25

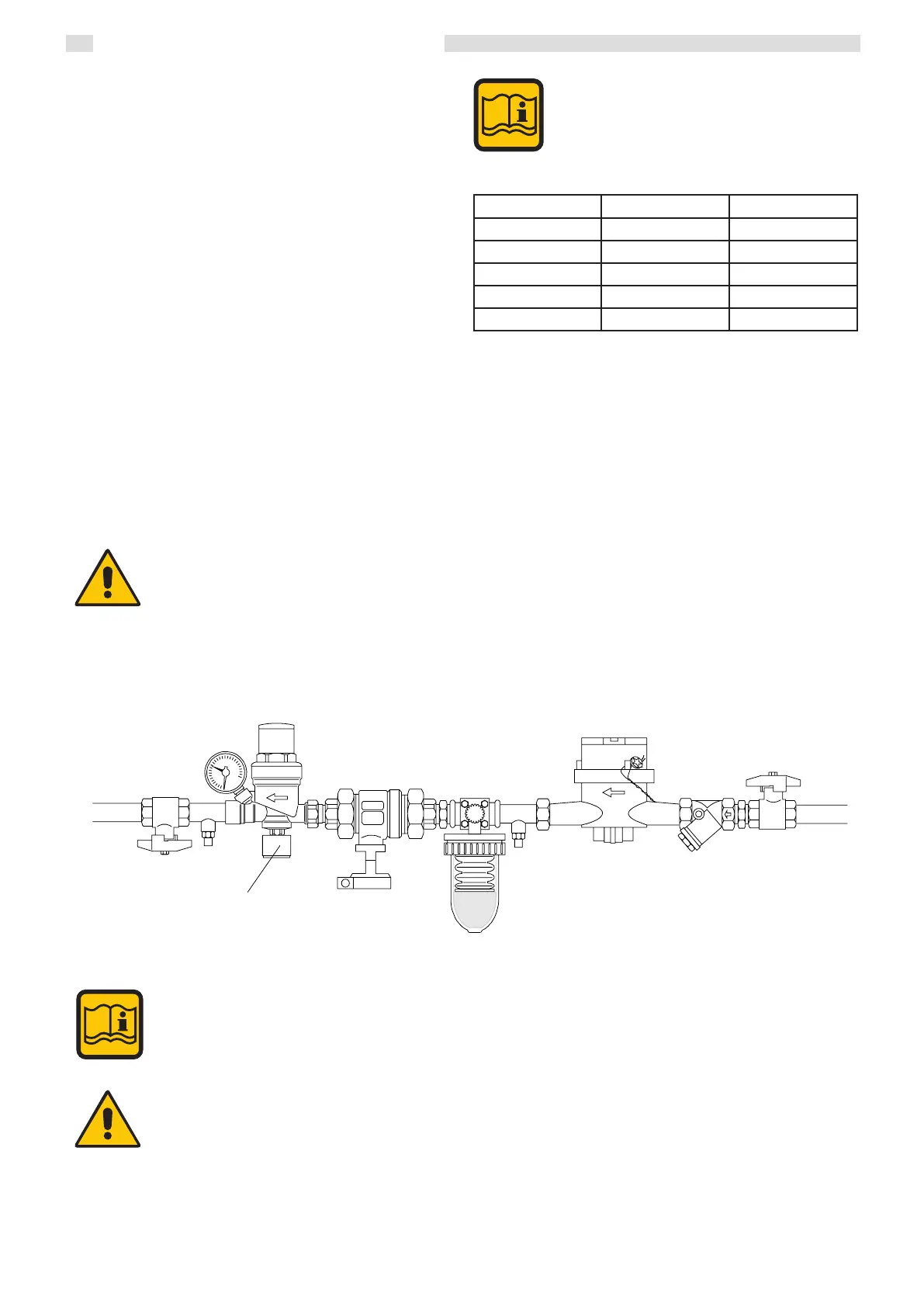

GRUPPO DI

CARICAMENTO

3.11 SYSTEM FILLING AND EMPTYING

Once all of the connections for the system have been

set up, it is possible to ll the circuit.

To ll the system it is possible to set up a loading valve

on the system's return pipe.

EXAMPLE OF SYSTEM LOADING UNIT

A load cock must be provided on the central heating

circuit in order to ll the system, or use the optional

accessories.

e boiler is equipped with its own draining valve, 14.

is valve must never be used to empty the system,

since all of the dirt contained in the system may ac-

cumulate in the boiler, jeopardising smooth operation.

erefore, before using the draining valve, make sure

that the system’s interception cock situated under the

pump has been closed. e system must be equipped

with its own emptying valve, of a suitable size for the

ow rate of the system.

LOADING

UNIT

Instructions for the installer

3.15 CONNECTING THE FLUE

Condensing boilers produce ue products at very low temperatures,

generally below 84°C (approx). It is therefore necessary that the ue

is impervious to the condensate produced and built with suitable

corrosion-resistant materials.

e connecting joints must be sealed and equipped with suitable gaskets

to stop condensation from leaking out and air from getting in.

In terms of ue section and height, it is necessary to refer to national

and local regulations in force.

Refer to regulations in force for sizing.

In order to avoid the formation of ice during operation, the temperature

of the inside wall at every point in the ue system, for its entire length,

must not drop below 0°C.

e ue system must comply with local and national regulations.

e ue system must be built using materials that are resistant to the

combustion products, typically 316 certied stainless steel or plastic

materials, such as PVDF (polyvinyldimethyluoride) or PPS (simple

translucent polypropylene) or aluminium or other materials with

the same features, in observance of regulation in force.

e supplier is excluded from any contractual and

extra-contractual liability for damage caused by

errors in installation and use due to failure to observe

the instructions provided by the manufacturer.

Model Modules Flue spigot diameter

440 4 250

550 5 250

660 6 300

770 7 300

900 8 300

Loading...

Loading...