8

7.4 Tubing Connections for Flowrator Model

1. Loosen the 13/16 nut 1 TURN ONLY to allow high

pressure tracer gas to escape. No gas indicates a

possible leak.

2. After the gas has been expelled, remove the nut and

discard the black or brass cap plastic seal.

3.

for the outdoor unit being installed and then replace the

piston (changing size, if needed). See piston kit chart in

the literature kit for appropriate piston size.

4. Remove the spin closure on the suction line using a

tube cutter and deburr the tube.

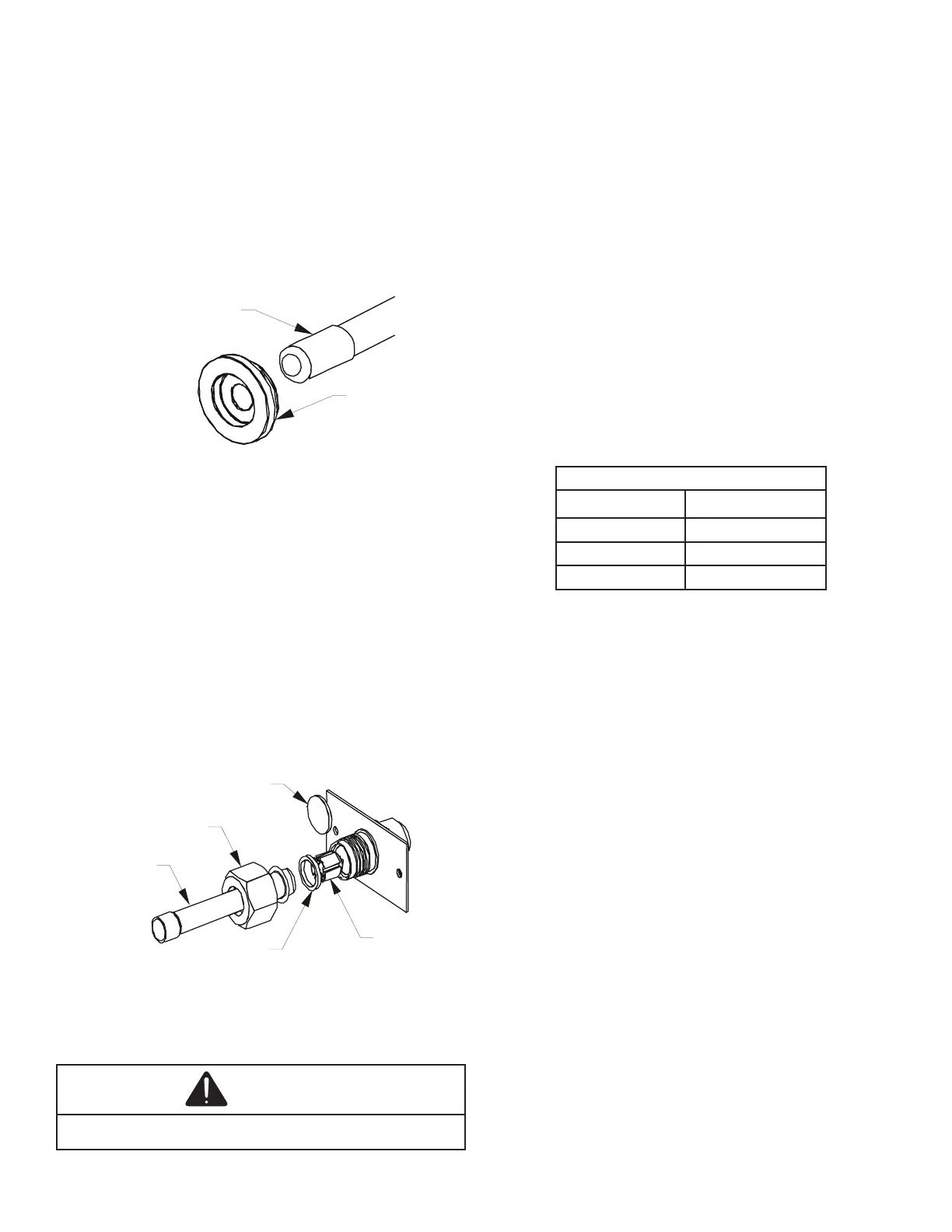

RUBBER

GROMMET

SUCTION LINE

WITH SPIN CLOSURE

SUCTION SPUN END AND GROMMET

Figure 10

5. Insert the suction line into the connection, slide the

insulation and the rubber grommet at least 18” away

from the braze joint.

6. Remove the tailpiece clamped to the exterior of the

cabinet or in the literature kit packet and slide the

7. Braze tailpiece to the line set liquid tube and braze

suction line connection. Quench all brazed joints with

a damp rag upon completion of brazing. Do not allow

water to enter the inside of the tubing.

