Series SD 39

20

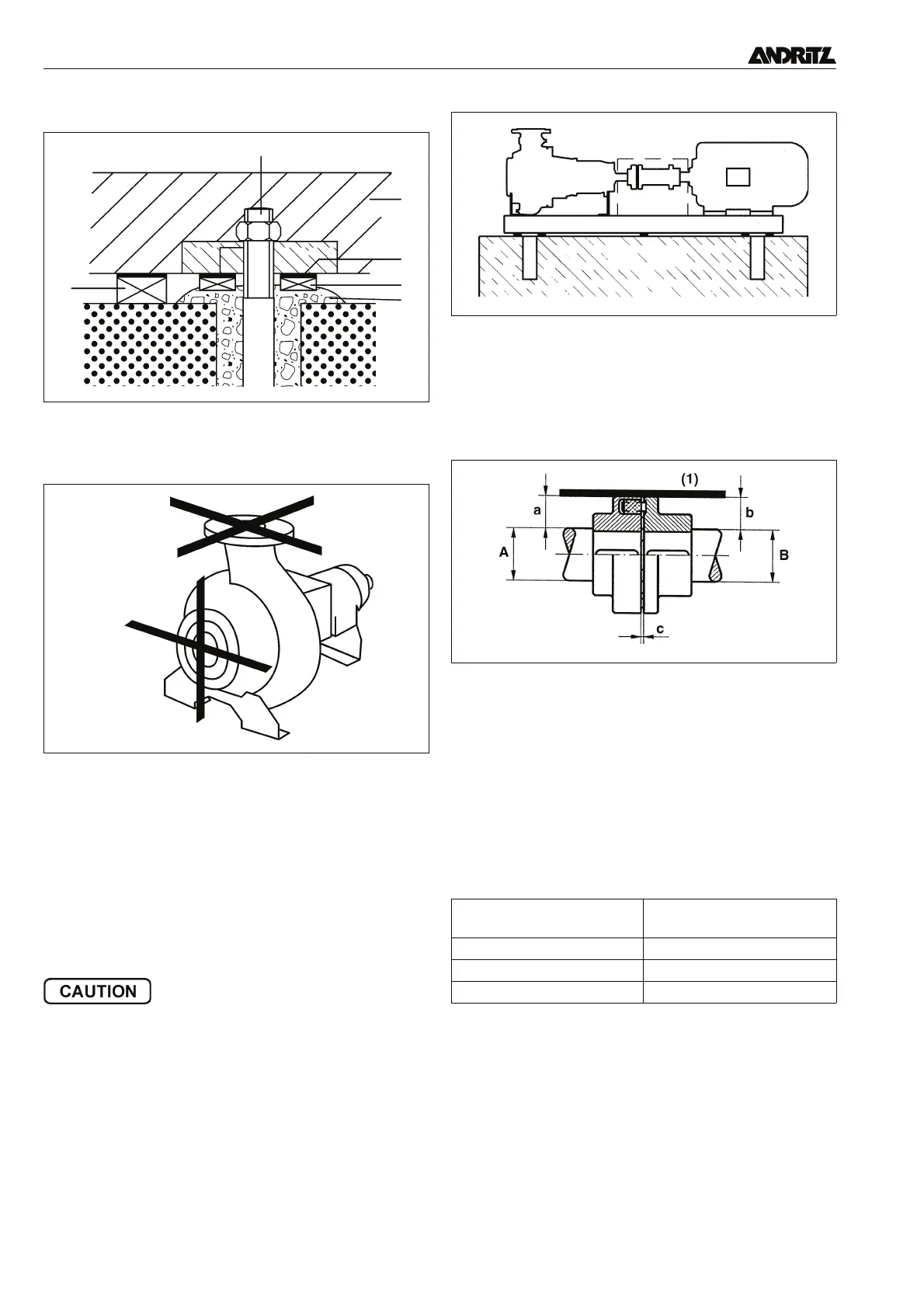

• Place temporary chocks (2) underneath the baseplate (1).

• Check the alignment of pumps on the flange machined sur-

faces using a spirit level. A margin of error of 1 mm in 1 m is

allowed.

• Pour the foundation bolts (3) into place with cement (4) leav-

ing it proud around the bolts (see figure foundation bolts).

• Before the cement sets, insert machined packing pieces (5)

on both sides of each foundation bolt. These pieces should be

attached leaving a minimum distance from the baseplate (1).

• When the cement has set, pack the gap with metal shims of

suitable thickness.

• Remove the temporary chocks (2).

3.3.2 Alignment of flexible couplings (E, H with stub

shaft)

Pump and motor shafts were carefully aligned before delivery.

Displacement can occur during transport thus coupling align

-

ment must be checked before pourring the baseplate.

• Correct vertical misalignment by packing under the base-

plate. For baseplates of up to 1600 mm only place packing in

the drive motor or pump area. Larger baseplates require mul

-

tiple packing.

• Correct lateral misalignment between pump and motor by

slackening the motor fastening bolts, aligning the motor with

the pump and re-tightening.

• Tighten foundation bolts.

After tightening the foundation bolts, the shaft must be free to

be turned by hand without any tight spots (construction with

packed glands: Packed glands must be slackened for this

test!). Alignment errors may cause premature failing of bear

-

ings or couplings and result in noisy running.

