8 / 44

EN

NL

EN 1004-3-8/8-XXXD

III.II Method of assembly rolling tower 4100

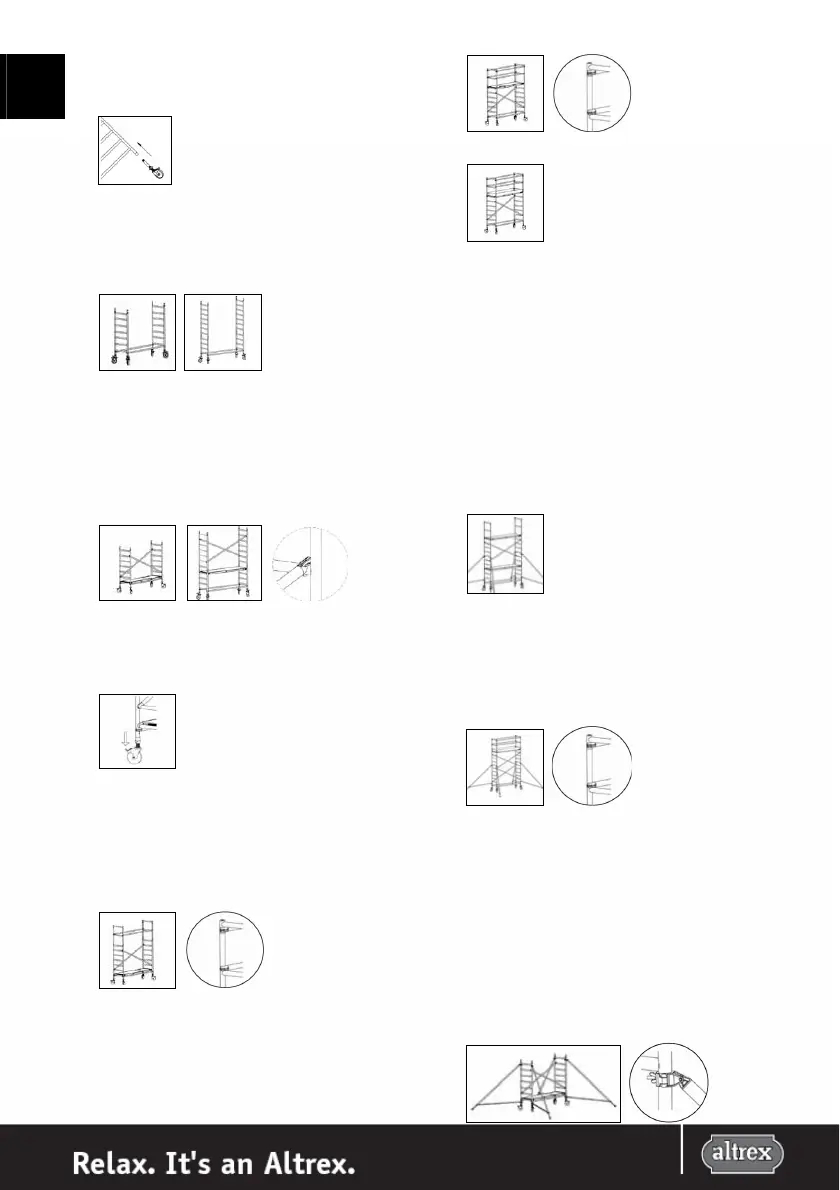

1.

Fit the wheels in the base frames or in the 4 rung frame in

the event of uneven platform heights.

2.

Connect the base frames by using 2 horizontal braces.

Assemble the horizontal braces, working from the inside

to the outside and under the 1

st

rung to the uprights of

the frames. In the event of uneven platform heights:

place two 7 rung assembly frames and secure with the

locking pins supplied.

3.

Then place two diagonal braces in a cross between the 2

nd

and the 6

th

rung of the base frame, one on the left and

one on the right side of the frame. Place a platform with

trapdoor on the first rung of the base frame. In the event

of uneven platform heights, place a platform with

trapdoor on the upper rung of the 4 rung frame. Stand on

the platform and then position two diagonal braces

between the 2

nd

and 6

th

rung of the 7 rung assembly

frame.

Align the wheels so that they point outwards. Lock the

wheels by pushing down the brake pedal. Then set the

base frame horizontally in the length and width direction

using a spirit level on the bottom rung and horizontal

brace.

For a configuration with a platform height of 2.2 meter

follow step 4, 5, and 6.

4.

Stand on the underlying platform and attach 2 guardrail

frames to the base frame of the rolling tower. Secure the

guardrail frames with the locking pins. Then, assemble

the knee braces, working from the inside to the outside,

against the uprights of the guardrail frames.

5.

Subsequently reposition the platform with trapdoor to the

7

th

rung of the (base) frame. Sit through the platform

trapdoor and assemble the top two guardrail braces

working from the inside to the outside against the

uprights of the guardrail frames.

6.

