37

All of the instructions below are provided for the

exclusive use of authorised assistance personnel.

3.13 BURNER ADJUSTMENT

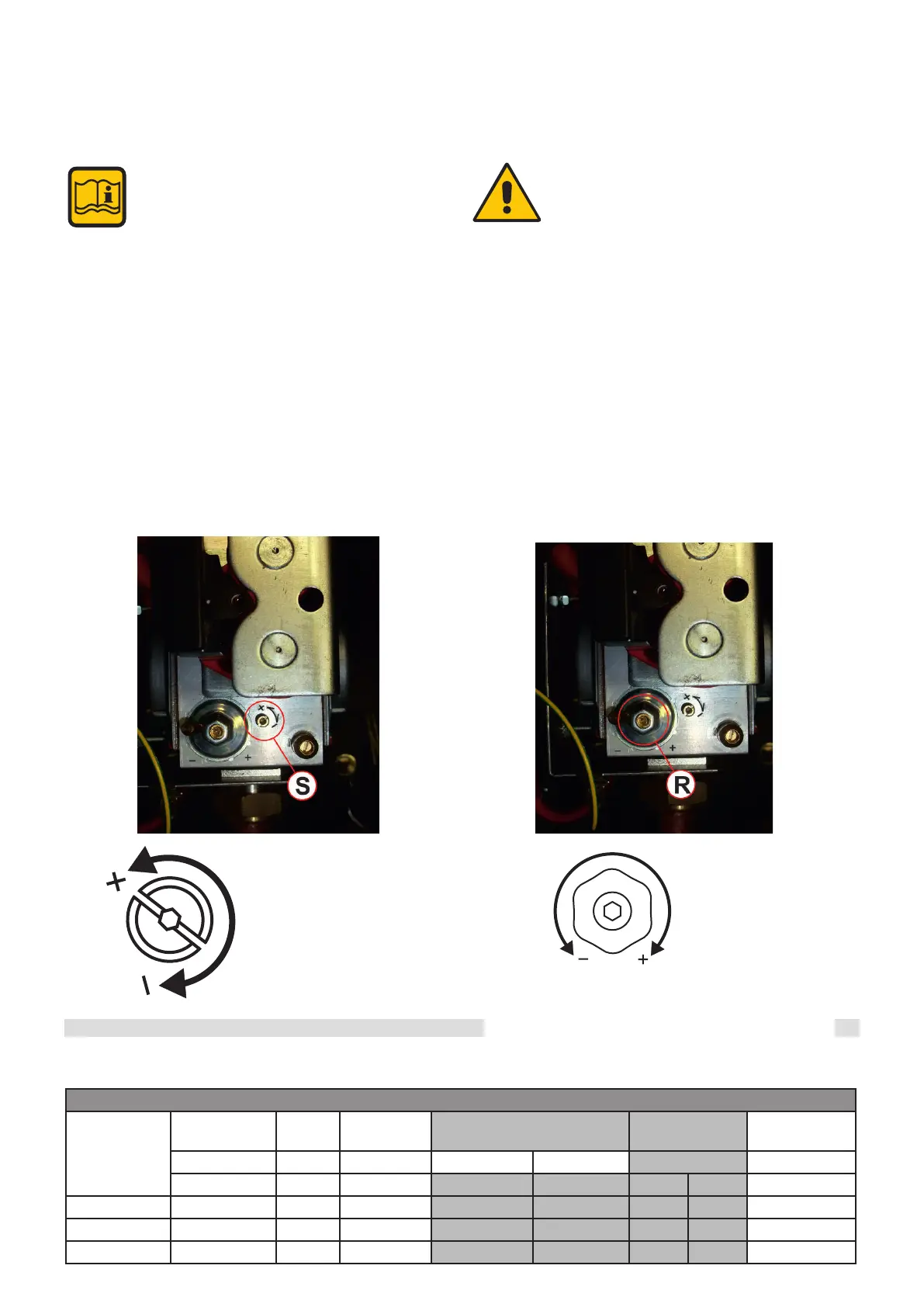

(S)