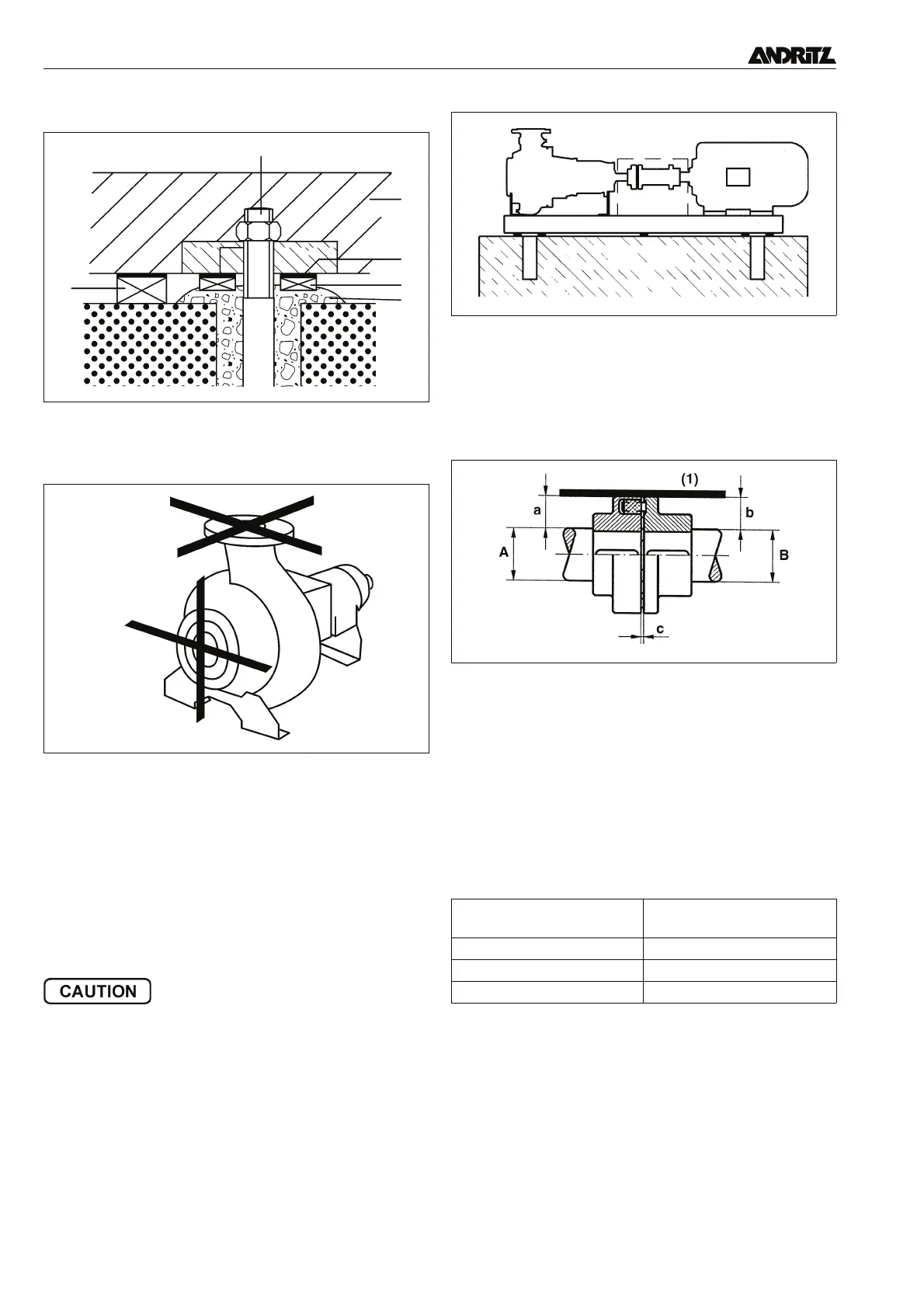

3.3.2.1 Alignment using a straight steel edge

• Place the straight edge (1) axially across the top of the pump

and coupling halves.

• Measure the distances (a) and (b) between the straight edge

and the shafts.

• If the diameter of the pump and motor shaft is equal, then:

a

= b.

• If the diameters differ, then: a + 1/2A = b + 1/2B.

• Repeat the exercise in various positions (displaced by ap-

prox. 90°). The requirements for equal or unequal shaft diam-

eters must be fulfilled in all positions.

• Check the clearance between the coupling halves

(dimension

c). For flexible claw-type couplings this should be:

The distance c must be the same in all positions.

3.3.2.2 Alignment with dial gauges

High rotational speeds and/or spacer type couplings require

more precise alignment using dial gauges.

• Align the coupling halves in both axial and radial directions.

• Maximum permissible axial discrepancy on the coupling face

is 0.05 mm. Preferred value > 0.03 mm. (measure on the out

-

side!).

• Maximum permissible radial discrepancy of coupling periph-

ery is 0.10 mm. Preferred value > 0.05 mm.

Foundation bolts

Pump alignment on the flanges

Correcting vertical alignment

Aligning with a straight steel edge

Coupling Size

(outside diameter)

Distance

c

80-140 mm 2-3 mm

160-225 mm 2-4 mm

250-400 mm 3-6 mm

Table 1: distance between the coupling halves

Loading...

Loading...