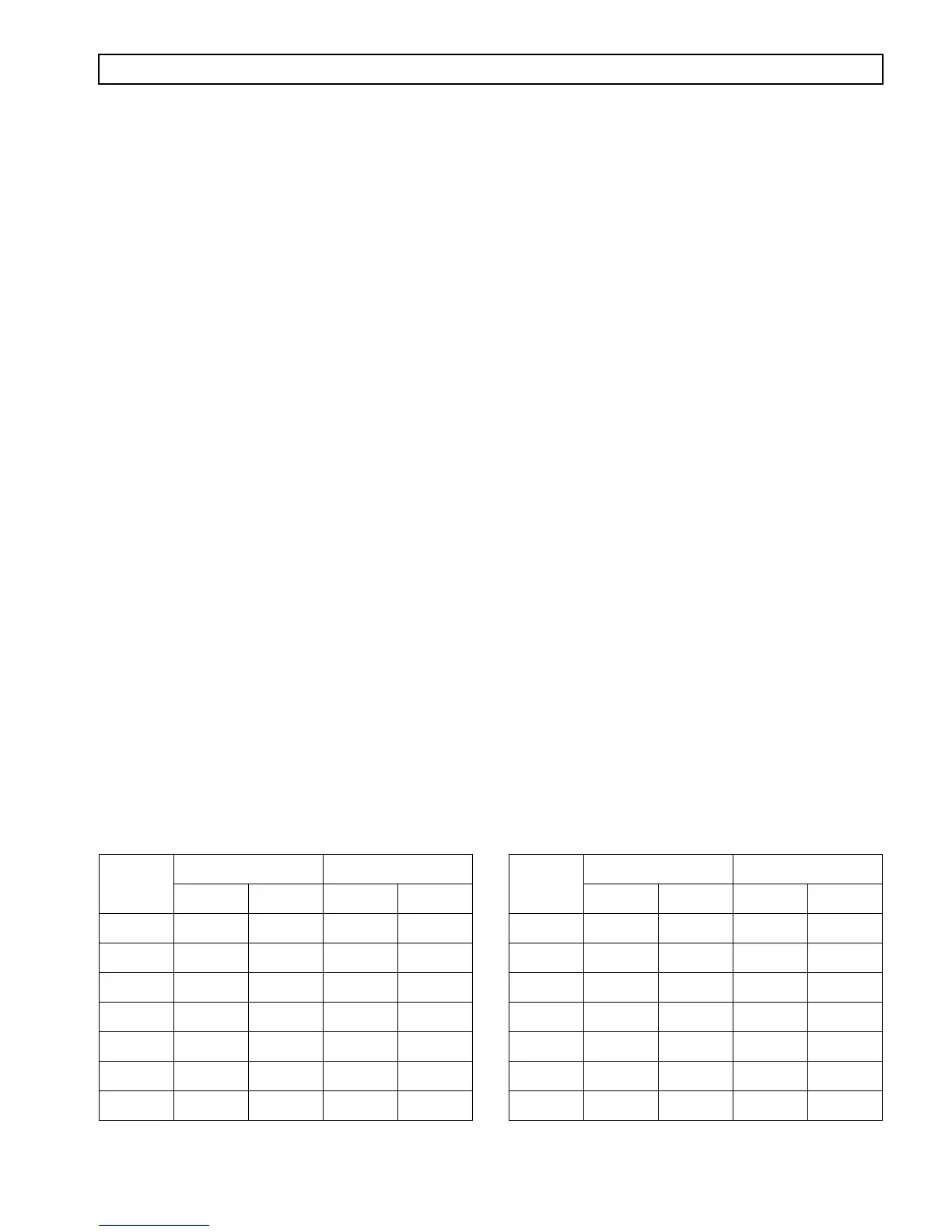

Table 6–5. External Hydraulic Circuit Characteristics

Non-Retarder, PTO, 93°C (200°F) Sump Temperature

HD/B 500

B. Code 24 23:

1. Install temperature gauges for transmission temperature and engine water temperature. Drive the

vehicle. Verify the code can be reproduced and verify the reading shown on the diagnostic tool.

Observe the gauges and check for hot fluid when the code is produced.

2. If the fluid is not hot when the code is produced, remove the connectors at the ECU and the

transmission. Check the fluid temperature sensor wiring for opens, shorts, and shorts-to-ground.

Compare the resistance readings of the sensor and the actual temperature as shown on the gauge

with Figure 6–12 on previous page. If wiring problems or a great difference between temperature

and resistance compared with the chart are found, drain the fluid, remove the control module, and

replace the temperature sensor (refer to the Service Manual for the transmission being checked). If

wiring problems are found, repair or replace as necessary.

3. If the fluid is hot when the code is produced, observe the gauges to see if the engine became hot

before the transmission. If the engine cooling system is overheating and heating the transmission,

the problem is with the engine or its cooling system.

4. If the transmission became hot before the engine, allow the vehicle to idle for 3–5 minutes and

check the transmission fluid level. Correct the fluid level if necessary.

5. Attach pressure gauges to the cooling system (from a “to cooler” connection to a point after the

cooling circuit filter) and check for pressure drop problems. If pressure drop is excessive (refer to

Table 6–5), check for a plugged cooler filter, collapsed lines, obstructions, etc.

6. If the fluid level is correct and the cooling circuits satisfactory, drain the fluid, remove the control

module, and inspect for damaged valve body gaskets. Replace any damaged gaskets (refer to the

appropriate transmission Service Manual).

7. If no problems are found in the control module area, remove the transmission and

disassemble, inspecting for causes of overheating (stuck stator, plugged orifices, dragging

clutches, etc.). (See the Service Manual for the transmission being checked.)

CODE 24 XX — SUMP FLUID TEMPERATURE (Figures 6–10, 6–11)

CONVERTER OPERATION

MAXIMUM

COOLER FLOW

Input

rpm

Flow Pressure Drop

L/s gpm kPa psi

600 0.22 3.4 0 0

900 0.38 6.1 0 0

1200 0.55 8.7 0 0

1500 0.80 12.7 0 0

1800 1.03 16.4 0 0

2100 1.13 18.0 0 0

2300 1.20 19.0 0 0

CONVERTER OPERATION

MAXIMUM ALLOWABLE

PRESSURE DROP

Input

rpm

Flow Pressure Drop

L/s gpm kPa psi

600 0.20 3.2 31 4.5

900 0.37 5.8 63 9.1

1200 0.55 8.7 108 15.7

1500 0.77 12.2 167 24.2

1800 0.92 14.5 213 30.9

2100 0.97 15.3 238 34.5

2300 1.00 15.9 250 36.3

Loading...

Loading...