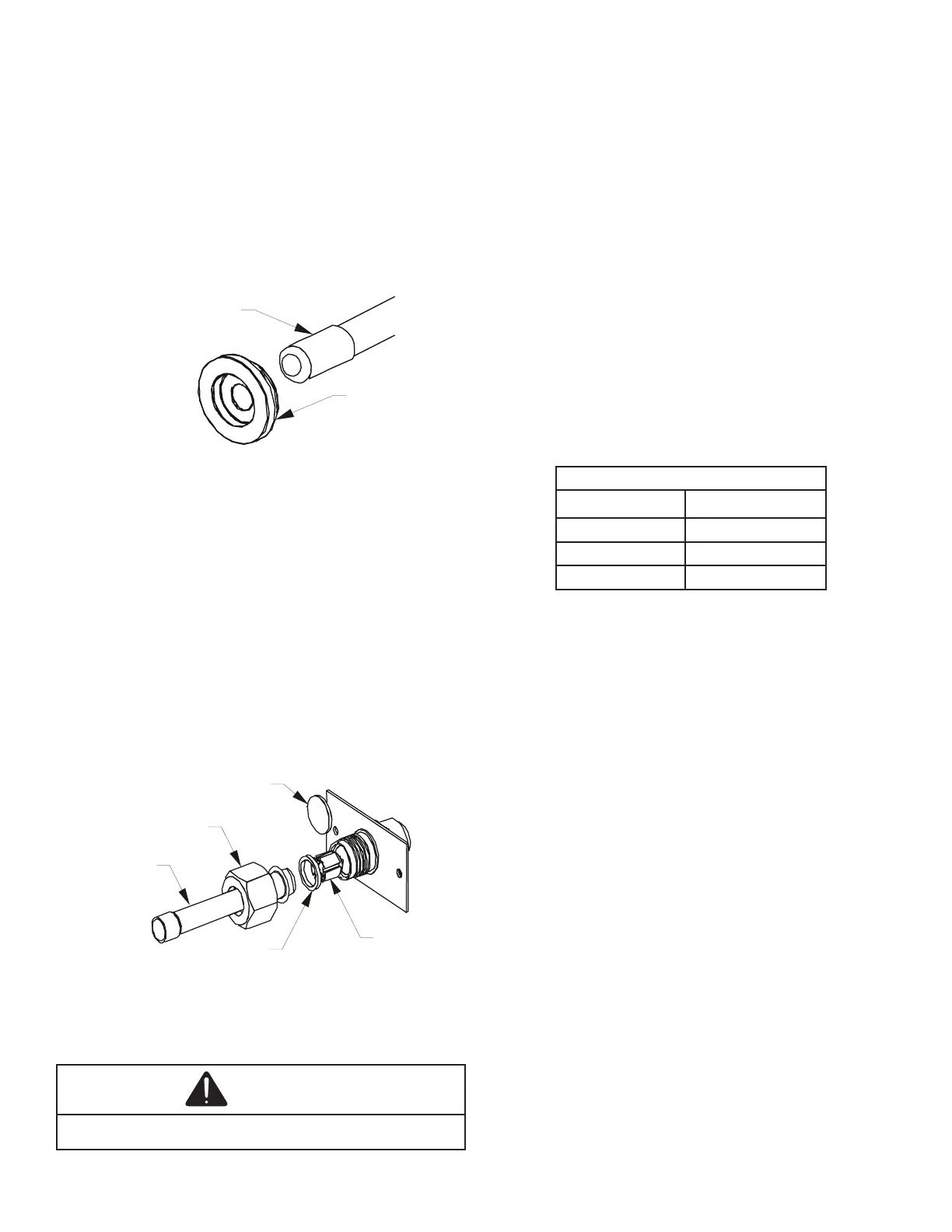

AFTER THE TAILPIECE HAS COOLED

13/16 nut.

WHITE

TEFLON SEAL

PISTON

TAILPIECE

13/16” NUT

PLASTIC or BRASS CAP

TAILPIECE JOINT

Figure 11

9. Torque the 13/16 nut to 7-25 ft-lbs. or tighten 1/6 turn.

CAUTION

7.5 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the

bulb pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access

panel.

2.

indicates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction

tubes using a tubing cutter.

5. Insert liquid line set into liquid tube expansion and slide

grommet about 18” away from braze joint.

6. Insert suction line set into suction tube expansion and

slide insulation and grommet about 18” away from

braze joint.

7. Braze joints. Quench all brazed joints with water or a

wet rag upon completion of brazing.

7.6 ASPT**14** Models with Non-Adjustable TXV

ASPT air handlers equipped with Parker non-adjustable

TXV should be charged by subcooling only.

Models

ASPT25B14**A SPT47D14**

ASPT29B14**A SPT47C14**

ASPT37B14**A SPT49D14**

ASPT37C14**A SPT59C14**

Table 4

See section 7.7 for detailed information on adjusting the

thermal expansion valve.

7.7 Thermal Expansion Valve System Adjustment

Run the system at Cooling for 10 minutes until refrigerant

pressures stabilize. Use the following guidelines and methods

to check unit operation and ensure that the refrigerant charge

is within limits. Charge the unit on low stage.

1. Purge gauge lines. Connect service gauge manifold to

base-valve service ports.

2. Temporarily install a thermometer on the liquid line at the

liquid line service valve and 4-6” from the compressor on

the suction line. Ensure the thermometer makes adequate

contact and is insulated for best possible readings. Use

liquid line temperature to determine subcooling and vapor

temperature to determine superheat.

3. Check subcooling and superheat. Systems with TXV

application should have a subcooling of 7 to 9ºF and

superheat of 7 to 9 ºF.

a. If subcooling and superheat are low, adjust TXV to

7 to 9 ºF superheat, then check subcooling.

NOTE: To adjust superheat, turn the valve stem

clockwise to increase and counter clockwise to

decrease.

b. If subcooling is low and superheat is high, add

charge to raise subcooling to 7 to 9ºF then check

superheat.

c. If subcooling and superheat are high, adjust TXV

valve to 7 to 9 ºF superheat, then check subcooling.

Loading...

Loading...