MAXIMUM POWER

ADJUSTING SCREW

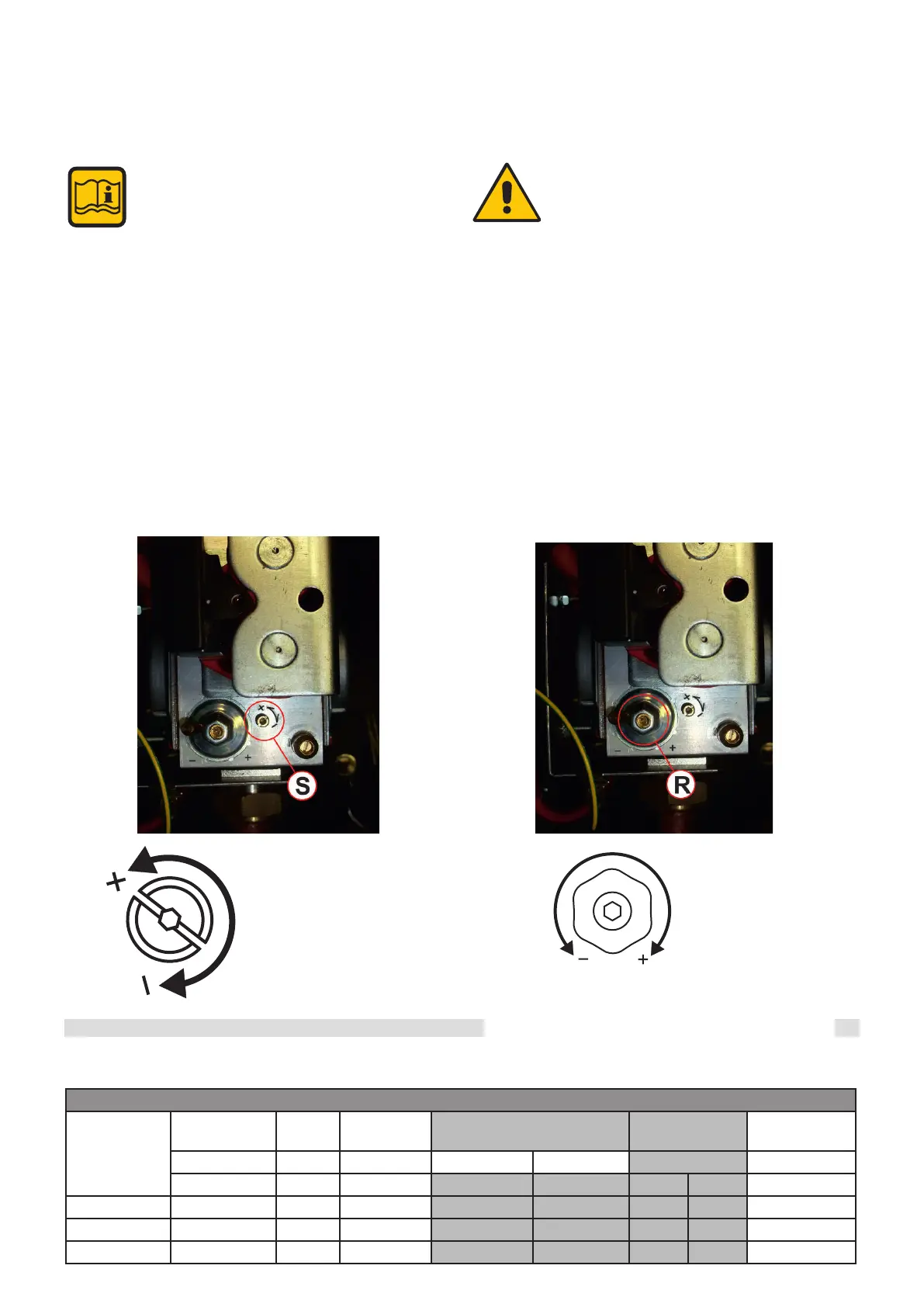

(R)

MINIMUM POWER

ADJUSTING SCREW

- Remove the cap and insert the CO2 analysis probe into the ue gas

output of the intake/exhaust terminal, see chap. 3.12.2.

All boilers are factory calibrated and tested. If necessary,

recalibrate the gas valves (MODULE1, MODULE 2, etc.)

2) Adjustment at minimum power:

- Start the boiler in “calibration” mode at MINIMUM POWER (see

3.12.1)

- Once the burner is on, check that the CO2 value at “MINIMUM”

power corresponds with what is indicated in the “NOZZLES - PRES-

SURES” table.

- If necessary, correct the value by turning (using a 2.5 mm Allen

key) screw “R”; CLOCKWISE increases it and ANTICLOCKWISE

decreases it (refer to the “NOZZLES - PRESSURES” table).

1) Adjustment at maximum power:

- Start the boiler in “calibration” mode at MAXIMUM POWER (see

3.12.1)

- Once the burner is on, check that the CO2 value at “MAXIMUM”

power corresponds with what is indicated in the “NOZZLES - PRES-

SURES” table.

- If necessary, correct the value by turning adjusting screw “S”

CLOCKWISE to decrease it and ANTICLOCKWISE to increase it

(see the NOZZLES-FLOW RATES-PRESSURES table).

Instructions for the installer

ARES TEC ErP: 440-550-660-770-900

Type of

Gas

Supply pressure Ø Noz-

zles

Diaphragm Fan speed CO

2

levels Power at ignition

[mbar] (mm) [mm] Min

.

Max

.

[%] [%]

FL Min

.

FU Max

.

Min

.

Max

.

IG

Nat. gas (G20) 20

9

-

28 108 8.8

8.8

50

Nat. gas (G25) 25 9 -

28 113 9.1 8.5

50

Propane (G31) 37

9

-

28 101 10.8 10.6 50

NOZZLES - PRESSURES - FLOW RATES TABLE

+/- 0.2%

Loading...

Loading...