2-2 5000 Multi Point Moisture Analyzer

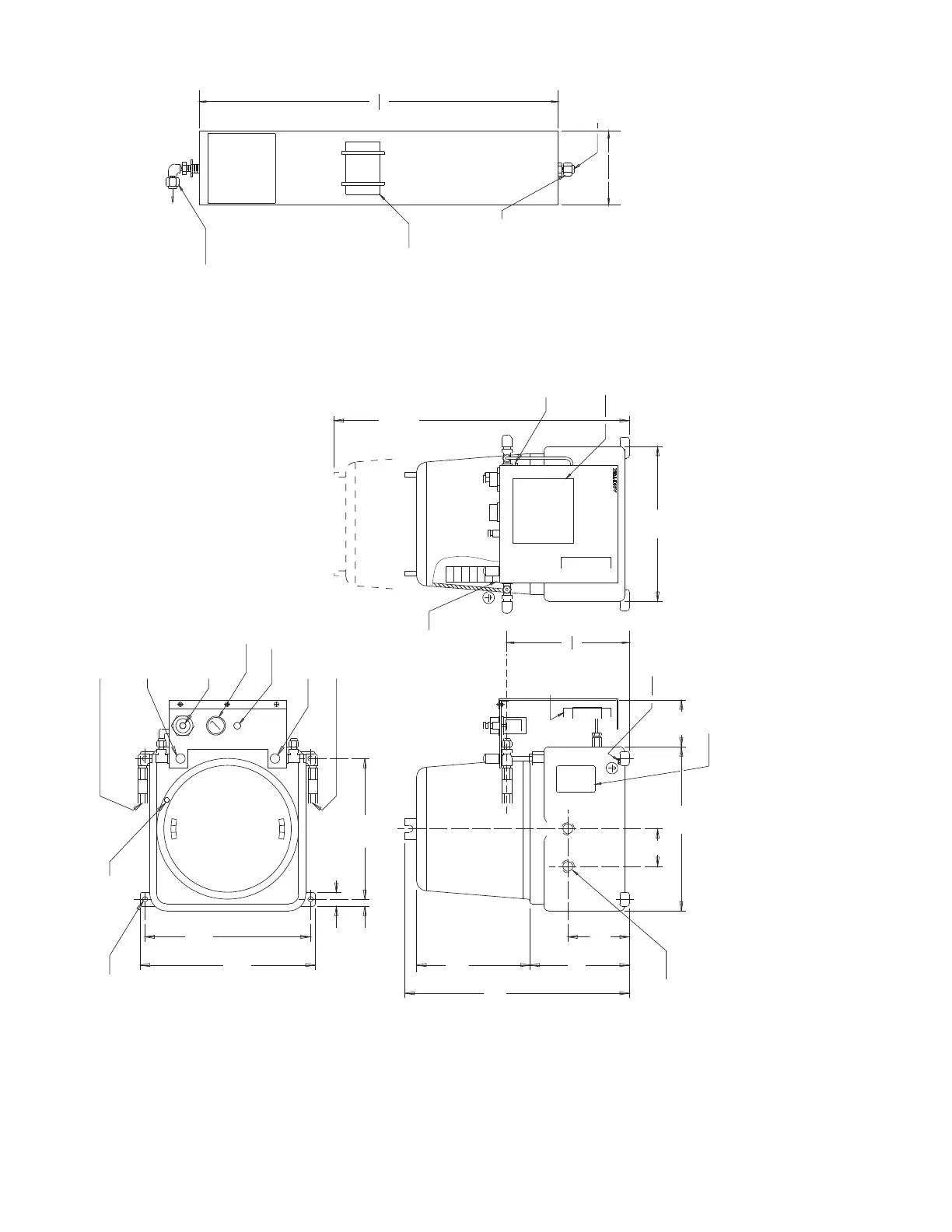

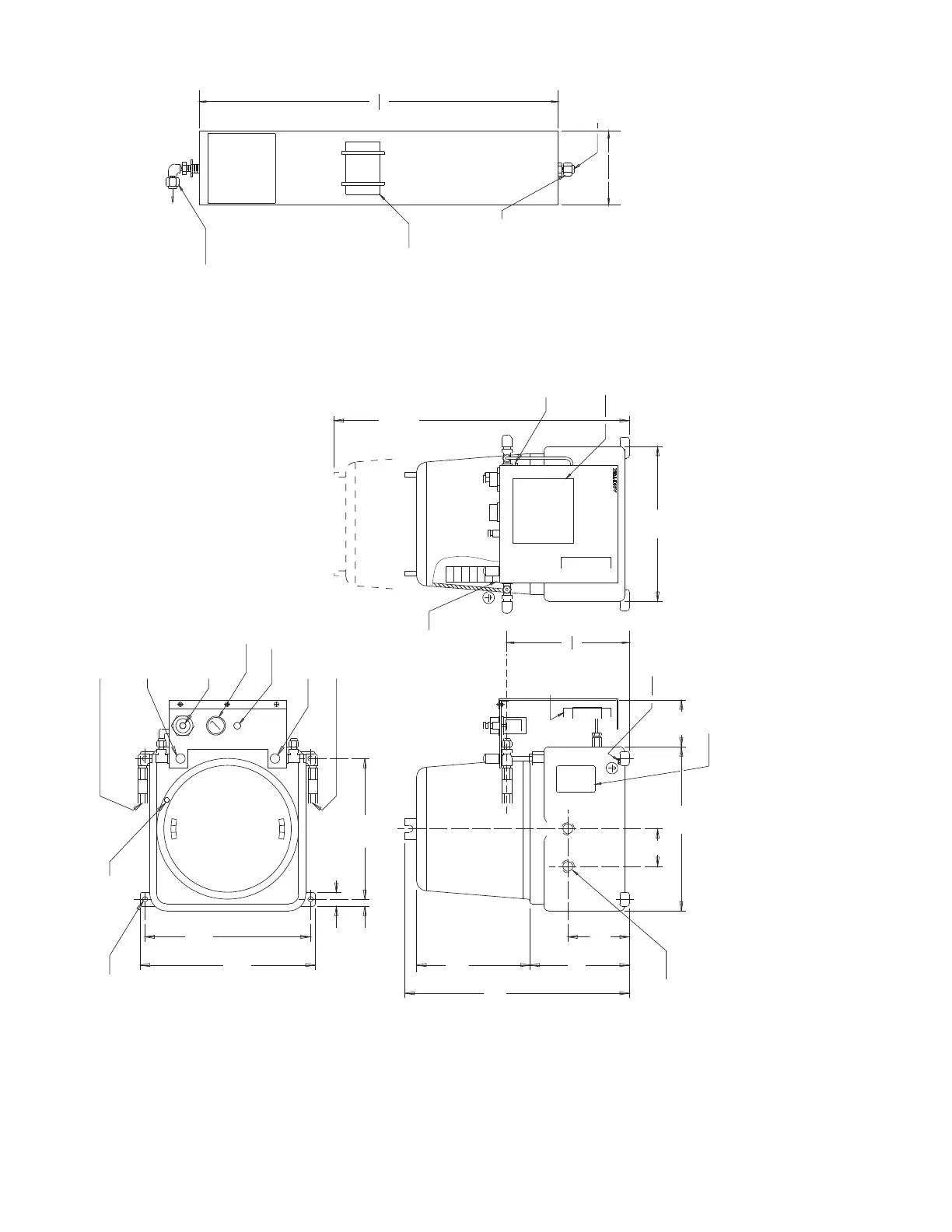

Figure 4: Installation / Dimensional Layout for 5000 Field Unit

GROUNDING LUG

3/4-14 NPT, 2 HOLES

SEE NOTE 2

GROUND CONNECTION

LOCATED BEHIND TB1

GENERATOR FLOW ADJUSTMENT

BACK PRESSURE GAUGE

FLOWMETER

CENELEC CERTIFICATION LABEL

WARNING

MAXIMUM PRESSURE

100 PSIG

DRYER

THIS END UP

DRY GAS OUT

(TO ANALYZER)

1/8" TB FITTING

SEE NOTES 2 & 5

WET GAS

1/8" TUBE FITTING

SEE NOTES 2 & 5

(12.9)

328

(3.25)

83

(17.0)

432

(7.68)

195

(4.75)

121

(8.5)

216

(4 PLACES)

(4 PLACES)

(0.78)

20

(1.56)

40

(10.75)

273

(14.50)

368

(12.81)

325

LOCKING SCREW

4 HOLES

11 (0.44) DIA

5 MM HEX

89

(3.5)

NOTES:

1. XXX DIMENSIONS ARE IN MILLIMETERS, (XXX) DIMENSION ARE IN INCHES

2. FERRULES AND NUTS ARE PACKED IN PLASTIC BAG AND ADHERED TO DRYER

