Do you have a question about the Ametek Dunkermotoren BG 75x50 and is the answer not in the manual?

Introduces the manual and its purpose for the BG 75 EC motor with EtherCAT.

Details the features and advantages of the BG 75 EC motor series.

Defines key terms and concepts used throughout the document.

Explains EtherCAT specific communication mechanisms like CoE, SDO, and PDO.

Outlines the intended application and correct usage procedures for the motor.

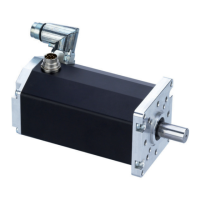

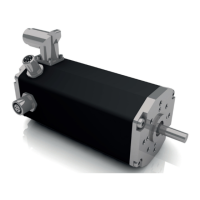

Specifies motor dimensions, connectors, and environmental protection ratings.

Lists electrical parameters including voltage, current, speed, and protection limits.

Presents specific technical data for the BG 75x25 EC motor model.

Presents specific technical data for the BG 75x50 EC motor model.

Presents specific technical data for the BG 75x75 EC motor model.

Provides a visual guide with dimensions for motor installation.

Describes the various control and motion modes supported via EtherCAT.

Explains Dunkermotoren's specific quick start control modes for easy setup.

Details operating modes compliant with the CiA DS402 standard.

Covers integration and operation with the TwinCAT system for NC axis control.

Explains the function of File Access over EtherCAT for firmware updates.

Lists EtherCAT features or functions that are not implemented or supported.

Information regarding product certifications and compliance standards.

Describes the starter kit for easy integration and testing of EtherCAT functionality.

Explains the ESI file as a description of the EtherCAT slave device.

References practical examples for system setup and commissioning.

Lists available user manuals and knowledge base resources.

Details available optional hardware attachments like gears and brakes.

Explains handling of energy fed back during braking and voltage protection.

Describes the built-in thermal protection that switches off the controller.

Details how to set parameters to limit continuous current for protection.

Explains the function of a ballast circuit for managing braking energy.

Provides instructions for physically mounting the motor securely to a surface.

Guides on properly adjusting the angle of the power supply connector.

Covers all aspects of connecting the motor electrically.

Discusses measures to ensure EMC compliance during electrical installation.

Explains the importance and procedure for grounding the motor housing.

Identifies the 4-pin connector for motor power supply.

Describes compatible connectors and cables for the motor power supply.

Details the 12-pin connector for electronics and signal interface power.

Describes compatible connectors and cables for electronics and signal interface.

Advises on maximum cable lengths and power supply considerations.

Shows the pin configuration for the EtherCAT M12 connector.

Identifies the service interface connector and its protection.

Provides a schematic for the power supply circuit, including inrush current management.

Outlines preparatory steps for powering up and connecting the motor.

Explains the meaning of status LEDs for diagnosing communication and operational states.

Describes the general process of configuring an EtherCAT network with a master tool.

Illustrates drive commissioning using Beckhoff TwinCAT as an example.

Covers routine maintenance, safe removal, and environmentally sound disposal procedures.

Lists contact information for technical support and service inquiries.

Refers to the standard delivery contents and optional accessories.

Provides instructions for downloading the manual and related data.

| Stall Torque | 2.6 Nm |

|---|---|

| Stall Current | 14 A |

| Weight | 0.9 kg |

| Max. efficiency | 85% |

| Rated Voltage | 24 V |

| Motor Type | Brushless DC |

| Nominal voltage | 24 V |

Loading...

Loading...