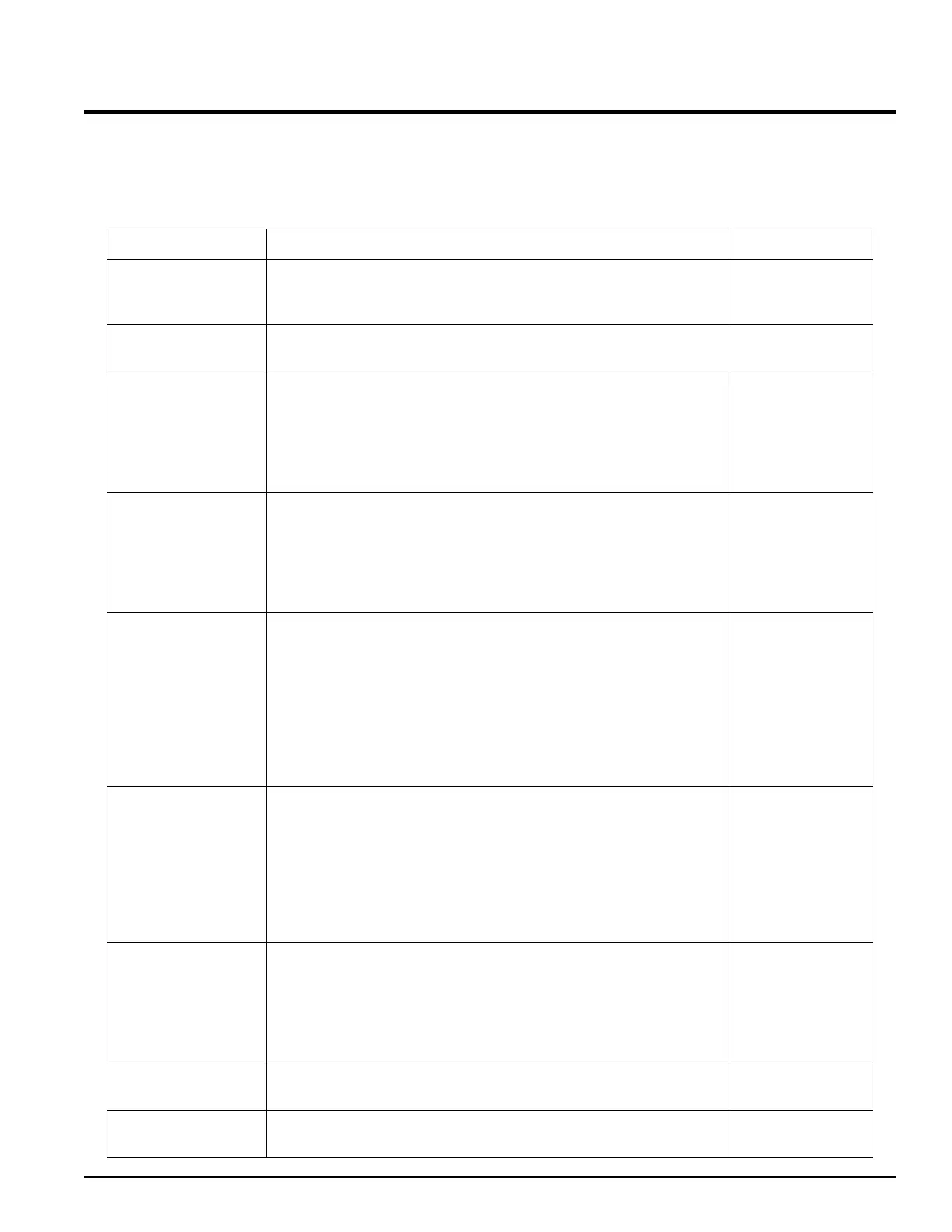

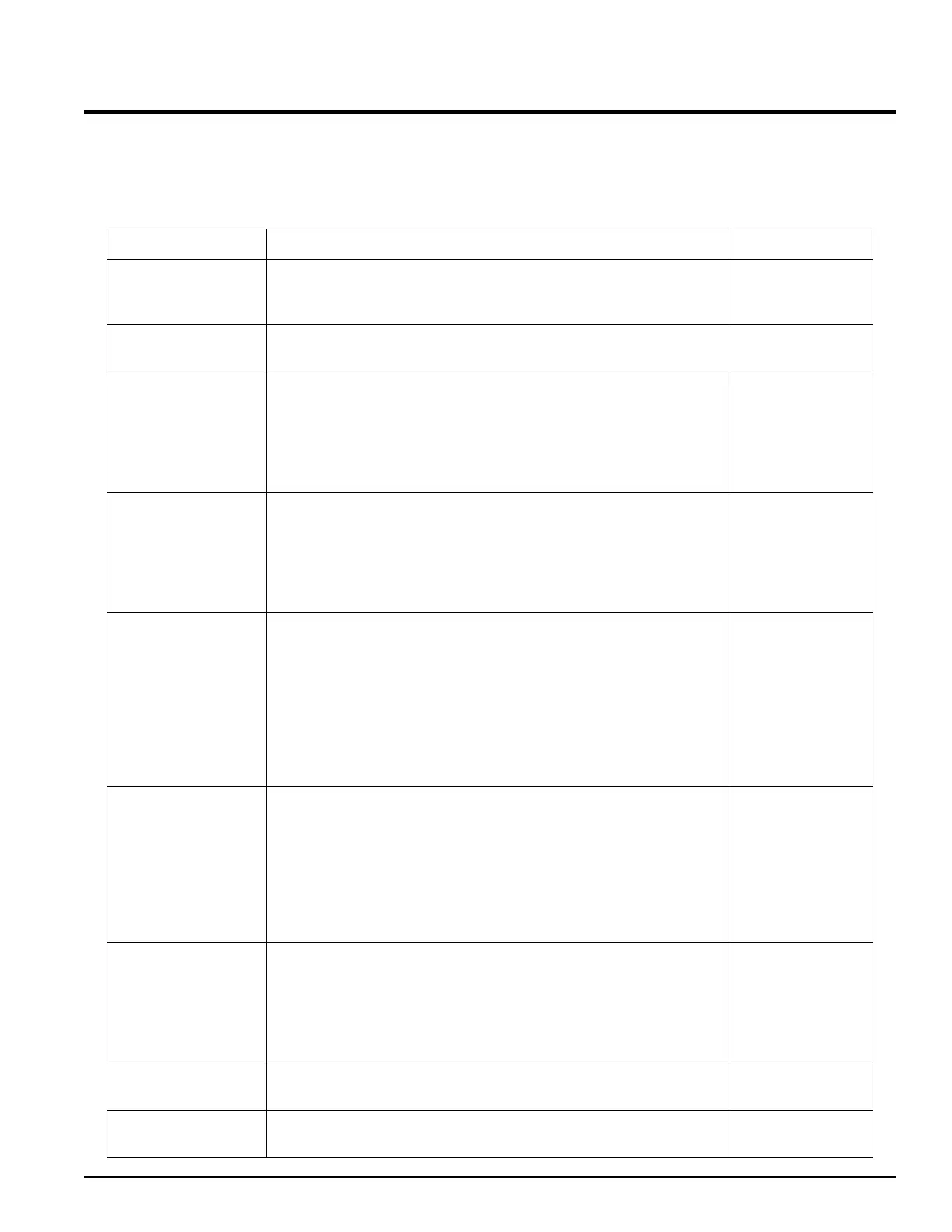

EXAMPLE COMMANDS

Below are the MODBUS registers for common settings. The complete list of registers

are located in Appendix K.

715

Current limit when the process is Below the Current limit Set

Point temperature setting.

Current limit Below

[IL`b]

714

Current limit when the process is Above the Current limit Set

Point temperature setting.

Current limit Above

[IL`A]

713Set Point temperature at which the Current limits are referenced.

This is only appropriate when the settings of [IL`A] and

[IL`b] are not identically set. If the process temperature goes

“A”bove this set point, then the [IL`A] current limit will be in

effect. If the process temperature goes “B”elow this set point,

then the [IL`b] current limit will be in effect.

Current limit Set

Point (temperature)

[ILSP]

606Digits after the decimal point. Use this to determine where to put

the decimal point after reading a register variable that returns a

temperature setting.

Example:

Read register 300 (“R300,1”) and get “9999” and reading register

606 yields a “2”. Therefore, the reading from register 300 is

really “99.99” with the decimal point 2 digits from the right.