3. CUSTOMER TO MOUNT DRYER CHAMBER TO 5000 ANALYZER FIELD UNIT

TO MINIMIZE TUBE LENGTHS.

4. POSITION VERTICALLY WITH END UP AS NOTED ON BODY.

5. REMOVE DRYER SEAL PLUGS AND INSTALL SUPPLIED NUTS AND FERRULES JUST PRIOR

TO INSTALLATION. MINIMZE INTERNAL CONTACT WITH AMBIENT MOISTURE. PROLONGED

EXPOSURE TO MOIST AIR MAY REDUCE DRYER LIFE.

6. THE SAME DRYER DIMENSIONS CAN BE USED FOR CONTAMINANT TRAP AND

SUPERACTIVATED MOLECULAR SIEVE DRYER.

7. FIELD UNIT EQUIPPED WITH CENELEC REQUIREMENTS PER EN50018.

LESS THAN 69 KPa (10 PSIG)

VENT TO APPROPRIATE AREA

EXHAUST TO VENT

1/4" MALE TUBE FITTING

(11.9)

302

CLEARANCE

MINIMUM

(28.0)

711

REFERENCE ADJUSTMENT

BACK PRESSURE ADJUSTMENT

SAMPLE ADJUSTMENT

1/8" NPT FEMALE

SAMPLE INLET

1/8" NPT FEMALE

REFERENCE INLET

(FROM CONDITIONED REFERENCE

SOURCE)

WARNING LABEL

TB1

WARNING

457

(18.0)

236

(9.3)

89 DIA.

(3.5)

Loading...

Loading...