Series SD 39

19

ENGLISH

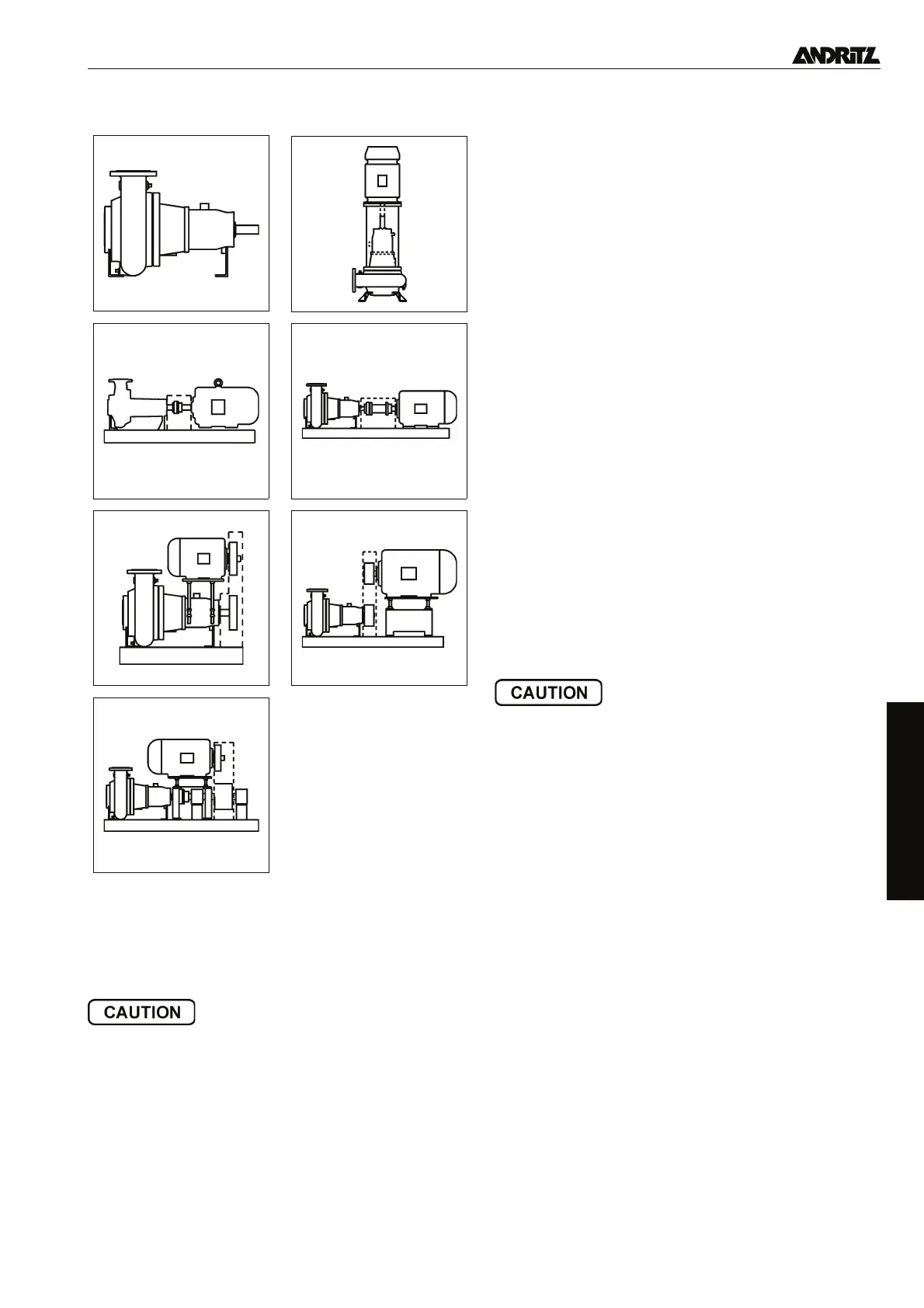

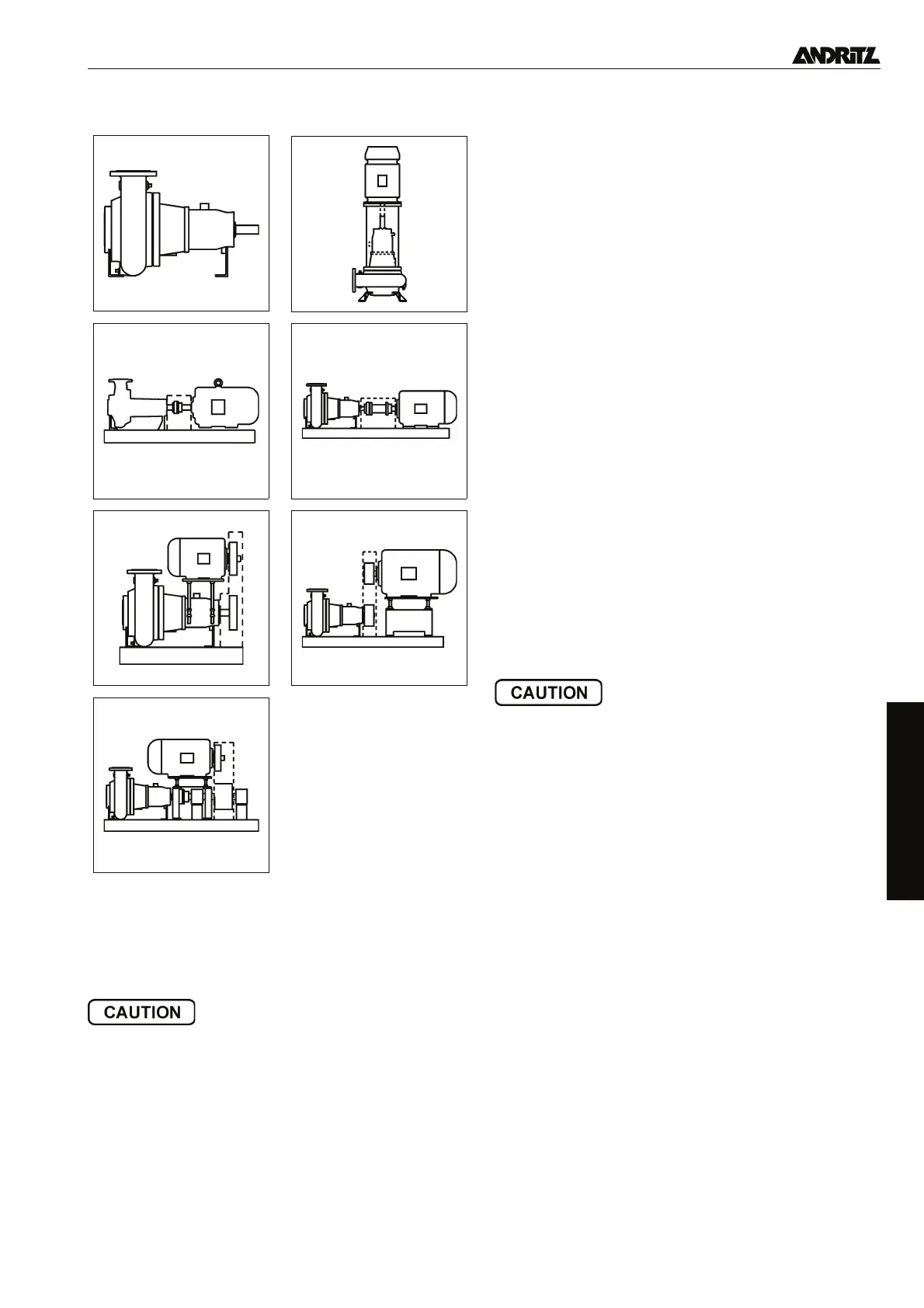

2.2.5 Mounting arrangements

2.3 Dimensions, weights, centres of gravity, capacity

Information on request.

For weights refer to the contract documentation.

2.4 Installation requirements

• Protect motors and pumps from the weather.

• Ensure that the workplace is adequately ventilated/heated/

cooled and observe noise protection requirements.

• Check that access to the pump set (or its components) at the

point of installation is adequate and safe.

Openings must be large enough.

• Adequately rated lifting equipment must be available.

2.4.1 Space required for operation and maintenance

• Ensure that sufficient space is left for subsequent mainte-

nance requirements.

• The set should be easily accessible from all sides.

• The motor cooling fan requires adequate clearance around

the cowl. Ensure that the air inlet and outlet areas are unob

-

structed.

2.4.2 Foundations

• Concrete plinths must be adequately supported in order to

ensure smooth and safe operation.

• Length: At least 100 mm longer than the baseplate.

• Width: The foundation bolts should be at least 100 mm in

front of the edge of the foundation.

• Height: 20-30 mm below final position of underside of base-

plate. If the plinth is to be tiled, make an additional allowance

in order to avoid damaging the tiles should the set have to be

removed.

• The holes in the plinth should be of suitable length for the

foundation bolts used.

• The depth of the foundation should be sufficient to prevent

frost.