Decimal Point

340,341Alarm 3 low & Alarm 3 high.

If the process temperature should go below A3lo the output will

be turned off.

If the process temperature should go above A3hi the output will

be turned off.

DO NOT turn off the Alarms by disabling the Out3 setting via

the front panel! Rather set the alarms outside the desired

temperature range to avoid an alarm and turning off the

output to the TEC.

Temperature Alarms

[a3lo] and

[a3hi]

510,511,513Heating parameters P,I,& D

Proportional Band 2

Integral Term 2

Derivative Term 2

When HEATING these parameters will determine the control

stability.

PID2

[Pb`2]

[It`2]

[dE`2]

500,501,503Cooling parameters P,I,& D

Proportional Band 1

Integral Term 1

Derivative Term 1

When COOLING these parameters will determine the control

stability.

PID1

[Pb`1]

[It`1]

[dE`1]

300Desired temperature

READ/WRITE. -1999 to 9999 limited to input range.

Set point

100Actual temperature

READ ONLY. -1999 to 9999 limited to input range. (i.e.

Thermistor 0 to 9999)

Process

Register(s)DescriptionName

ALPHA OMEGA INSTRUMENTS CORP. Instruction Manual

Series 800/850 Thermoelectric Cooler Controller Page 87

Loading...

Loading...