Apeks Supercritical The Duplex™ Operation Manual

11

Revision Date 8/28/2018

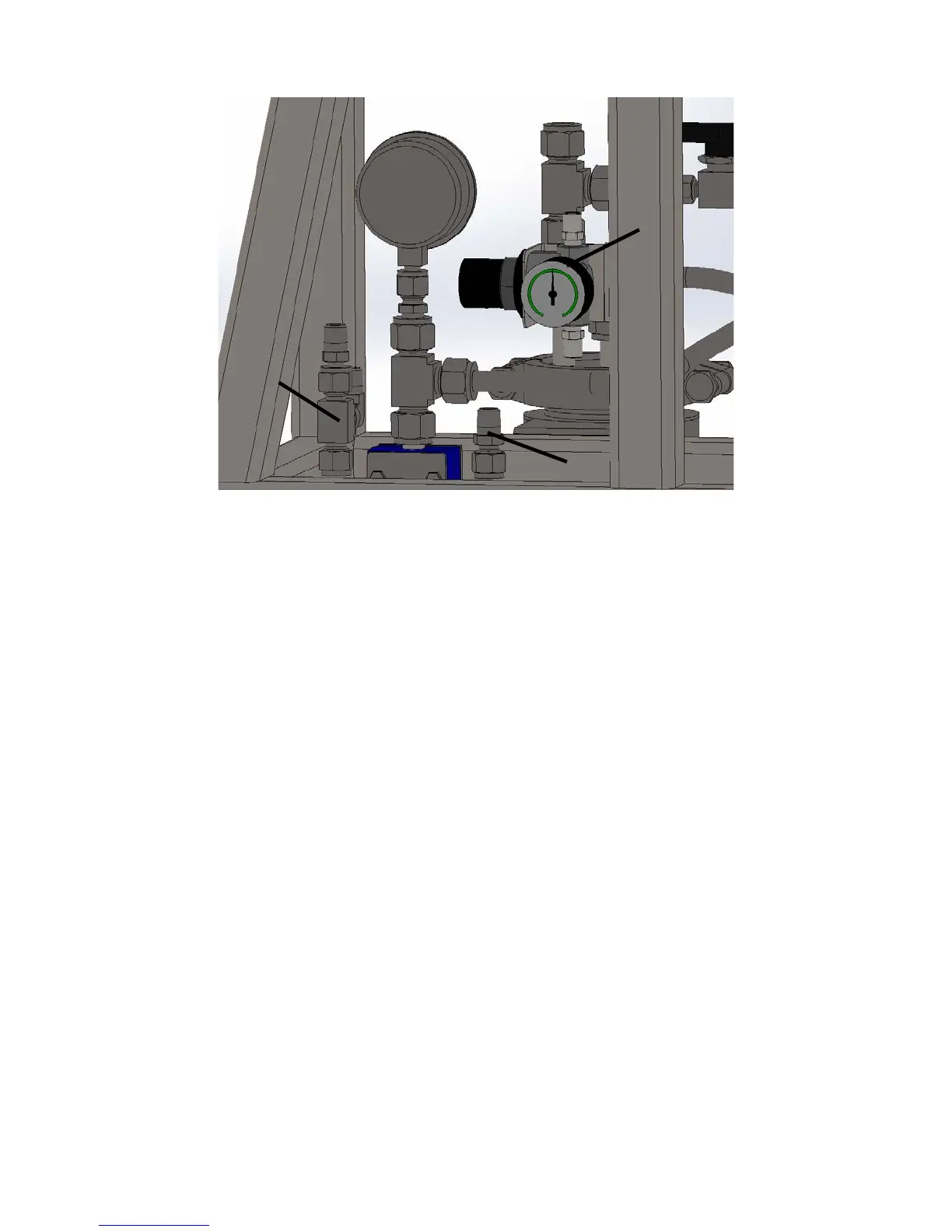

2.1.4. Bottle Connections

2.1.4.1. Main Supply and Recovery Bottles – Three 75lb Gas Supply CO

2

bottles should be

used as the main bottles for The Duplex™ system. These bottles are connected to the

location shown above.

2.1.4.2. CO

2

Make-Up Supply Bottle – One 50 to 75lb Gas Supply CO2 bottle should be used

as a makeup bottle for CO

2

lost during and at the end of each cycle. This bottle is

connected to Valve 20 in the location shown above.

2.1.5. Extractor Chiller/Temperature Control Chiller – The Extractor Chiller is used to control the

temperature of the CO

2

before it passes over the raw material in the extraction vessel. Refer to

Installation Manual for chiller loop setup and chiller manual for more information on the chiller.

