17

Manufactured by: Ronstan Denmark ApS. - Jægervænget 36 - 7100 Vejle – Denmark - info@andersenwinches - www.andersenwinches.com

General Service Instructions

PERIODIC LUBRICATION OF THE MOTOR OUTPUT SHAFT SEAL

In order to avoid potential sea water intrusion and to increase the lifetime of your Andersen electric

winch motor drive, we recommend re-lubrication of the output gear shaft seal once a year.

Remember: Always shut off power to the winch before commencing any service or maintenance task!

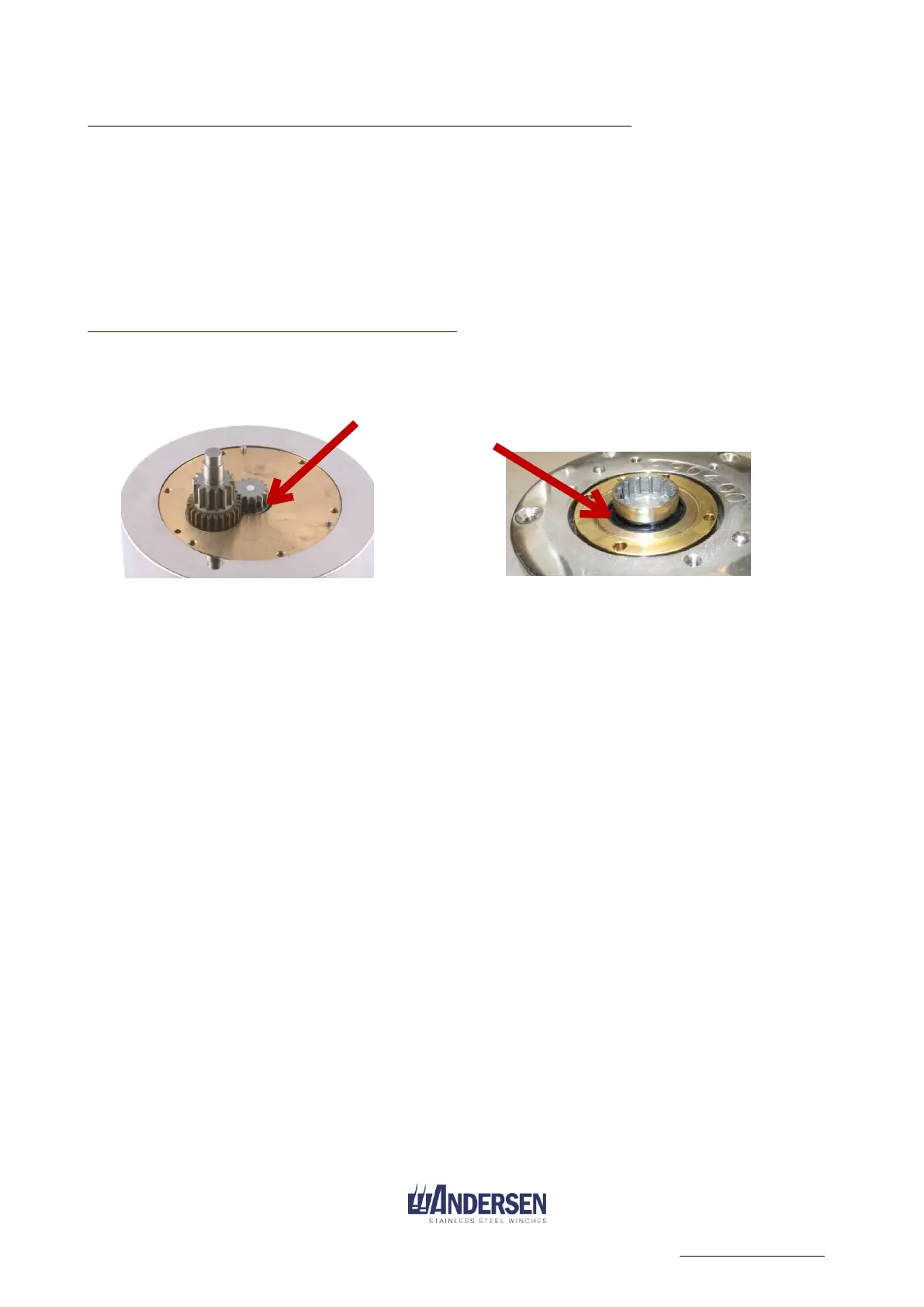

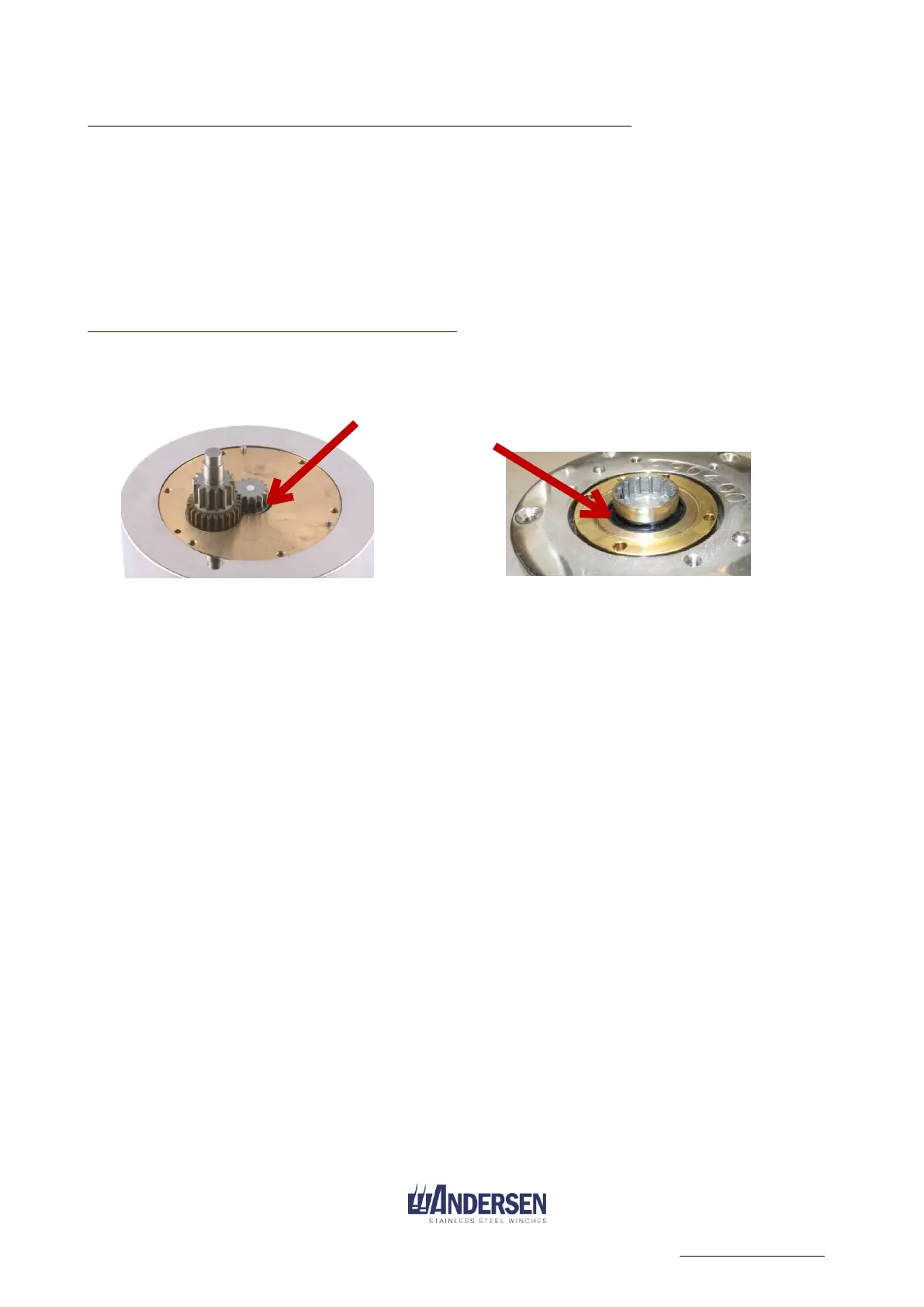

To access the seal for lubrication, it is necessary to remove the winch from the motor for Compact

Electric Above Deck motors (fig.1), or from the stainless steel deck adaptor plate used for motors

fitted below deck (fig.2 and fig.3). On current model winch sizes 46-50-52STE this deck adaptor

plate is an integrated part of the winch base, and you’ll only need to remove the upper winch base

part

as you do for normal winch maintenance.

A high quality bearing grease such as Klüber ISOFLEX TOPAS NB 52 (see details at

http://www.klueber.com/en/product-detail/id/312/) is ideal for lubrication of this seal, although

Andersen Winch Grease is also suitable.

Compact Electric Above Deck Compact Electric Below Deck

Loading...

Loading...