Apeks Supercritical The Duplex™ Operation Manual

7

Revision Date 8/28/2018

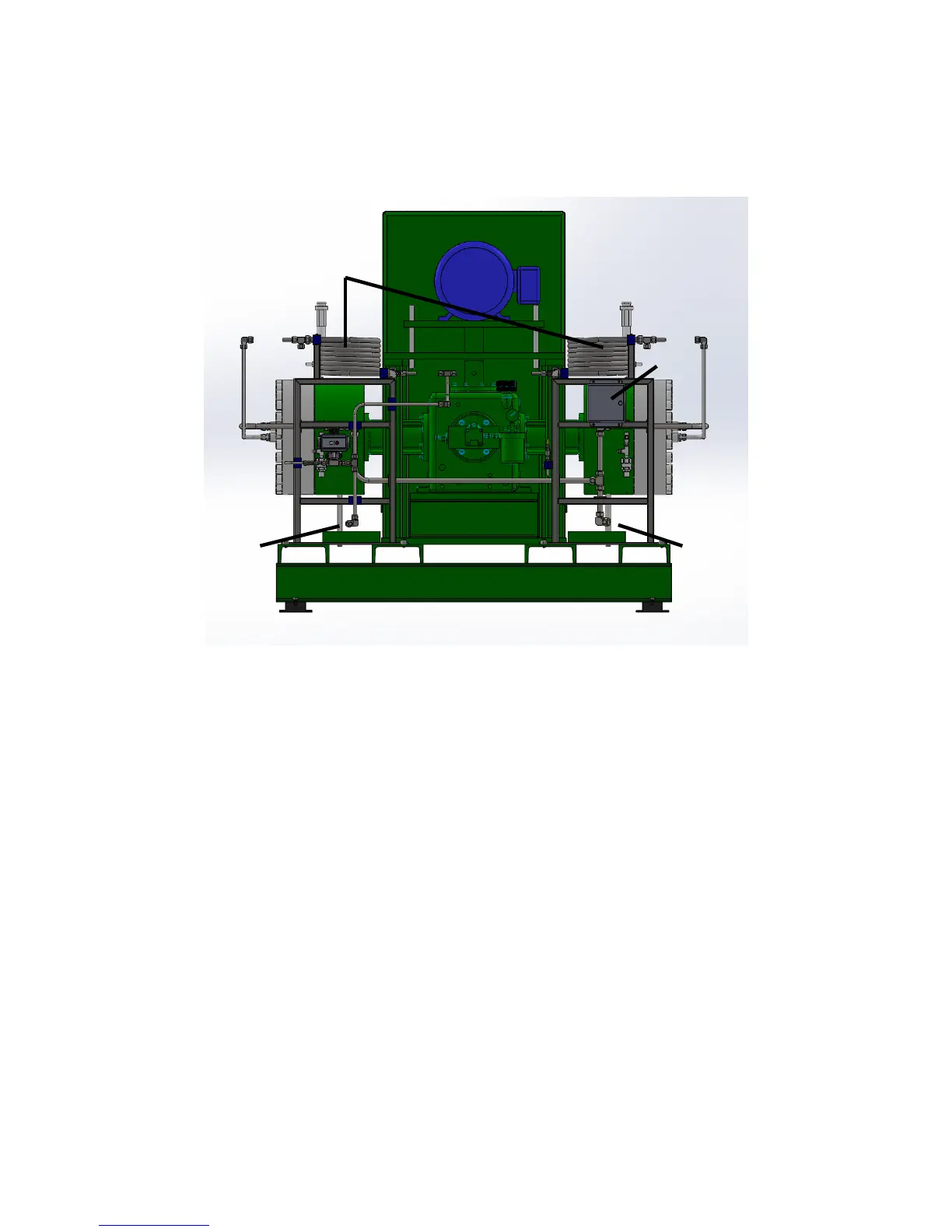

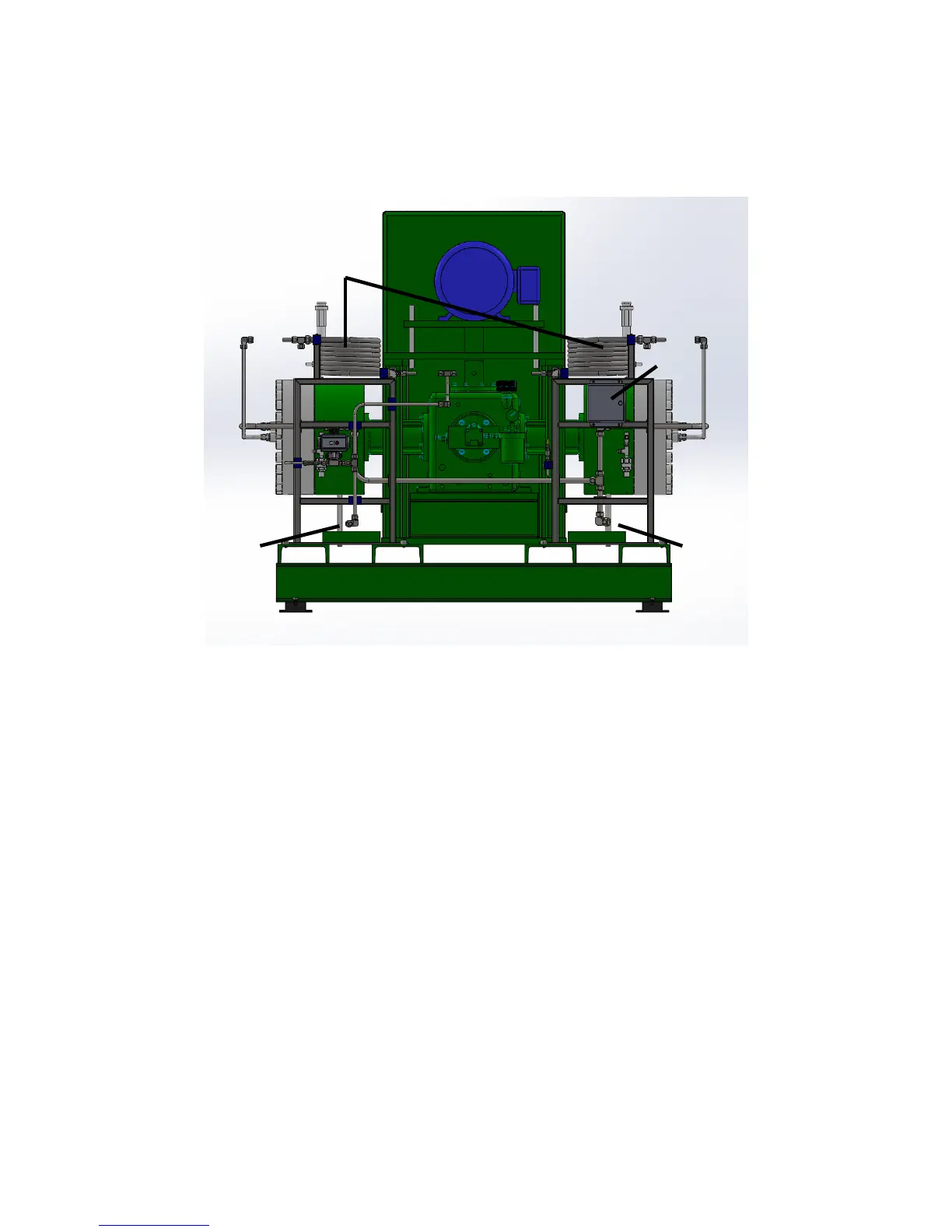

2.1. The Duplex™ System Overview

2.1.1. Diaphragm Compressor – The diaphragm compressor for the Apeks 2000psi Duplex™ system

is dual head compressor where both heads work in parallel to compress CO

2

to the desired

target pressure in the extractors.

2.1.1.1. Gauges on the Compressor

2.1.1.1.1. Oil Pressure Gauges – There are two gauges that display different oil pressures on

the diaphragm compressor. The first is a high-pressure loop that incorporates the oil

heat exchanger and some internal bearings. This gauge should read between 40-50

psi at all times when the system is running. The second is a low-pressure loop that

incorporates the injection pump which supplies oil to the oil compression side of the

diaphragm head. This gauge should read between 15-20 psi when the system is

running.

2.1.1.1.2. Leak Detect Gauges – There is a leak detect switch on each pump head. This

gauge monitors the cavity between the oil side and CO

2

side to ensure that there is

no crossover between the two systems. This gauge should display no pressure. See

Troubleshooting section if this gauge shows pressure.

2.1.1.2. Pressure Switches

2.1.1.2.1. Oil Pressure Switch – The oil pressure switch monitors the low-pressure oil loop to

make sure there is oil flowing in the system. If oil pressure is lost this switch will stop

the system and an alarm will be triggered.

2.1.1.2.2. Leak Detect Pressure Switch – This pressure switch works the same as the leak

detect gauge but continually monitors for the presence of pressure and will shut the

machine down if over 15 psi of pressure detected in the pump cavity.

2.1.1.3. Over Pressure Valve (OPV) and Oil Bypass Valve – The OPV valve on the pump is a

back-pressure regulator. The valve is set to allow the hydraulic oil pressure in the head to

reach a certain point but not go above that point. The Bypass Valve is a needle valve with

2

2

Heat

Exchangers

Loading...

Loading...