4

5.6 Access

This unit should be installed in a manner so that it is not

accessible to the public.

6 Installation Location

NOTE: These air handlers are designed for indoor installation

only at a max altitude of 10,500 feet above sea level or a min

altitude of -184 feet below sea level.

If the unit is located in an unconditioned area with high

ambient temperature and/or high humidity, the air handler

may be subject to nuisance sweating of the casing. On

vapor barrier is recommended. A secondary drain pan below

the unit is also recommended to protect the installation site.

shown in Figures 2, 3, 4 and 5. The unit may be installed

sections for more information).

6.1 Upow and Downow Installation (Figure 2 & 3)

1. Remove blower access panel and coil access panel.

The coil access panel and tubing panel may remain

screwed together during this procedure. Remove and

retain the seven (7) screws securing the coil access

panel to the cabinet and the six (6) screws securing the

blower access panel to the cabinet.

2. Slide the coil assembly out from the cabinet. Use the

drain pan to pull the assembly from the cabinet.

IMPORTANT: Do not use manifolds, copper lines, or

so may result in braze joint damage and leaks.

3. Removal of the center support is required on units

with 21” wide cabinet. Remove and retain the two (2)

screws that secure the center support to the cabinet.

Remove the center support.

a. Using the drain pan to hold the coil assembly, slide

the coil assembly back into the cabinet.

b. Reinstall the center support (if removed) using the

two (2) screws removed in Step 3.

c. Reinstall the coil access panels and reinstall

blower access panel removed in Step 1 as shown

in Figure 8.

a.

b. Using the drain pan to hold the coil assembly, slide

the coil assembly back into the cabinet on the

c. Reinstall the center support (if removed) using the

two (2) screws removed in Step 3.

d. Reinstall the coil access panels and reinstall

blower access panel removed in Step 1 as shown

in Figure 9.

Side Drain Pan and Extension Removal Instructions

Refer to Figure 1, remove the two (2) screws that secure

the drip shield support brackets to the condensate collectors

(front and back). Unsnap the side drain pan from the bottom

drain pan using a screwdriver or any small lever. The side

drain pan, drip shield brackets and the drain pan extension

may now be removed. From Figure 1, drain port labeled (A)

is the primary drain for this application and condensate drain

line must be attached to this drain port. Drain port (a) is for

the secondary drain line (if used). When the side drain pan is

removed, the drain port opening in the access panel must be

covered by the accessory drain port plug (DPK1) as shown

in Figure 1.1.

