5 / 44

NL

EN

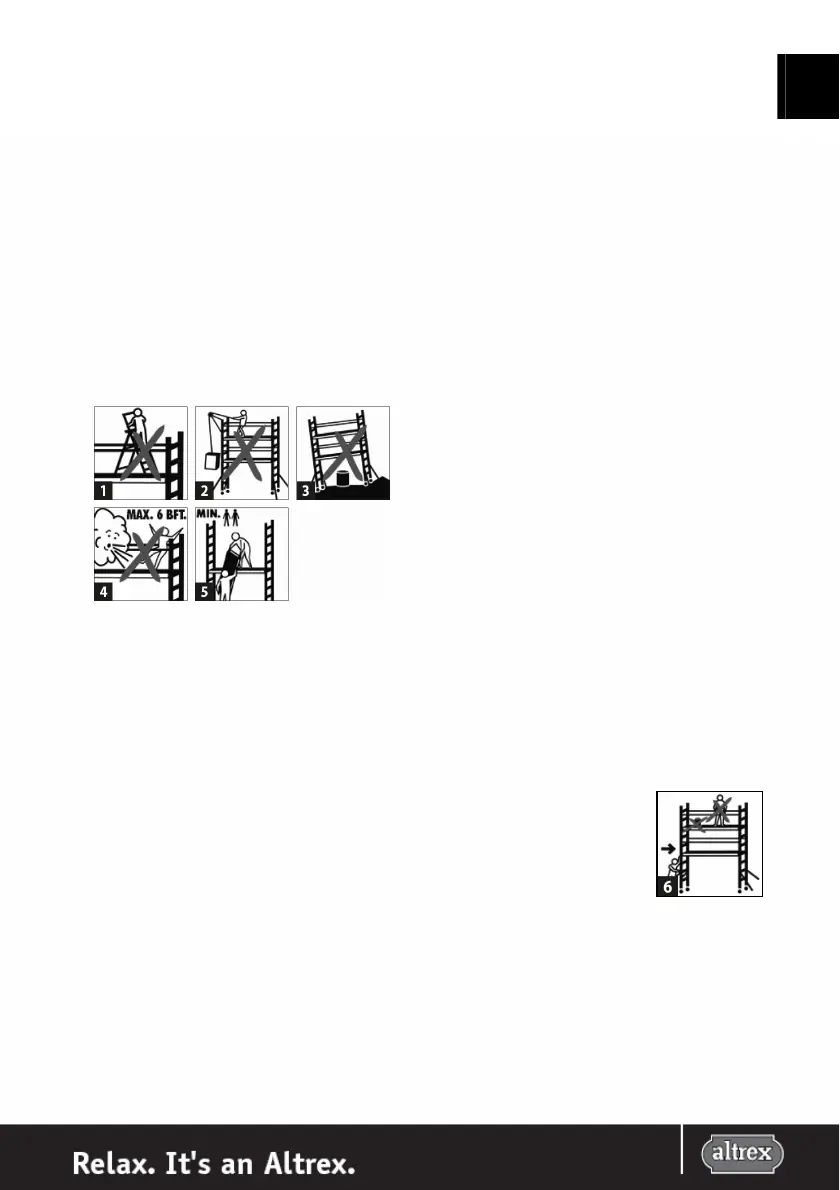

Take sufficient measures against environmental factors

that will help to ensure safe working on the tower.

Use guardrails when this is required from a safety or

legislative point of view.

Never leave the tower unsupervised. Make sure that

unauthorised individuals cannot gain access to the tower.

The mixing of scaffolding parts of different brands /

manufacturers is not permitted, as this endangers safety

because no strength and stability calculation has been

made for that mix configuration.

The workplace around the tower has to be cordoned off

using cones and/or marking tape.

If required, attach the stabilizers. Use the correct stabilizers

with the corresponding platform height. It is not

obligatory when less than 2.5m but it is recommended

for work which involves significant horizontal forces.

Make sure that safe working with the tower is always

given priority.

A minimum of 2 people should always be used to

assemble a tower, see figure 5.

II.III

Checklist for the use of towers

When an assembled tower is (re)used, the following should

always be checked:

1.

that the tower is the correct one for the intended use;

2.

that the immediate vicinity in which the tower is

assembled allows for safe use;

3.

that the tower can still be used safely;

4.

that the quality of the surface is horizontal, flat and

sufficiently load bearing;

5.

that the environmental factors, such as opening doors,

automatically working sun blinds, aboveground electrical

cables, traffic and/or passers-by, etc., do not lead to

dangerous situations;

6.

that there is sufficient free space to be able to assemble

and use the tower safely;

7.

that all required parts and safety tools are available at the

workplace;

8.

that no damaged parts or parts other than those

prescribed are used;

9.

that the tower is assembled in accordance with this

manual and in conformity with the configuration and

ballast table;

10.

that the maximum assembly height is not exceeded;

11.

that it is easy to climb up the inside of the tower;

12.

that the wheels are properly attached, aligned, and that

the brake is applied;

13.

that the frames are properly assembled and secured;

14.

that the horizontal and diagonal braces are assembled

and secured in the correct position;

15.

that the stabilizers that correspond with the permitted

platform height are assembled correctly;

16.

that the tower is perpendicular(check using a spirit level);

17.

that the tower is stable;

18.

that the platforms are situated in the correct position and

the wind security lock is secured in place;

19.

that there is a rest platform at least every 4 meter;

20.

that the tower configuration is inspected frequently (see

inspection sticker);

21.

that all locking pins are in place in the construction and

that these are locked.