• Plinths which rest on a structural floor or ceiling should be in-

tegrated into the original construction using bridging rein-

forcement.

• Foundations should contain sufficient mass in order to damp-

en system vibrations.

• Do not place rubber, cork, feather and/or resilient mats be-

tween baseplate and plinth.

2.4.3 Supply connections

Check that all supplies (power, water etc.) necessary for instal-

lation and later operation are available at the intended pump

position.

3. Mounting/installation

Care and attention to detail during installation are essen-

tial for a trouble-free operation. Incorrect procedures dur-

ing installation may create hazards for personnel or

property or lead to premature failure of the pump.

3.1 Preliminary checks

Check that the dimensions of the plinth/foundation are in ac-

cordance with the drawings.

3.2 Mounting of pump and motor (arrangement A)

See also para. 3.3.

• Common baseplate mounted pump and motor: Adjust the ax-

ial clearance between pump and motor shaft ends.

• Separately mounted pump and motor: Secure the pump onto

the plinth and align it. Then secure the motor and align it with

the pump.

• V-belt drive requires explicit authorisation in our confirmation

of order.

3.3 Installation of assembled pump sets

3.3.1 Horizontal pumps with base plate-mounted drive

motors (E, H, HZ, H with stub shaft)

• Before lowering the set into position clean the plinth surface

and remove any limewash to ensure sound bonding.

• Hang the foundation bolts with nuts in the baseplate fixing

holes.

• Lower the set into position on the plinth surface.

Loading...

Loading...