Attach the toe boards (see II.IX).

The rolling tower is now ready for use for a platform

height of up to 2.2 meter.

For a configuration with a platform height of 3.2 meter

follow step 7, 8, and 9.

7.

From the platform, position the 2 guardrail braces on the

assembly frame. Secure the guardrail braces with the

locking pins. Position a platform with trapdoor on the 7th

rung of the assembly frame. Assemble the 4 stabilizers on

the corners of the tower at an angle of about 120° to the

longitudinal access of the tower. Attach the couplers of

the stabilizers to the uprights under the 2

nd

and 7

th

rungs.

Make sure that the end of each stabilizer is in contact

with the solid surface and secure the stabilizer. Position

the lower arm of the stabilizer approximately horizontal,

secure the coupling and check the 120° angle.

8.

Sit through the platform trapdoor and assemble the

guardrail braces working from the inside to the outside

against the uprights of the guardrail braces. Attach the

toe boards(see II.IX).

9.

The lower platform must be removed before the tower

can be used. Then place 2 diagonal braces in a cross

between the 2

nd

and 6

th

rung.

The tower is now ready for use.

Further assembly of 7 rung frames to a platform height of

4.2 meter.

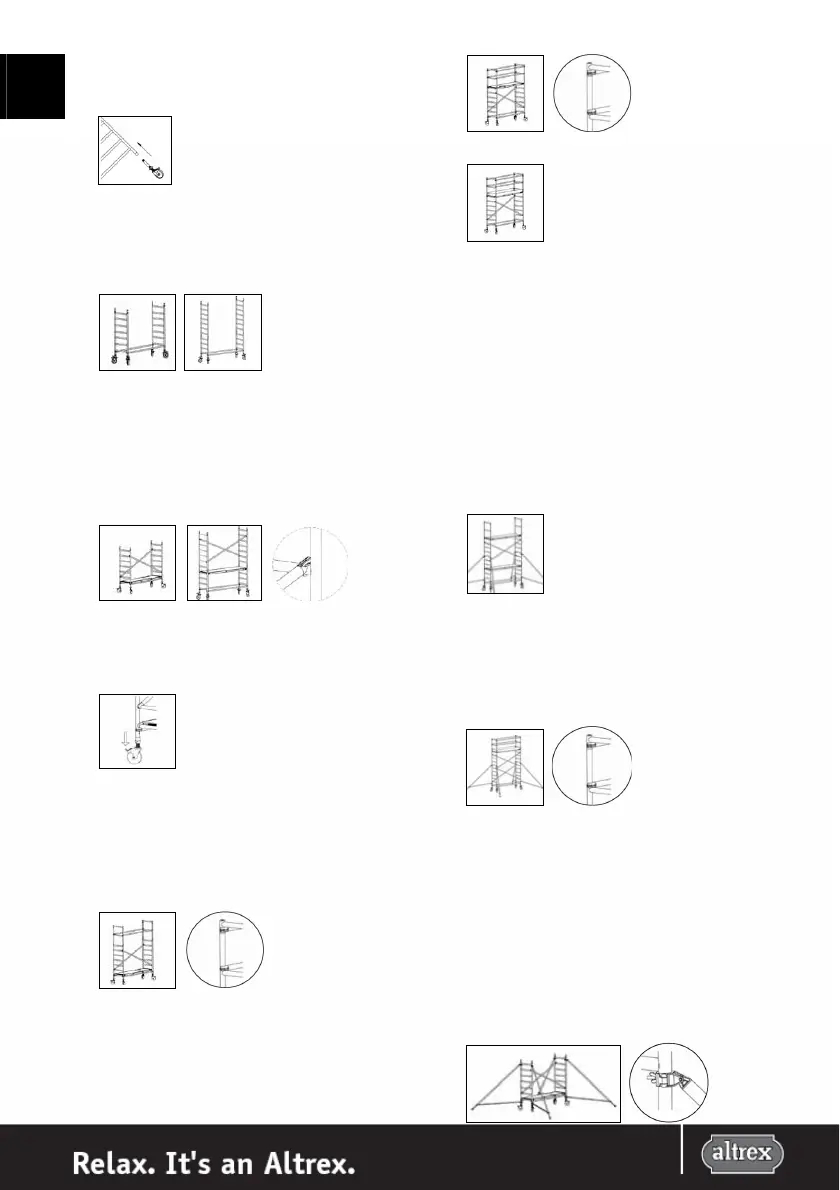

10.

Assume the base frame described in step 3. Attach the 4

stabilizers to the corners of the tower, at an angle of

approximately 120° to the longitudinal axis of the tower.

Attach the couplers of the stabilizers to the uprights

under the 2

nd

and the 7

th

rung of the frames. Make sure

that the end of each stabilizer is in contact with the solid

surface and secure the stabilizer. Position the lowermost

arm of the stabilizer approximately horizontally,

assemble the stabilizers securely and check the angle of

120°.

Loading...

Loading...