II.IV Inspection, Care and Maintenance

1.

Tower parts must be handled and transported with care,

in order to avoid damage.

2.

Storage should be organised in such a way that only

undamaged parts, in the correct amounts, are available

for assembly of the tower.

3.

Check all moving parts for correct functioning and to

ensure that these are not contaminated.

4.

Check all parts for damage. Damaged or incorrect parts

may not be used.

5.

Damaged parts have to be returned to the manufacturer

for inspection.

6.

Towers for professional use must be inspected annually

for any defects by an expert.

7.

The tower must be inspected again before use and in the

case of an emergency such as a storm etc.

II.V Disassembly of the tower

The tower should be disassembled following the instructions

for assembly but in reverse order.

II.VI Relocating the tower

In order to relocate the tower the height has to be

reduced to a maximum of 6.2 meter.

In order to relocate the tower, the stabilizers have to be

raised to a maximum of 10 cm.

The wheel legs are released by pressing the brake pedal.

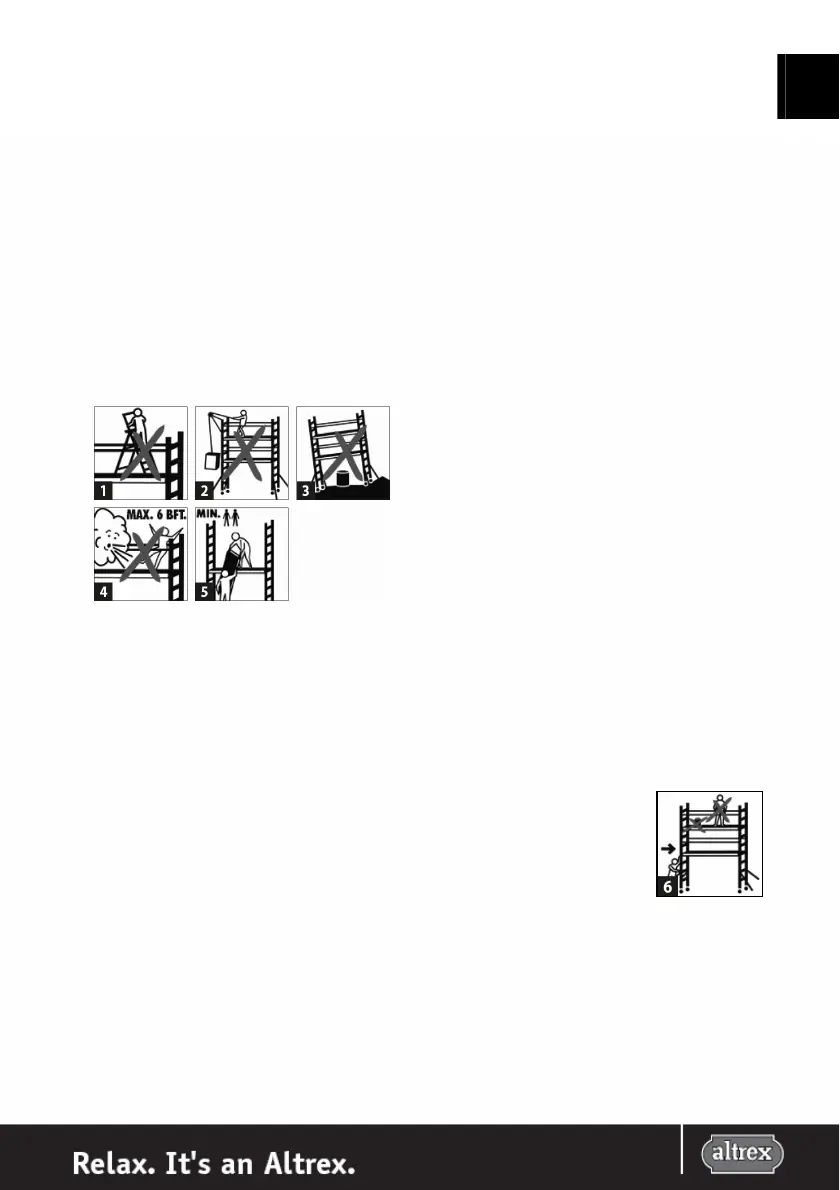

When the tower is being

relocated, persons and/or

materials may not remain on the

tower (figure 6).

Beforehand, checks should be

made that the environmental

factors, such as opening doors,

canopies, pits, automatically functioning sun blinds,

aboveground electrical cables, traffic and/or passers-by,

etc. do not pose the risk of dangerous situations while

the tower is being relocated.

Only relocate a tower in the lengthways direction or in the

diagonal direction, manually, over a flat, horizontal and

sufficiently load-bearing surface. Make sure that the

tower does not start to slant during relocation.

Immediately after relocating the tower, the wheel legs

have to be applied and locked, by pressing the brake

pedal.

GENERAL

Loading...

Loading...