2.1.6. Separator Chiller/Regenerative Chiller – The Separator Chiller is used to control

temperatures of your CO

2

after compression or expansion. Refer to Installation Manual for

chiller loop setup and chiller manual for more information on the chiller.

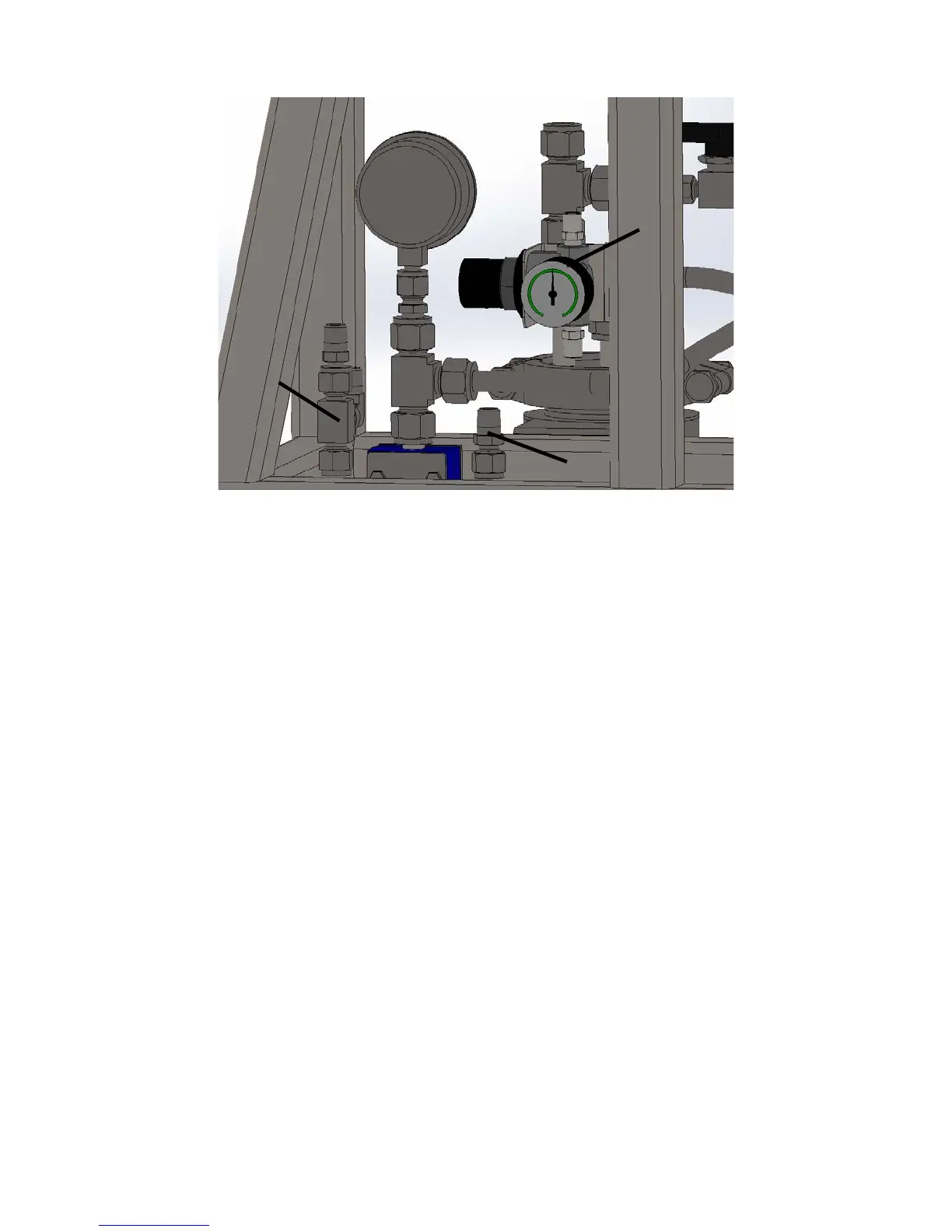

2.1.7. Miscellaneous/Multi-Area Parts

2.1.7.1. Air Actuated Ball Valves – These ball valves are operated automatically by the

controller and the air valve manifold. Indicators on the front of the valve will display the

position of the valve. If the yellow line on the indicator is parallel to the valve body then

the valve is considered open. If the indicator is perpendicular then the valve is closed.

Valve positioning can be verified from the I/O Screen.

2.1.7.2. Relief Valves – Located throughout the system these valves mechanically protect the

system from over pressurizing.

Main Supply and

Recovery Bottles

2

Supply Bottle

Loading...

Loading...