Apeks Supercritical The Duplex™ Operation Manual

8

Revision Date 8/28/2018

a black handle that can be opened in order to bypass the OPV. This is done during

priming of the compressor and during head maintenance. (see appendix B)

2.1.1.4. Junction Box – The diaphragm compressor has a single junction box for the pressure

switches that has a Harding Connector (electrical quick-connect) and thermocouples that

go to the main control enclosure.

2.1.1.5. Regenerative Heat Exchangers – There are two regenerative heat exchangers that are

located on the pump, one for each diaphragm head. These heat exchangers remove heat

from the compressed CO

2

to use on the separators.

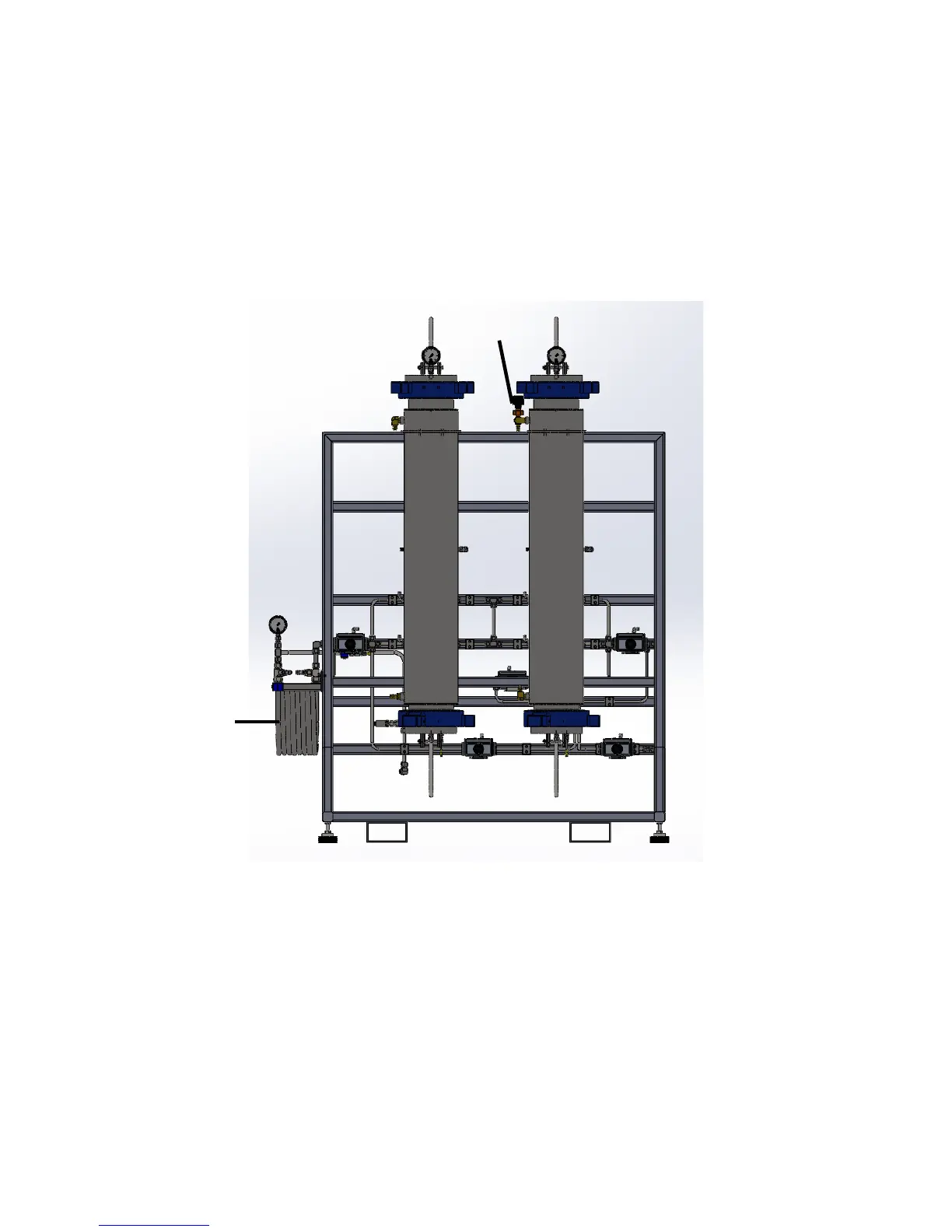

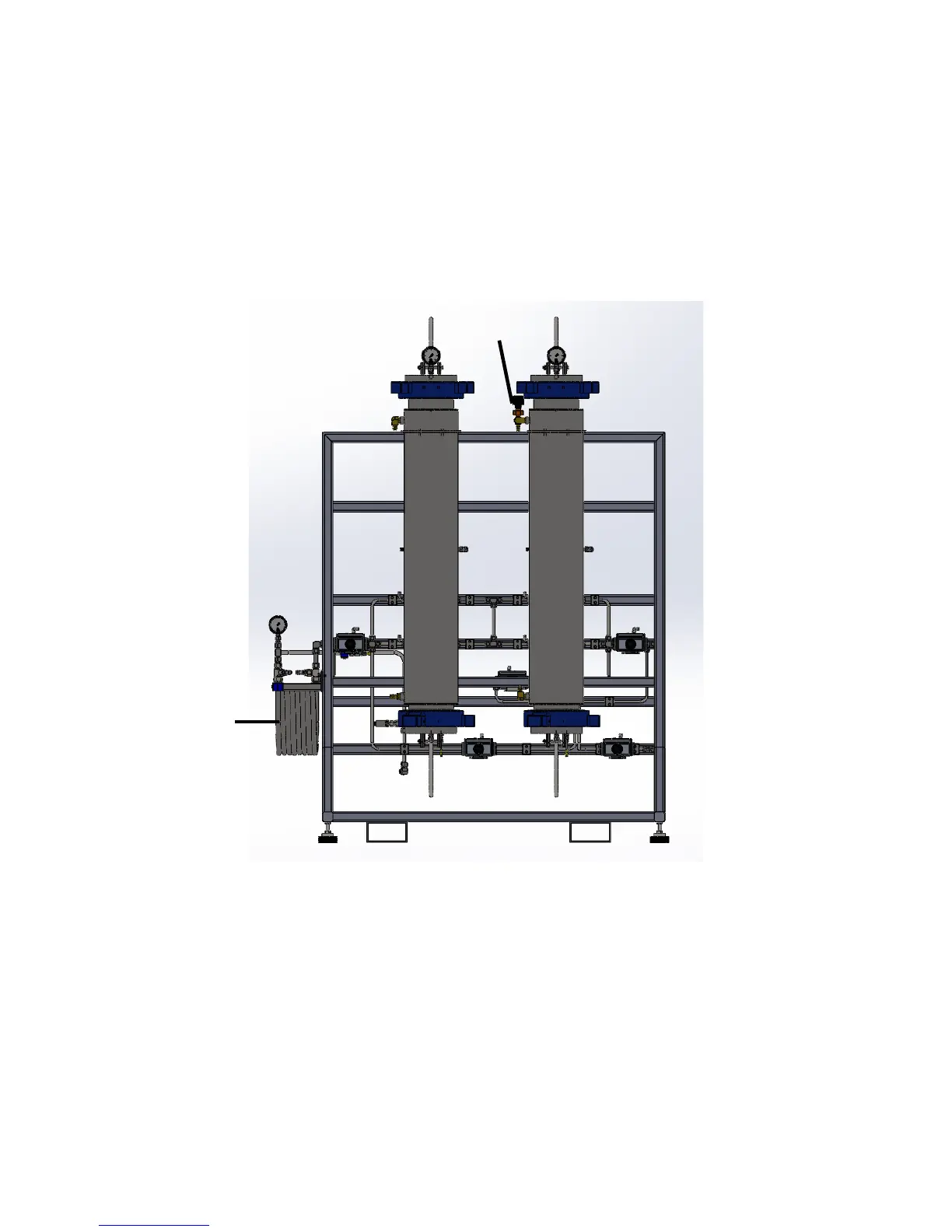

2.1.2. Extraction Vessel Stand

2.1.2.1. Extraction Vessels – There are two extraction vessels on each stand. Vessel A is

located on the right-hand side of the stand and Vessel B is located on the left. These

vessels can be either 5L or 20L and are Hammer Union Closure vessels. This closer

mechanism uses a nut to hold down a cap to allow the vessel to pressurize. Seals on this

vessel are cup style seals which expand with the presence of pressure and create a face

seal on the vessel. Extraction vessels are loaded and unloaded from the top of the

vessel. When loading, unloading and cleaning these vessels be sure to keep face surface

and threads clean. Failure to keep these surfaces clean can cause your vessel not to

seal properly and could cause damage to your cup seal.

2.1.2.2. Locking Vessel Isolation Valves – Each extractor has two locking isolation valves that

should be utilized whenever the operator is working in any vessel. These valves are

A

B

Control Heat

Exchanger

Loading...

Loading...