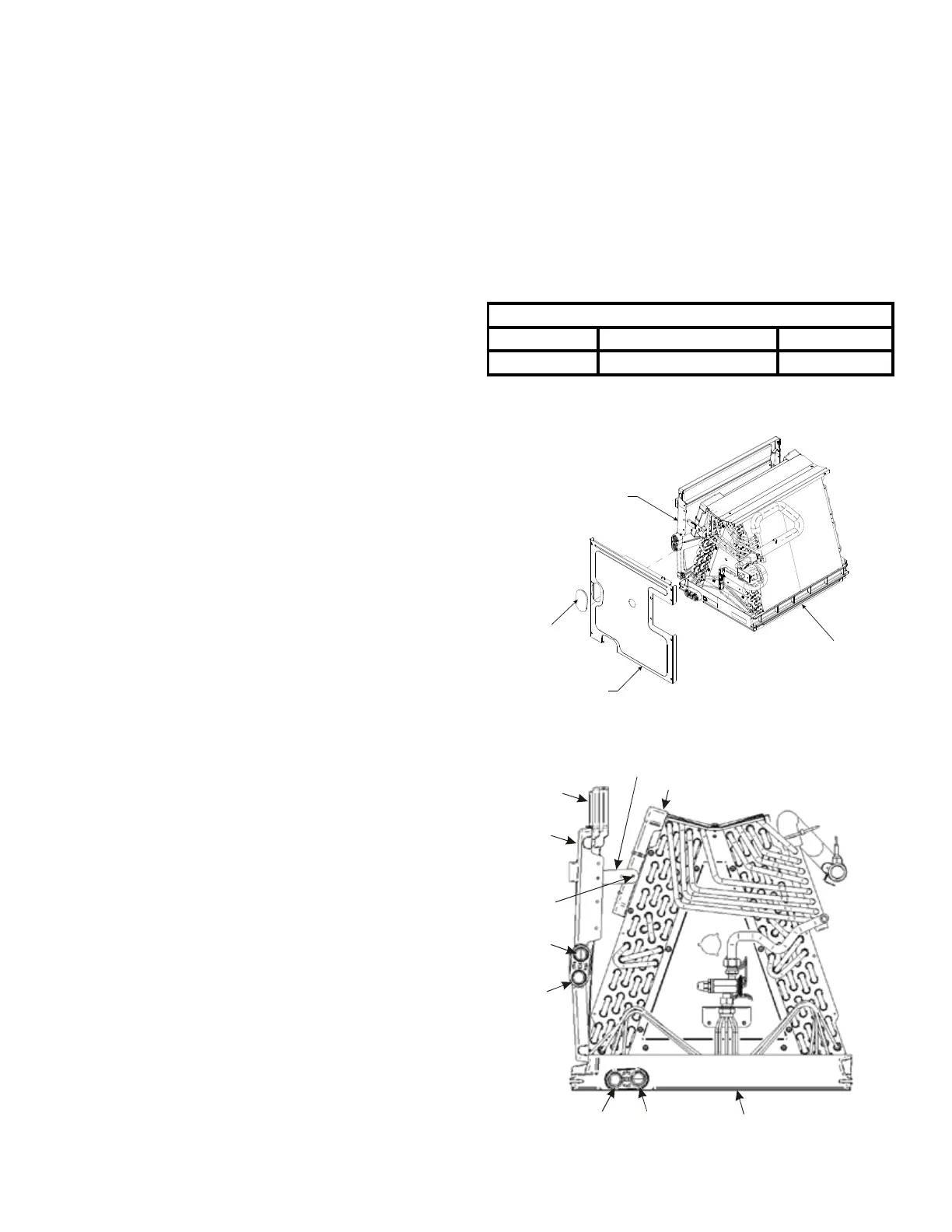

DPK1 All Models

DRAIN PORT PLUG KIT

Table 1

SIDE DRAIN PAN

DPK1 DRAIN PLUG

COIL ACCESS PANEL

DRAIN PAN

Figure 1.1

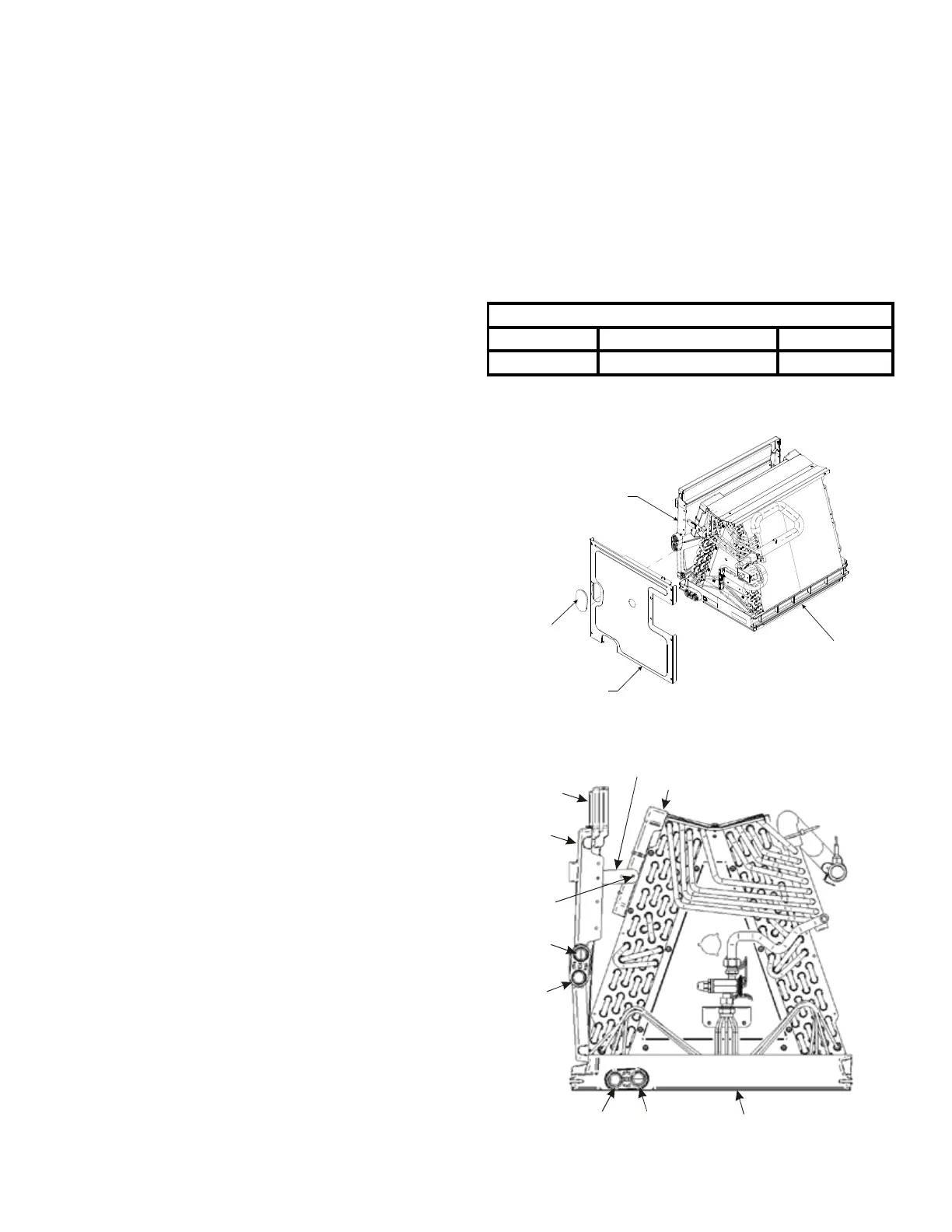

rip Pan

xtension

Side

Drain

Pan

Screw

B

b

A

Main Drain Pan

Drip Shield Bracket

Drip Shield

Pna

SIDE DRAIN PAN REMOVAL

Figure 1

Loading...

Loading...